Parametric Variations Sensitivity Analysis on IM Discrete Speed Estimation

Mohamed BEN MESSAOUD* and Abdennaceur KACHOURI

Electronic and Information Technology Laboratory, National Engineering School of Sfax, Tunisia

M.BenMessaoud@enis.rnu.tn (*corresponding author)

Abstract

Motivation: This paper will discuss sensitivity issues in rotor speed estimation for induction machine (IM) drives using only voltage and current measurements. A supervised estimation algorithm is proposed with the aim to achieve good performances in the large variations of the speed. After a brief presentation on discrete feedback structure of the estimator formulated from d-q axis equations, we will expose its performances for machine parameters variations.

Method: Hyperstability concept was applied to the synthesis adaptation low. A heuristic term is added to the algorithm to maintain good speed estimation factor in high speeds.

Results: In simulation, the estimation error is maintained relatively low in wide range of speeds, and the robustness of the estimation algorithm is shown for machine parametric variations.

Conclusions: Sensitivity analysis to motor parameter changes of proposed sensorless IM is then performed.

Keywords

Induction Motor; Speed Estimator; Sensitivity; Parametric Variation; Robustness

Introduction

A high degree of sophistication of new control methods as vector control, adaptive or variable structure control, is reached with the help of special measurement systems (state observers, reconstruction of mechanical or electromagnetic variables).

During the last decay the speed control of induction machine (IM) requires the knowledge of rotor speeds values, therefore in order to replace the mechanical sensors, significant research effort has been devoted to the field of shaft-sensorless control of induction motors. This research is interest on software–based methods of estimating rotor speed of induction motors using electric measurement of the stator current and voltage. Direct and indirect methods are developed to avoid magnetic or mechanical sensors mounted in the motor [1, 2, 3]. It was observed that a speed estimation error can appears when one uses a flux or state observers and then calculate the rotor speed [4,5].

Less error and less sensitivity on parameter variation are noted if one uses the Model Reference Adaptive Systems (MRAS) [6] or sliding mode techniques [7, 8, 9].

Recently, neural identification method is applied to estimate motor speed; it seems to be an interesting solution but it presents some problems in the case of reversal operation of the motor [10]. A novel parallel adaptive observer has been designed, starting from the series-parallel Kreis-selmeier observer [11].

This paper deals with a new class for speed estimation of induction motor. The used structure constitutes the feedback linear time varying structure in its discrete form. The hyperstability of the loop are demonstrated and the stability is guaranteed.

The adaptation algorithm based on current quantities is deduced. The high-performances of such estimator are shown in low speeds and when parameter changes, where the most methods fail.

In the objective of applicability of the algorithm in high speeds, adaptation low is slowly modified by replacing the current by current error.

In simulation, the robustness of the proposed algorithm is checked for variations of the stator and rotor parameters (resistances and inductances).

Feedback structure of the estimator

In order to overcome the stability problem for low speed with parameter variations, we present the structure of the inverse model of the machine in the form of feedback linear time varying structure based on electrical equations described below.

Electrical Equations

Equations for induction motor can be expressed in the stationary d-q frame [6] as:

|

|

(1) |

|

where |

(2) |

|

|

(3) |

The signification of parameters and variables appear in appendix I.

Discretization

A discretized version suitable for digital implementation is developed, preserving the characteristics of the original continuous-time procedure.

The discrete form of equations (1-2 and 3) is given by:

|

|

(4) |

|

|

(5) |

|

|

(6) |

where

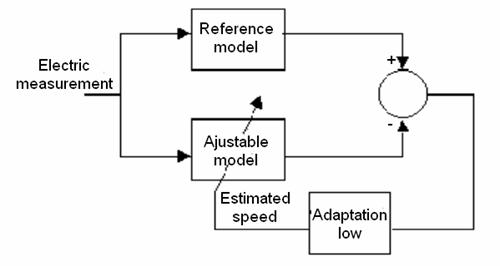

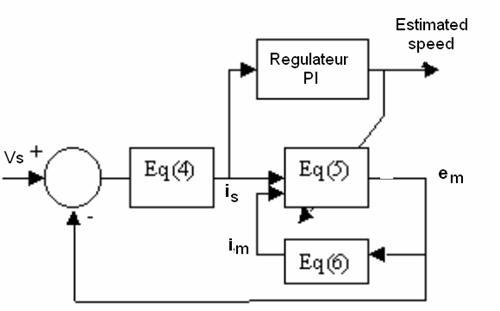

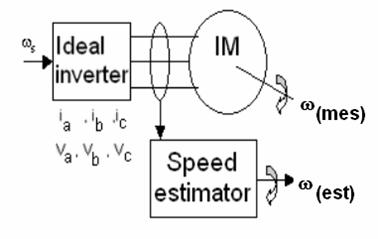

Figure 1 illustrates the conventional adaptive structure. The proposed structure is described by equations (4), (5) and (6). These equations constitute a feedback time varying parameters system represented by the bloc diagram of the proposed speed estimator of the figure 2. The input is the vector vso = [vsod, vsoq]T and the output is the estimated speed of induction machine.

In counter part of conventional nonlinear structure, the present strategy presents a dynamic which depends only on the values of a transition state matrix of the feedback system.

Figures 1 and 2 illustrate the difference between conventional adaptive structure and the proposed structure.

Figure 1. Diagram of conventional Adaptive speed estimator

Figure 2. Diagram of proposed speed estimator

Hyper-stability of feedback structure

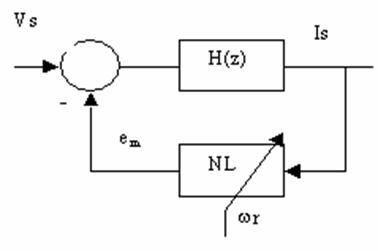

In this section, we briefly review the use of hyperstability concept [12] to the synthesis of adaptation low. The hyperstability analysis of nonlinear systems requires a linear time invariant discrete transfer function H(z) in the feedforward path, and a nonlinear block in the feedback one (figure 3).

Figure 3. Configuration of feedback system

Hyperstability Theorem [13]:

The non linear feedback system of the figure 3 is hyperstable if:

· The linear time invariant discrete matrix H(z) is real positive; i.e.

o all poles of elements of H(z) lies in unitary circle

o the matrix H(z)+H(z*) is a positive semi definite Hermitian matrix for all½z½=1, the star indicates the complex conjugate.

· In the non-linear feedback part, the following inequality of Popov (7) holds; i.e.

|

|

(7) |

Synthesis of adaptation low

By substituting equations (4), (5) in inequality (7), one can write:

|

|

(8) |

Under steady state and the following approximation:

|

|

(9) |

Equation (7) becomes:

|

|

(10) |

Let’s take the Integral adaptation law as:

|

|

(11) |

Without loss of generality, letting wr(0)=0 and replacing (11) in (10), yields:

|

|

(12) |

Using the relation (13),

|

|

(13) |

One obtains the particular solution for y as follows

|

|

(14) |

where k is a positive and constant.

|

|

(15) |

where Q is any positive real.

Taking into account the adaptation mechanism (15), Popov inequality (7) is hold and the hyperstability is guaranteed for the nominal parameters and in the unloaded motor case.

Performance analysis

The speed estimation algorithm described in Equation (15) is tested in the wide range of speed and torque variations and the machine parameter variation is also considered to evaluate the performance of the algorithm.

Simulation conditions

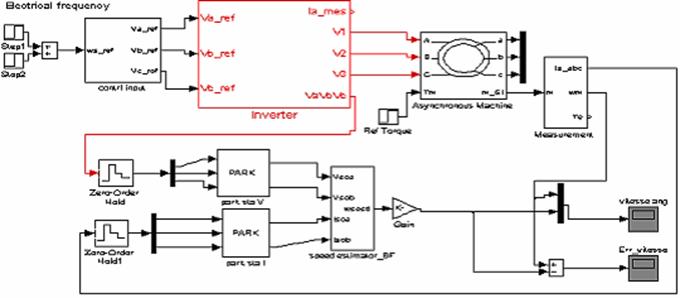

To achieve the following simulation results, Matlab- Simulink software is used to simulate the hardware and the software parts.

The simulation block diagram is represented in figure 4 where the ideal voltage inverter is used and the Open loop speed control is applied.

The voltage and current measurement quantities constitute the inputs of the algorithm to estimate the motor speed.

Figure 4. Simulation scheme

The motor is trained by electrical frequency ws, therefore the correspondent trajectory of the motor speed is deduced. The reference speed of the motor is changed at different time instant as illustrated in table 1.

Table 1. Reference speed variation.

|

Scale of speed |

Low speed |

Middle speed |

Nominal speed |

Stop position |

|

Time range (s) |

0-1 |

2-2.5 |

3-3.5 |

4.5-5 |

|

Reference speed value (rad/s) |

10 |

50 |

150 |

0 |

The figure 5 illustrates the detailed diagram of simulation using the Matlab- simulink blocks.

Figure 5. Matlab- simulink diagram for simulation

Simulation Results

The proposed estimation algorithm generates the estimated speed for a power motor of 1.5 kW, the rated torque 7 Nm and the rated speed 1420 rpm. The open loop control is applied for the motor, in order to give the profile of the measured speed.

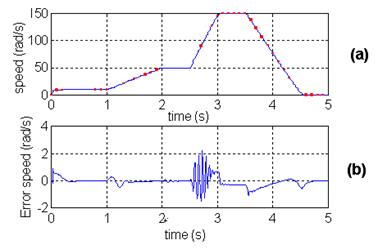

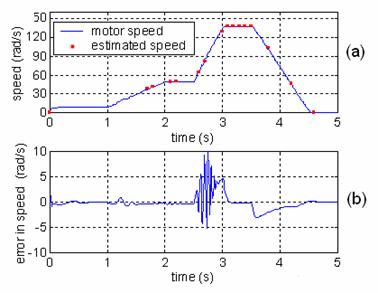

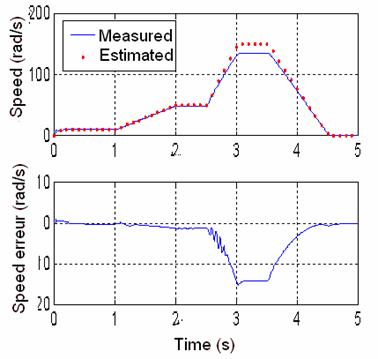

Figures 6 and 7 evaluate the performances of the algorithm in the cases of unloaded motor and for +50% rotor resistance variations.

Remarks

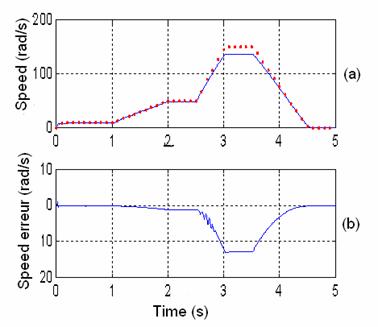

In unloaded torque case, the figure 6(a) presents the evolution of motor speed and estimating one for different values (low and high speeds). Simulation reveals negligible steady state errors as illustrated in figure 6 (b).

For unloaded machine the speed is estimated perfectly [14].

Figure.6. Typical parameters: unloaded motor (a) measured and estimated speed.

(b) error on speed estimator

Figure.7. Deviation of +50 % in Rs; unloaded motor (a) measured and estimated speed.

(b) error on speed estimator

Sensitivity of the algorithm to parameter variation

To evaluate the influence of the parametric variation to estimated speed, we introduce the following performances indexes expressed in percent:

The Percent of Root-mean-square Difference (PRD):

|

|

(16) |

And the steady state error es,:

|

|

(17) |

where wmot is the actual speed of the motor and west is its estimation.

Table 2 shows that the estimated speed is not affected by the parameter variations, than it is obvious that the proposed algorithm gives satisfactory results.

Table 2. Performances of the PI estimation for parametric deviation in the case of unloaded machine

|

Parameter |

PRD (%) |

steady state error (%) |

||

|

wmot = 10 rad/s |

wmot = 50 rad/s |

wmot = 150 rad/s |

||

|

Rated |

0.45 |

-0.0032 |

-0.02 |

-0.18 |

|

0,5 Rs 1,5 Rs |

0.97 0.56 |

-0.0548 -0.0045519 |

-0.0364 -0.0214 |

-0.18 -0.18 |

|

0,5 Lls 1,5 Lls |

0.29 0.46 |

-0.0032419 -0.00317 |

-0.02 -0.0204 |

-0.17 -0.19 |

|

0,5 Rr 1,5 Rr |

1.05 0.56 |

-0.00395 -0.0044 |

-0.009 -0.0294 |

-0.08 -0.28 |

|

0,5 Llr 1,5 Llr |

0.52 0.47 |

-0.0032 -0.00324 |

-0.02 -0.02 |

-0.18 -0.18 |

|

0,5 M 1,5 M |

0.51 0.70 |

-0.0059 0.0154 |

-0.0244 -0.0187 |

-0.2 -0.18 |

Load effect on the proposed algorithm

The behavior of the speed estimator of induction motor with a mechanical load equal to 200% of its nominal value is checked.

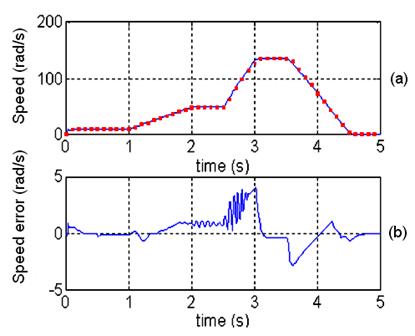

Figure 8 shows the influence of the load in the case of nominal parameters and the figure 9 for +50% variations on the stator resistance referring to its nominal value.

Figure 8. Effect of the load torque on the estimation algorithm: (top) measured and estimated speeds; (bottom) estimation error

Figure 9. Effect of deviation +50% Rs in the case of loaded motor: (top) measured and estimated speeds; (bottom) estimation error

In the following, table 3 presents the quadratic error and the steady state error for low and high speeds with the machine parameters variations.

Table 3. Performances of the PI estimation for parametric deviation for the case of loaded machine

|

parameter |

PRD (%) |

steady state error (%) |

||

|

wmot = 10 rad/s |

wmot = 50 rad/s |

wmot = 150 rad/s |

||

|

nominal |

7.8 |

-0.876 |

-2.63 |

-9.37 |

|

0,5 Rs 1,5 Rs |

7.23 8.7 |

-0.64 -1.38 |

-2.52 -2.81 |

-8.52 -10.5 |

|

0,5 Lls 1,5 Lls |

7.4 8.2 |

-0.85 -0.9 |

-2.52 -2.74 |

-8.87 -9.91 |

|

0,5 Rr 1,5 Rr |

3.9 11.9 |

-0.43 -1.32 |

-1.3 -4.0 |

-4.47 -14.7 |

|

0,5 Llr 1,5 Llr |

7.8 18.7 |

-0.876 -0.876 |

-2.63 -2.63 |

-9.3 -9.46 |

|

0,5 M 1,5 M |

8.6 7.56 |

-2.11 -0.63 |

-3.12 -2.5 |

-10.4 -9.05 |

Referring to the table 3, the simulation results show the dependence of estimation error and the speed. We note that the relative error increases until 10% in the nominal speed as shown in figure 8.

Discussion

The analysis of the tables 2 and 3 shows that the parameter variations practically do not affects the estimated speed. However, the machine load is the preponderant factor which affects the estimated speed. It is to be noted that the motor load is not considered in the algorithm. Therefore, the influence of the load appears clearly in high speed.

Modified algorithm

To overcome the error introduced by the load, we introduce a correction signal depending on the load in the adaptation low. The current components is are replaced by the current error es in the high speed and the adaptation mechanism is described by (18):

|

|

(18) |

where:

P is any positive integer parameter which increases with the speed;

iso , is are measured and calculated currents.

The input vector of the estimation algorithm becomes [vsod vsoq isod isoq]T .

Parameter Sensitivity and Simulation Results

To study the influence of parameter deviation on the performance of the modified estimation speed algorithm, we will take a variation of ± 50% of each machine parameter.

Unloaded motor TL=0

Table 4 represents the performance indexes evaluated earlier for different values of the desired speed and for different variations on motor parameters.

Table 4. Performance of the modified algorithm for parameter variations in the unload motor case

|

Parameter |

PRD (%) |

Steady state error (%) depending on wmot |

||

|

10 rad/s |

50 rad/s |

150 rad/s |

||

|

Nominal |

2.11 |

-0.0032 |

0.0992 |

0.196 |

|

0,5 Rs 1,5 Rs |

2.33 1.82 |

-0.0546 -0.0046 |

-0.769 0.846 |

0.0069 0.383 |

|

0,5 Lls 1,5 Lls |

2.24 2.03 |

-0.0032 -0.0032 |

0.135 0.065 |

0.218 0.176 |

|

0,5 Rr 1,5 Rr |

2.70 1.65 |

-0.0039 -0.0044 |

0.115 0.098 |

0.301 0.098 |

|

0,5 Llr 1,5 Llr |

2.21 2.6 |

-0.0032 -0.0032 |

0.097 0.101 |

0.196 0.196 |

|

0,5 M 1,5 M |

2.89 2.51 |

-0.0059 0.0154 |

2.60 -0.301 |

1.13 0.052 |

Referring to table 4, it is obvious that the modified algorithm gives satisfactory results in the case of unloaded motor. The estimation error does not access 0.3% in most cases.

Overloaded motor: 200 % of rated load

The behavior of the modified speed estimator of the induction motor is checked with a mechanical load equal to 200% of its nominal value.

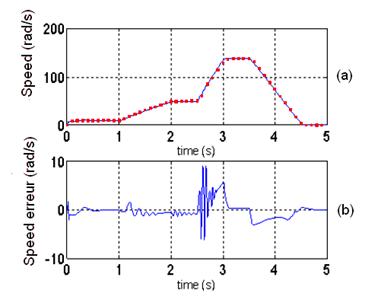

Figures 10 and 11 illustrate the measured and the estimated speeds when the stator resistance varies in the range of -50% to +50% of Rs of nominal value.

The simulation result shows that it is not possible clearly to distinguish between measured and estimated speed. Thus, the estimation steady state error is less than 0.3 rad/s for rated speed.

Figure 10. Loaded motor: 200% of nominal torque (a) Measured and estimated speed for -50% variation on Rs (b) Estimation error

Figure 11 (a) Measured and estimated speed for +50% variation on Rs and for 200% motor nominal load; (b) Estimation error

The table 5 summarizes the performance of the modified estimator in the case of over loaded motor and for the parameter variations.

Table 5. Performance of the modified algorithm for parameter variations in the overload motor case

|

Parameter |

PRD (%) |

Steady state error (%) |

||

|

wmot = 10 rad/s |

wmot = 50 rad/s |

wmot = 150 rad/s |

||

|

Nominal |

2.08 |

-0.876 |

0.427 |

0.0344 |

|

0,5 Rs 1,5 Rs |

2.63 1.74 |

-0.640 -1.38 |

-1.22 1.96 |

0.191 -0.30 |

|

0,5 Lls 1,5 Lls |

2.24 1.99 |

-0.855 -0.897 |

0.617 0.237 |

0.453 -0.424 |

|

0,5 Rr 1,5 Rr |

4.96 3.96 |

-0.434 -1.32 |

1.79 -0.857 |

4.52 -4.88 |

|

0,5 Llr 1,5 Llr |

2.13 2.06 |

-0.876 -0.876 |

0.404 0.446 |

0.0344 0.017 |

|

0,5 M 1,5 M |

5.03 2.35 |

-2.12 -0.63 |

12.4 -0.53 |

1.09 -0.133 |

The analysis of the table 5 shows the efficiency of the proposed algorithm with respect to the variations of Rs, Ls and Lr for all range of speeds; in fact the relative error doesn't access 0.3%.

Thus, the robustness of the proposed algorithm for all range of speeds is guaranteed. On the other hand, its sensitivity to the variation of Rr is acceptable for the high speeds; it is in the order of 4%. The only case where a relatively error appeared is the case of the reduction of 50% of M for the middle speeds (these error remains limited). Consequently, the robustness of the modified algorithm to parametric variation is shown for all the range of speeds.

Conclusions

The feedback structure of estimation speed algorithm is presented. It is fairly general and would seem to be the natural extensions to nonlinear adaptive structure case of estimation speed of induction machines.

It is to be noted that the advantages of the previous structures are believed maintained.

In this paper, the discrete form adapted to the implementation purpose is developed and the stability analysis is performed using the hyper stability theory.

In the case of unloaded motor, simulation results show the robustness of the algorithm to the motor parameter variations (Rs, Ls, Rr, Lr and M).

For torque load, it is shown that estimation errors that are not present in the previous case occur for high speeds. The presence of load disturbs the estimated speed.

The high-speed problems are remedied by a careful choice of standard relation. This is done by adding the term 'stator current components', which depending on the torque.

Finally, simulation examples are considered to illustrate the advantages that can be gained by using the modified algorithm. There was proved that the proposed adjustable low is able to estimate the proper values of the rotor speed even in the case of parameter and speed errors.

The estimation speed algorithms have proven to be a powerful tool in order to give the real induction motor speeds. Special attention must be designed when the mutual inductance decreases.

Appendix I

L = M2/Lr = Equivalent mutual inductance

s = 1-M2 /LsLr = leakage factor.

Electrical variables

· vs = [vsd vsq]T = stator voltage vector.

· is = [isd isq]T = stator current vector.

· ir = [ird irq]T = rotor current vector.

· im =[imd imq]T = magnetizing current vector.

Electrical parameters

· Rs = 4.58 W, Ls = 253 mH = stator resistance and inductance

· Rr = 4.58 W, Lr = 253 mH = rotor resistance and inductance

· Tr = Lr/Rr = rotor time constant inductance

· M = 242.3 mH = mutual inductance

· Lls = Ls-M = stator leakage inductance

· Llr = Lr-M = rotor leakage inductance

Mechanical variable and parameters

· wr = rotor electric angular velocity (150 rad/s rated)

· F = 0.0026 kgm2/s = friction coefficient.

· J = 0.023 kgm2 = moment the inertia

Matrix notation

· In×n = n×n identity matrix

·

![]() = orthogonal rotation matrix

= orthogonal rotation matrix

References

1. L. Ying and N. Ertugrul, A new algorithm for indirect position estimation in permanent magnet AC motors, IEEE 33rd Annual Power Electronics Specialists Conference, PESC 02, Volume: 1, 2002.

2. Nguyen M. T., Sathiakumar S., Shrivastava Y., Speed Estimation for Induction Machine, 8th Int. Power Electronics and Motion Control Conference PEMC'98, Prague, Sept 1998.

3. Kubota H., Mutsise K., Nakano T., DSP- Based Speed Adaptive Flux Observer Of Induction Motor, IEEE Trans. Ind. Appl., 1993, 29(2), p. 344-348.

4. Thongam J. S., Thoudam V. P. S., Stator Flux Based Speed Estimation of Induction Motor Drive using EKF, Journal of Research of Institution of Electronics and Telecommunication Engineers, India, 2004, 50(3), p. 191-197.

5. Harnefors L., Instability Phenomena In Sensorless Control Of Induction Motors, EPE'99, Lausanne, 1999.

6. Peng F. Z., Fukao T., Robust speed identification for speed sensorless vector control of induction motors, IEEE Trans. on Ind. Appl., 1994, 30(5), p. 1234-1240.

7. C. Lascu, I. Boldea, and F. Blaabjerg, Direct torque control of sensor-less induction motor drives: A sliding-mode approach, IEEE Trans. Ind. Appl., vol. 40, no. 2, pp. 582–590, Mar./Apr. 2004.

8. J. Li, L. Xu, and Z. Zhang, An Adaptive Sliding-Mode Observer for Induction Motor Sensorless Speed Control, IEEE Trans. Ind. Appl., vol. 41, no. 4, July./Aug. 2005.

9. A. Derdiyok, M. K. Guven, H. Rehman, N. Inanc, and L. Xu, Design and implementation of a new sliding-mode observer for speed-sensor-less control of induction machine, IEEE Trans. Ind. Electron., vol. 49, no. 5, pp. 1177–1182, Oct. 2002.

10. Orlowska-Kowalska T., Pawlak M., Induction motor speed estimation based on neural identification method, 6th International conference ELECTRIMACS 99, Sept 14-16, Lisboa- Portugal, 1999.

11. Castaldi P., Tilli A., Parameter Estimation Of Induction Motor At Standstill with Magnetic Flux Monitoring, IEEE Trans. on Cont. Syst. Tech., 2005, 13(3), p.386-400.

12. Popov V. M., Hyperstability of automatic control systems, Springer-Verlag, New York, 1973.

13. Landau Y. D., Adaptive control-the model reference approach, Marcel Dakker.Inc, New York, 1979.

14. M. Ben Messaoud, Robustness Of Speed Estimator Of Induction Motors, Int. Conf. on Smart Systems & Devices, SSD'2001, Hammamet, Tunisia, 2001.