Effects of Rice Husk Ash on Some Geotechnical Properties of Lateritic Soil

Fidelis O. OKAFOR1 and Ugochukwu. N. OKONKWO2

1 Department of Civil Engineering, University of Nigeria, Nsukka, Nigeria.

2 Department of Civil Engineering, Michael Okpara University of Agriculture, Umudike, Nigeria.

E-mails: ugokon2003@yahoo.com, okaforfo@yahoo.com

Abstract

The study is an investigation into the effect of RHA on some geotechnical properties of a lateritic soil classified as A-2-6 (0) or SW for sub-grade purposes. The investigation includes evaluation of properties such as compaction, consistency limits and strength of the soil with RHA content of 5%, 7.5%, 10% and 12.5% by weight of the dry soil. The results obtained show that the increase in RHA content increased the OMC but decreased the MDD. It was also discovered that increase in RHA content, reduced plasticity and increased volume stability as well as the strength of the soil. 10% RHA content was also observed to be the optimum content.

Keywords

Rice Husk Ash (RHA); Lateritic soil; Sub-grade; Maximum Dry Density (MDD); Optimum Moisture Content (OMC); California Bearing Ratio (CBR); Consistency indices.

Introduction

In countries of the tropics and subtropics, lateritic soils are encountered in various engineering projects. In the Precambrian times, Nigeria consisted of uplifted continental landmass made up of basement sediments [1]. This resulted in the formation of lateritic soils which are of relatively good quality for road construction works.

Rice husk is an agricultural waste obtained from milling of rice. About 108 tons of rice husk is generated annually in the world. In Nigeria, about 2.0 million tons of rice is produced annually. Rice husk ash has so much been utilized in the past for upgrading of soils [2-6]. In most cases the RHA was used as an admixture and a stabilizing agent (cement or lime) included to increase the cementitious property of the stabilized matrix. It has been shown that both cement and RHA reduced the plasticity of soils and MDD but increased OMC [5]. In the work carried out by [2], the results indicated that cement and RHA used as overall binder system for stabilized/solidified lead-contaminated soils is more favourable in reducing leachability of lead from the treated samples than a binder system of only cement. RHA was used on a Malaysian soil with cement and lime as stabilizing agents [7]. The results showed that based on the strength development, it seems that lime is the more effective stabilizing agent. It was also clearly stated that the RHA can only be used as a partial replacement for the more expensive stabilizing agents (cement/lime) because it has inadequate cementations property required to bind the material to a satisfactory durability.

However, the previous works with RHA have shown that it has promising potentials of improving the engineering properties of soils for sub-grade purposes. Thus, this work focused on investigating the effect of RHA on some geotechnical properties of lateritic soil which are relevant for evaluating the performance of sub-grade soils.

Materials and Methods

The soil sample used for this study was collected from Obukpa in Nsukka Local Government Area of Enugu state in Nigeria, using the method of disturbed sampling. The RHA was ground and sieved through 75μmor 0.075mm aperture before use. The oxide composition of RHA is shown in Table 1.

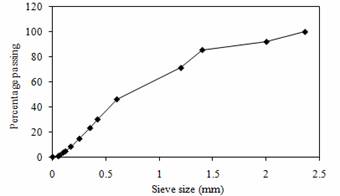

The preliminary tests for identification of the lateritic soil (results shown in Table 2 and Figure 1) as well as the tests for determination of the geotechnical properties of the lateritic soil treated with RHA were carried out in accordance with [8]. The standard Proctor was used for compaction test which was also used to determine the moisture content for the CBR specimens. The RHA was thoroughly mixed with pulverized lateritic soil and then with distilled water. The clay mineral identification was done using plasticity chart developed by Casagrande data in [9]. The properties and grading curve of the lateritic soil are shown in Table 2 and Figure 1 respectively.

Table1. Oxide Composition of Rice Husk Ash

|

Constituents |

Composition (%) |

|

Al2O3 |

4.9 |

|

SiO2 |

67.3 |

|

Fe2O3 |

0.95 |

|

CaO |

1.36 |

|

MgO |

1.81 |

|

Loss on Ignition (LOI) |

17.78 |

Table 2. Properties of the Lateritic Soil

|

Soil property |

Test results |

|

Specific gravity |

2.50 |

|

Liquid limit, LL (%) |

35.20 |

|

Plastic limit, PL (%) |

18.13 |

|

Plasticity index, PI (%) |

17.07 |

|

Linear shrinkage |

13.08 |

|

Maximum Dry Density (kg/m3) |

2040 |

|

Optimum Moisture Content (%) |

13.80 |

|

Percent passing BS NO 200 sieve |

1.5 |

|

California Bearing Ratio (CBR) |

22.05 |

|

AASHTO classification(1) / USC classification(4) |

A-2-6(0) / SW |

|

Major clay mineral |

Illite |

Figure 1. Grading Curve for the Lateritic Soil

Results and Discussions

Compaction characteristics

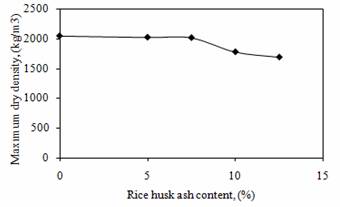

Figure 2 shows the relationship between the MDD and RHA contents. The results indicated that between 0% and 12.5% RHA contents, the MDD reduced from 2040Kg/m3 to 1689Kg/m3 respectively. The reduction may be attributed to the replacement of soil by RHA in the mixture which has relatively lower specific gravity of 2.25 compared to that of the soil which is 2.50. It may also be attributed to the coating of the soil by the RHA which results to large particles with larger voids and hence less density [10].

Figure 2. Variation of Maximum Dry Density with Rice Husk Ash Content

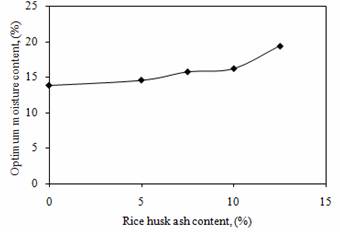

Figure 3, shows the variation of OMC with RHA content. The result shows that the OMC increased with increase in RHA content. This trend may be attributed to the addition of RHA which decreased the quantity of free silt and clay fraction and forming coarser materials with larger surface areas (these processes need water to take place). This implies also that more water was needed in order to compact the soil-RHA mixtures [11].

Consistency limits

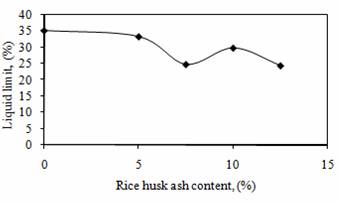

The relationship between liquid limit and RHA content is shown in Figure 4. The liquid limit decreased from 35.20% to 24.80% with increase in RHA content from 0% to 7.5% respectively. This can be considered to be as a result of the replacement of the soil fines by RHA. The later which has less affinity for water, caused the drop in liquid limit. As the RHA was further increased from 7.5% to 10%, the liquid limit increased from 24.80% to 29.85% respectively. At this stage the RHA quantity increased to the extent that more water will be required to turn the soil-RHA mix to fluid.

Figure 3. Variation of Optimum Moisture Content with Rice Husk Ash Content

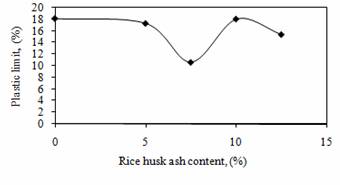

Figure 5, shows the relationship between plastic limit and RHA content. The trend is similar to that of the liquid limit. The reasons for the variation of liquid limit with RHA content are also similar to that of the variation of plastic limit with RHA content.

Figure 4. Variation of Liquid Limit with Rice Husk Ash Cintent

Figure 5. Variation of Plastic Limit with Rice Husk Ash Content

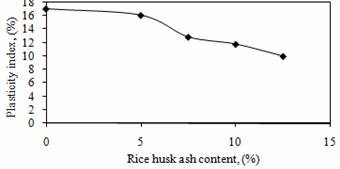

Figure 6. Variation of Plastic Index with Rice Husk Ash Content

Plasticity Index and RHA content relationship is shown in figure 6, the plasticity index decreased from 17.07% to 10.02% with increase in RHA content from 0% to 12.5%. This trend may be attributed to the replacement of the finer soil particles by the RHA with consequent reduction in the clay content and plasticity index. It was also observed that plasticity index of a soil increased as the amount clay fraction increased and vice versa [12].

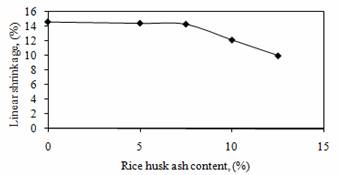

In figure 7, the linear shrinkage decreased from 14.60% to 10.00% with increase in RHA content from 0% to 12.5%. This may be attributed to the usual replacement of the soil fines by RHA. The later is less in activity with changes in moisture content and therefore, reduced the linear shrinkage of the soil-RHA mix. This enhances volume stability of the soil.

Figure 7. Variation of Linear Shrinkage with Rice Husk Ash Content

Strength characteristics

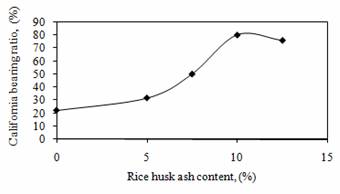

Figure 8 shows the relationship between CBR and RHA content. The result shows that the CBR increased from 22.05% to 80.14% with increase in RHA content from 0% to 10% respectively and subsequently reduced with further addition of RHA. The reason for increment in CBR may be because of the gradual formation of cementitious compounds in the soil by the reaction between the RHA and some amounts of CaOH present in the soil. The decrease in CBR above 10% RHA content may be due to extra RHA that could not be mobilized for the reaction which consequently occupies spaces within the sample. This reduced the bond in the soil-RHA mixture. The CBR is a measure of the strength of the sub-grade and 10% RHA content gave the highest improvement of the CBR of the soil and hence would appear to be the optimum RHA content.

Figure 8. Variation of California Bearing Ratio with Rice Husk Ash Content

Conclusions

The following conclusions may be drawn from the study:

1. The soil was classified to be A-2-6(0) or well-graded sand (SW).

2. RHA increased the OMC but decreased the MDD of the soil.

3. The increase in RHA content decreased the plasticity index of the soil. This confirms that the activity of the mixture reduced with the addition of RHA.

4. The addition of RHA increased the volume stability of the soil.

5. The addition of RHA improved the strength property (CBR) of the soil.

6. 10% RHA content was observed to be the optimum content for the lateritic soil.

7. From the foregoing investigation it would appear that RHA perform satisfactorily as a cheap stabilizing agent for lateritic soil for sub-grade purposes.

References

1. Kogbe C. A., Preliminary Interpretation of Gravity Measurements in the Middle Niger Basin Area, Nigeria. Geology of Nigeria, the Elizabethan publishing, 1975.

2. Yin Chun-Yang, Mahmud H.B. and Shaaban M.G.; Stabilization/solidification of Lead- Contaminated Soil using Cement and Rice Husk Ash. Journal of Hazardous Materials, 2006, 137(3), p.1758-1764.

3. Oyetola E. B., Abdullahi M., The Use of Rice Husk Ash in Low-cost Sandcrete Block Production, Leonardo Electronic Journal of Practices and Technologies, 2006, 8, p. 58-70.

4. Haji Ali F., Adnan A., Chew K. C., Geotechnical Properties of a Chemically Stabilized Soil from Malaysia with Rice Husk Ash as an Additive, Journal of Geotechnical and Geological Engineering, 1992, 10(2), p.117-134.

5. Basha E. A., Hashim R., Mahmud H. B., Muntohar A. S., Stabilization of Residual Soil with Rice Husk Ash and Cement. Construction and Building Materials, 2005.

6. Al-Khalaf M. N., Yousif H. A., Use of Rice Husk Ash in Concrete. The International Journal of Cement Composites and Light-weight Concrete, 1984, 6(4), p. 241-248.

7. ASTM: Soil and Rock; Dimension Stone; Geosynthetics. Annual book of ASTM Standards, ASTM, Philadelphia, USA, 1993.

8. BS 1377: Methods of Testing Soils for Engineering Purpose. British Standard Institute, London, UK, 1990.

9. Mitchell J. K.; Fundamentals of Soil Behaviour. John Wiley & Sons, Inc., New York, USA, 1976

10. Osula D. O. A.; Lime Modification of Problem Laterite, Engineering Geology, 1991, 30, p. 141-149.

11. Osinubi K. J., Evaluation of Admixture Stabilization of Nigerian Black Cotton Soil. Nigeria Society of Engineers Technical Transactions, 1976, 34(3), p. 88-96.

12. Arora K. R., Soil Mechanics and Foundation Engineering (Geotechnical Engineering), Standard Publishers Distributors, Delhi, India, 2008.