Casting of Brake Disc and Impeller from Aluminium Scrap Using Silica Sand

Matthew S. ABOLARIN, Oluwafemi A. OLUGBOJI, Oladeji A. OGUNWOLE

Department of Mechanical Engineering, Federal University of Technology, Minna, Niger State, Nigeria

abolarinmatthew@yahoo.com, olugbojioluwafemi@yahoo.com, dejiogunwole@yahoo.com

Abstract

The impeller blade and the brake disc were produced using sand casting method. Wooden patterns of the two castings were constructed incorporating the necessary allowances. Green and moulding technique utilizing locally available materials were used for preparing the moulds. Aluminium scraps were used as the casting material. Melting of the Aluminium scraps was obtained using a crucible furnace and finally pouring the molten metal into the sand mould to obtain the impeller and the brake disc.

After fettling and cleaning, the two casting were found to be good. The casting yield was found to be 73.59% for the impeller blade and 85.1% for the brake disc which indicate that sound casting was achieved.

Keywords

Impeller Blade, Brake Disc, Green Moulding, Crucible Furnace, Fettling

Introduction

Casting refers to the pouring of the molten metal into a mould, in which it cools and solidifies to produce an object of desired shape. However, the main casting methods available include: sand casting, in which liquid is poured into a shape cavity moulded from sand; die casting, in which the mould cavity is machined within metal die block; investment and centrifugal casting also exist. Moulding sand has a fairly low thermal conductivity so that the rate of solidification of liquid metal with a sand mould is fairly slow, given rise to a coarse crystal grain size. This of course makes the use of metallic mould more suitable in order to obtain a fine grain structure.

Metal castings are vital components of most modern machines and transportation vehicles. Cast metals parts accounts for more than ninety percent of the weight of tractor and more than fifty percent of an automobile engine. Above all, casting provides a process of improving the mechanical properties of components or articles. Aluminium is used because it produces casting of good mechanical properties, such as good surface finish, light weight, fewer tendencies to oxidation, lending to modification, resistance to corrosion and its availability. This work covers the casting of brake disc and impeller blade using a properly prepared green sand mould, which is less expensive and gives less distortion and dimensional accuracy. Aluminum alloy is used because of its fluidity and good physical properties.

Theoretical analysis

Both ferrous and non - ferrous alloys can be cast using green sand method especially when greater tonnage of casting is required. The ferrous alloys cast by this process include cast iron and steel. The commonly non - ferrous alloys cast by this process are aluminum base, copper base and magnesium base alloys. The temperature of these alloys ranges from 680°C to 450°C (Mikhailov A. M., 1989).

Melting and pouring are processes of preparing molten metal of the proper composition and temperature in foundary using appropriate melting furnace and pouring the prepared molten metal into the mould from transfer ladles. Furnace melting alloys in the foundry include lift out or tilting crucible furnace. For a particular casting alloy, the temperature of pouring is taken with a certain super heat above its liquids temperature. The super heat is chosen depending on the influence of super heat temperature on the structure and mechanical properties of metal, the thickness and extensions of the walls of casting, the liability of the metals to form films, the thermo - physical properties of the mould material and the initial temperature of the mould material, the forces that cause stirring of hot metal in the mould and other factors. The pouring temperature for aluminium alloy is 680°C - 700°C, for bronzes and brasses is 1000 - 1200°C, for magnesium alloy is 700 - 800°C, for steel is 1520 - 1620°C and for cast iron is 1300 - 1450°C (Howard et al., 1985).

Material and Methods

Material used

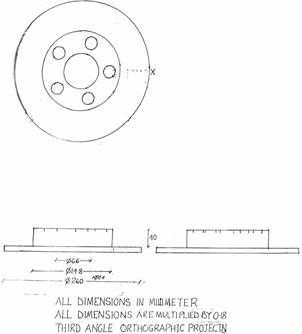

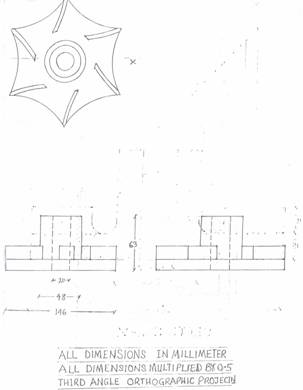

The brake disc of 260mm diameter and 15mm thickness and the impeller of 146mm diameter and 5mm thickness as shown in figure 1 and 2 respectively were cast with the following materials: pattern material, mould material, aluminium scrap, and furnace.

|

|

|

|

Figure 1. Working drawing of the pattern for the cast brake disc |

Figure 2. Working drawing of the pattern for the cast impeller |

Pattern material

A wooden pattern was produced from the developed pattern drawing. A hard wood (mahogany) was use for the production of the impeller pattern. The pattern for the impeller was produced from the wood of initial dimension 200mm · 150mm, putting into consideration the spacing of the characters, depth of each shape using the specified dimension on the patter drawing.

In the case of the blade disc, two plywoods, each 2cm thick of 32cm·32cm were glued and nailed together. A divider opened to a radius of 14cm was used to inscribe a circle in its centre, found by drawing diagonals from the plywood edges. Hardwood of 16cm·16cm·3cm was glued and nailed to the centre of the plywood, and a divider opened to 6.7cm was used to inscribe a circle for the bore to be drilled. Putty was used to fill all chipped imperfections and also in filleting the pattern’s sharp and rough edges, after it was filled to a smooth finish. Two coats of wood varnish were applied.

Figure 1 and 2 shows the working drawings of the patterns for the cast brake and impeller respectively.

Mould material

The mould materials used is the green sand mould and they include the following: silica sand, bentonite, and water. Green sand moulding which was used is a situation where the moulding sand remained moist until the metal is poured into it. Silica sand was sieved to obtain fine grain sized sand and to remove other foreign bodies in the sand. A specific quantity of the sand was fetched and bentonite was added as binder and mixed thoroughly with the sand. Water was then added to the already mixed mixtures, which were then thoroughly mixed together by hand to make ready for mould.

Furnace

The furnace used for the melting of the aluminium scrap is the Morgan furnace, which makes use of diesel oil for burning.

Methods

Aluminium was melted in a crucible furnace, an oldest and simple type of melting equipment. It was poured after melting into the mould earlier prepared for the two patterns. No melting treatment was carried out prior to pouring operation. After the pouring and solidification is completed, the two patterns were removed, cleaned and inspected for possible defects.

Calculations

Impeller

Actual impeller diameter = 146mm, Shrinkage allowance used = 13mm/m, Machining allowance used 6mm.

Diameter of pattern due to shrinkage =

= Impeller Diameter + (Shrinkage Allowance)(Impeller Diameter)

= 146+(13·146/1000) = 146+1898/1000 = 146+1.898 = 147.898mm.

Therefore, adding machining allowance, this diameter of the pattern becomes

Diameter of the pattern =

= Machine allowance + Diameter of pattern due to shrinkage

= 6+147.898 = 153.898mm.

Brake disc

Actual blade disc diameter = 260mm, Shrinkage allowance used = 13mm/m, Machining allowance used = 6mm.

Diameter of the pattern due to shrinkage =

= Disc diameter + (Shrinkage allowance)(Brake disc diameter)

= 260 + (13·260/1000) = 260 +3380/1000 = 260 + 3.38 = 263.38mm

Adding machining allowance, thus diameter of the pattern becomes:

Diameter of the pattern =

= Machine allowance + Diameter of pattern due to shrinkage

= 263.38+6 = 269.38 = 269 mm

Casting Yields - The casting can be evaluated using casting yield, which determines the percentage use of metal in casting.

% Casting Yield = WC/(WC + WG+WR)

Where WC = Casting Weight, WG = Gating Weight, WR = Riser Weight.

For the impeller,

· Casting Weight, WC = 0.418Kg.

· Weight of gating and riser, WG + WR = 0.15Kg.

Casting Yield = 0.418/(0.418+0.15) = 0.418/0.568 = 0.7359 · 100 = 73.59%

For the brake disc,

· Casting Weight = WC = 2.0Kg

· Weight of gating and riser = 0.35Kg

Casting Yield = 2.0/(2.0+0.35) = 2/2.35 = 0.851 · 100= 85.1%

Result and Discussion

A casting free of defects can be obtained if the pattern is properly designed, the mould properly prepared and the melting and pouring processes correctly carried out. In this work, due to unavoidable errors, some defects were noticed on the cast impeller blade and the brake disc. Both the external and the internal surface of the casting were relatively rough compared with the degree of smoothness expected of the brake disc. However, the external surface was machined to obtain a higher degree of smoothness while for internal surface; there was little or nothing which could be done to improve the smoothness. In the case of cast impeller, it was only the edge that was rough. A file was use used in filling the edges in order to smoothen it.

Conclusion

In the course of this work, effort was made to produce locally the impeller and brake disc from aluminum scraps and to ensure that they conform to specification required. The green sand mould prepared gave the rough surface of the two castings, this may be due to the fact that no additives were added or proper percentage composition was not used. The defects found on the two casting may be due to entrapped air and poor surface finish of the mould, though the defects are minor. The cast yield for the impeller and the brake disc indicates that sound casting was achieved.

References

[1] Mikhailow A. M., Metal Casting, First edition Mir Publishers, Moscow, 1989.

[2] Howard E. B., Timothy L. G., Metal Handbook, Desk edition, America Society for Metal (ASM) USA, 1992.