Performance of Recycled Asphalt Pavement as Coarse Aggregate in Concrete

Fidelis O. OKAFOR

Department of Civil Engineering, University of Nigeria, Nsukka, Nigeria

E-mail: fidelis.okafor@unn.edu.ng

Received: 7 August 2010 / Accepted: 20 December 2010 / Published: 24 December 2010

Abstract

Recycled asphalt pavement (RAP) is the reclaimed and reprocessed pavement material containing asphalt and aggregate. Most RAP is recycled back into pavements, and as a result there is a general lack of data pertaining to the mechanical properties for RAP in other possible applications such as Portland cement concrete. In the present study, some mechanical properties of Portland cement concrete containing RAP as coarse aggregate were investigated in the laboratory. Six concrete mixes of widely differing water/cement ratios and mix proportions were made using RAP as coarse aggregate. The properties tested include the physical properties of the RAP aggregate, the compressive and flexural strengths of the concrete. These properties were compared with those of similar concretes made with natural gravel aggregate. Results of the tests suggest that the strength of concrete made from RAP is dependent on the bond strength of the “asphalt-mortar” (asphalt binder-sand-filler matrix) coatings on the aggregates and may not produce concrete with compressive strength above 25 MPa. However, for middle and low strength concrete, the material was found to compare favorably with natural gravel aggregate.

Keywords

Recycled asphalt; Portland cement; Concrete; Compressive strength; Flexural strength; Asphalt-mortar

Introduction

Concrete is one of the most widely used construction material today. The concrete consists at least 75% by volume of aggregate materials which may be locally available but in some places it may be economical to substitute those natural aggregates by more cheaply and abundantly available materials. Several comprehensive studies over the years have dealt with the subject of aggregate supplies and needs and the possible use of waste materials as aggregates for concrete. Attempts have been made therefore to replace natural aggregates in conventional concrete by locally available materials such as sintered domestic refuse [1], palm kernel shell [2], palletized blast furnace slag [3] and most widely recycled concrete [4-10]. Nevertheless, critical shortage of natural aggregate for production of concrete is still developing in many regions and the need for better methods of solid waste disposal and probably energy conservation have contributed to the increased interest in this technology.

In most third world countries where technological development is still growing, some regions especially large urban areas already have a problem in obtaining adequate aggregate supplies at reasonable cost. At the same time, increasing quantities of demolished asphalt pavement materials from road reconstruction projects are generated as a waste material close to these areas. These waste asphalt pavement materials are usually plowed back as sub-base material during the reconstruction process or used as embankment fill material which does not represent the most suitable use for the RAP. One of the possible ways to enhance the ample use of RAP would be to incorporate the material into Portland cement. However, little research has been done [11, 12] to explore the potential of incorporating RAP into concrete.

This paper is a discussion of the results of tests carried out to assess the performance of RAP as coarse aggregate in concrete. The performance in concrete of RAP was compared with that of uncrushed natural gravel aggregate.

Materials and Procedures

Materials

Commercially available Type I Portland cement (Dangote brand) conforming to BS 12 [13] was used in this study and the specific gravity of the cement was 3.14. The fine aggregate used in all the tests was river sand. The grading of the sand conformed to the zone 3 requirements of BS 882 [14]. The natural coarse aggregate used in the investigation is uncrushed natural gravel. The physical properties of the coarse aggregate are shown in Table 1. The tests were carried out in accordance with BS 812 [15].

Preparation and Physical Properties of RAP Aggregate

RAP coarse aggregate was prepared by crushing waste asphalt pavement rubbles obtained from a waste dump at a road reconstruction site along Enugu-Onitsha expressway, Nigeria. The old asphalt pavement was a fine-graded, hot-mix asphaltic concrete. The waste asphalt pavement rubbles were crushed, sieved and graded to sizes similar to that of the natural gravel. The RAP coarse aggregate consist therefore of “asphalt-mortar” (asphalt binder-sand-filler matrix) coated aggregates retained on 4.75 mm sieve. The physical properties of RAP aggregate are shown in Table 1. The tests were carried out in accordance with BS 812 [15].

Preparation of Specimens

Two mix proportions of 1:2:4 and 1:3:6 by weight of cement, sand and RAP aggregate were made with water/cement ratios of 0.50, 0.60 and 0.70. In addition, control mixes were made with natural aggregate having identical proportion by weight of cement, sand, coarse aggregate and water/cement ratio as their respective mixes containing RAP.

Workability test was carried out on the various concretes by slump test in accordance with BS 1881 [16] standard test methods.

All test specimens were kept under cover with wet jute bags in the laboratory until demolding at 24 hours after which they were transferred to curing water at room temperature. The properties of the hardened concrete tested were the compressive strength on 100 mm cubes and the flexural strength on 100 mm × 100 mm × 500 mm beams with third-point loading, three samples being tested at each age of 7, 14, 28, 56 and 91 days.

Results and Discussions

Aggregate

It can be seen from the results shown in Table 1 that compared to the natural aggregate, RAP has lower specific gravity and lower water absorption. The lower specific gravity of RAP may be attributed to the considerable amounts of low density asphalt-mortar (asphalt binder-sand-filler matrix) coatings on the recycled aggregate which reduced the overall density of the material (RAP). The slightly lower water absorption of RAP may also be attributed to the asphalt coating which prevented full absorption of water by the aggregate.

Table 1. Physical Properties of Coarse Aggregates

|

Physical properties |

Aggregate |

|

|

Gravel |

RAP |

|

|

Specific gravity Water absorption, (%) Aggregate crushing value, (%) Aggregate impact value, (%) |

2.70 3.2 20.1 8.2 |

2.28 2.9 - 4.3 |

|

Grading (% by weight passing sieve stated) |

||

|

25.4 mm 20.0 mm 12.5 mm 9.6 mm 4.75 mm 2.36 mm |

100 98 88 57 1 0 |

100 98 85 58 0 0 |

The aggregate crushing value test performed on RAP gave no measurable result as the test specimen under loading, rather than fragmenting tend to compress into a single dense mass. The reason could be probably due to the presence of soft asphalt binder which under the confined pressure tend to flow round the individual aggregates and thus binding the compressed and probably crushed aggregate into a single solid mass. It is then evident from the result that the crushing value test prescribed in BS 812 [15] cannot be used to assess the physical strength of RAP aggregate, a more appropriate testing method is necessary.

The aggregate impact value test result shown in Table 1 indicates a superior value for RAP compared to the natural gravel. It would be wrong however, to assume on the basis of the result that the physical strength of RAP is higher than that of the natural gravel. Rather the test result may be a probable indication that RAP is a less brittle material and can absorb more impact load than the natural aggregate. The higher impact resistance of RAP may be attributed to the presence of softer and more elastic asphalt-mortar (asphalt binder-sand-filler matrix) coatings on the recycled aggregate which probably inhibited crack propagation through the material. Thus, the developing crack rather than go through the aggregate is spread over the more elastic asphalt-mortar, during which more energy is absorbed. This may likely be the reason for the toughness improvement of concrete made with RAP [12].

Workability

The results of slump test for all concrete mixes are presented in Table 2. The results indicate that RAP concrete is less workable than natural aggregate concrete for the same free water/cement ratio. The lower workability of RAP concrete may be attributed to the high viscosity of asphalt-mortar coating on the aggregate. It is also believed that the lower workability of RAP concrete may be as a result of the rather rough irregular shape of the aggregate, the gravel aggregate having more rounded shape. Nevertheless, RAP concrete was very workable and could easily be mixed and compacted.

Table 2. Workability Test Results

|

Mix proportion |

Water/cement ratio |

Slump, (mm) |

|

|

Gravel |

RAP |

||

|

1:2:4 1:2:4 1:2:4 1:3:6 1:3:6 1:3:6 |

0.50 0.60 0.70 0.50 0.60 0.70 |

70 84 100 41 50 80 |

33 45 74 17 30 40 |

Compressive Strength

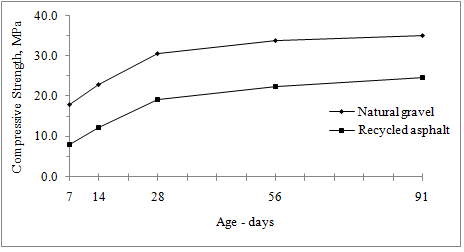

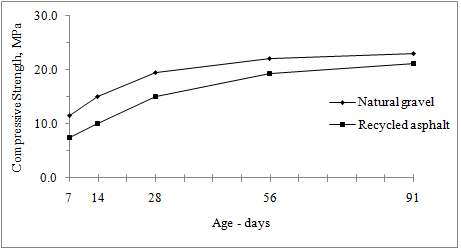

From the results of the development of compressive strength up to the age of 91 days presented in Figure 1 and 2 for all mixes, it is evident that in every case the strength continues to increase with age and that, for the given water/cement ratio and mix proportion, concretes made from the natural aggregate have a higher strength than those from RAP aggregate at all ages.

Figure 1.a. Water/cement ratio 0.50

Figure 1.b. Water/cement ratio 0.60

Figure 1.c. Water/cement ratio 0.70

Figure 1. Relationship between compressive strength and age (mix 1:2:4)

A closer examination of Figure 1 reveals that the strength of RAP concrete remained almost unaltered despite the reduction of the water/cement ratio suggesting that no further improvement in strength above 24.6 MPa may be achieved by reducing the water/cement ratio below 0.50. This trend may be explained by arguing that the strength of these concretes is governed primarily by the strength of the RAP aggregate which in turn is dependent to a large extent on the bond strength of the asphalt-mortar (asphalt binder-sand-filler matrix) attached to the aggregate particles. Failure in compression is probably initiated by the apparent weak bond between the asphalt-mortar and aggregate. This fact was established by an examination of the failure surface of the broken cubes. With the concretes made from RAP aggregate, failure in compression was dominated by a breakdown in bond between the aggregates and the attached old asphalt-mortar without any apparent crushing of the aggregate while for the natural aggregate concretes of similar mixes crushing of aggregate was more prominent. The strength of the control concrete made from the natural aggregate at water/cement ratio of 0.50 was on average of 11 MPa higher than that made from RAP at all ages. The difference in strength is however, observed to decrease as the water/cement ratio increases and was on average of 4.5 MPa at water/cement ratio of 0.70. The reason for this is that the strength of the control mix alone has been reduced due to the increased water/cement ratio with the subsequent reduction in cement mortar and bond strengths.

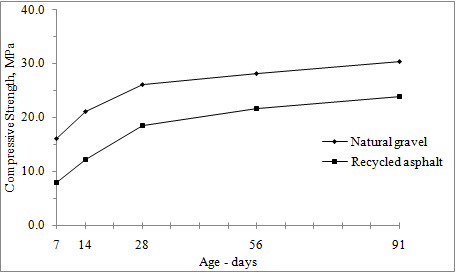

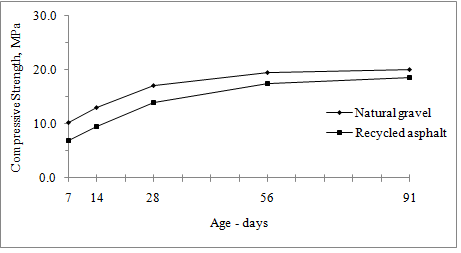

The performance of the two types of concrete is also compared in Figure 2 but the concretes in this case have been made leaner with significantly higher aggregate/cement ratio (1:3:6 by weight of cement, sand and coarse aggregate).

Figure 2.a. Water/cement ratio 0.50

Figure 2.b. Water/cement ratio 0.60

Figure 2.c. Water/cement ratio 0.70

Figure 2. Relationship between compressive strength and age (mix 1:3:6)

An examination of Figure 2 shows that, unlike the previous case of the richer mix, both concretes show a reduction in strength with increase in water/cement ratio, the natural aggregate concrete exhibiting the greater reduction. It is evident then, that with such a lean mix, the strength of the cement mortar has been reduced below that of the asphalt-mortar/aggregate bond. Compressive strength of RAP concrete is now dependent more on the strength of the cement mortar rather than on the strength of the aggregate just as with the control mix. Hence, the difference between the two becomes considerably reduced as the water/cement ratio increases and is on average of 4.2 MPa and 1.5 MPa for water/cement ratio of 0.50 and 0.70 respectively.

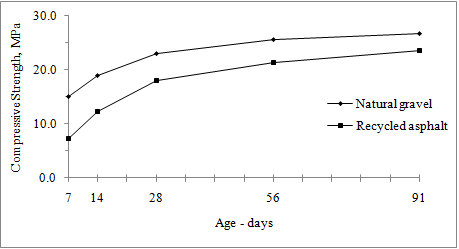

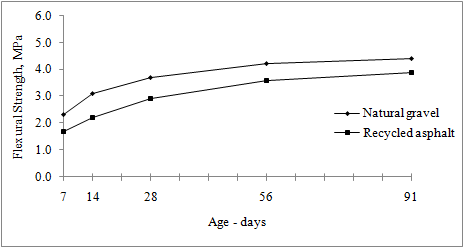

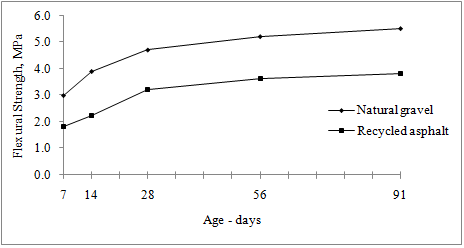

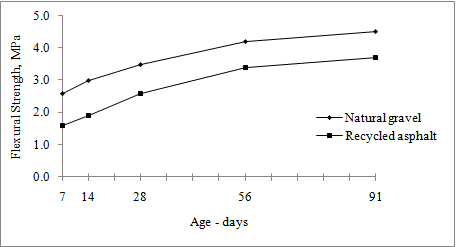

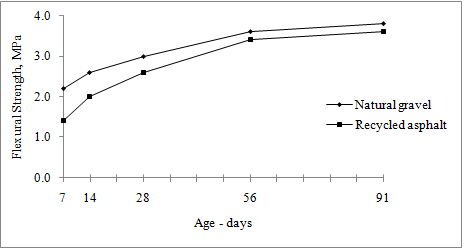

Flexural Strength

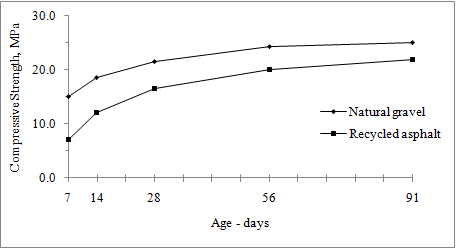

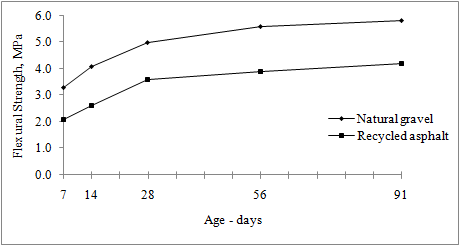

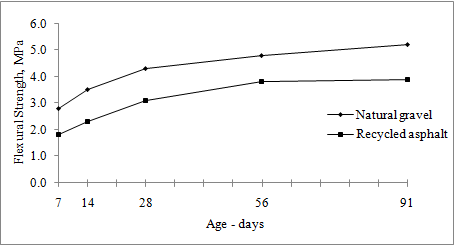

Results of the development of flexural strength up to the age of 91 days for all mixes are shown in Figure 3 and 4. The trends of the data are very similar to those of the compressive strength.

As with the compressive strength, Figure 3 indicates that flexural strength is dependent more on the bond strength of the asphalt-mortar attached to the aggregate particles. The increase in water/cement ratio of the mix from 0.50 to 0.70 had very marginal effect on the flexural strength of RAP concrete since, the flexural strength of these mixes is dependent on the bond strength of the asphalt-mortar attached to the aggregate which remain unchanged. In Fig. 4 the concrete is made leaner by increasing the aggregate/cement ratio and the bond strength of the asphalt-mortar becomes less dominant in the over-all failure mechanism, failure is now governed more by the strength of the cement mortar-aggregate bond, as with the control mix and hence their strengths are more closer together with increase in water/cement ratio.

Figure 3.a. Water/cement ratio 0.50

Figure 3.b. Water/cement ratio 0.60

Figure 3.c. Water/cement ratio 0.70

Figure 3. Relationship between flexural strength and age (mix 1:2:4)

Figure 4.a. Water/cement ratio 0.50

Figure 4.b. Water/cement ratio 0.60

Figure 4.c. Water/cement ratio 0.70

Figure 4. Relationship between flexural strength and age (mix 1:3:6)

Conclusions

From the laboratory study carried out to evaluate the performance of recycled asphalt pavement as coarse aggregate in concrete, the following main conclusions can be drawn:

1. RAP aggregate has lower specific gravity and water absorption than the natural aggregate.

2. The crushing and impact value tests as prescribed in BS 812 for assessing the strength of aggregate should not be used in assessing the strength of RAP, a more appropriate assessment method is required.

3. RAP concrete is less workable than the corresponding concrete produced with natural gravel aggregate.

4. The compressive and flexural strength of concrete produced with RAP as coarse aggregate were found to be lower than those made from natural aggregate.

5. The strength of RAP concrete is dependent on the bond strength of the asphalt-mortar coating on the aggregate

6. The maximum compressive strength of concrete that can be produced using RAP as coarse aggregate is approximately 25 MPa.

7. On the basis of this investigation, it is apparent that recycling of waste asphalt pavement for concrete aggregate is feasible and may become a viable and routine process for the generation of aggregate for middle and low strength concrete.

References

1. Wainwright P.J., Boni S.K., Some properties of concrete containing sintered domestic refuse as a coarse aggregate, Magazine of Concrete Research, 1983, 35(123), p. 75-85.

2. Okafor F.O., Palm Kernel Shell as a Lightweight Aggregate for Concrete, Cement and Concrete Research, 1988, 18(6), p. 901-910.

3. Mayfield B., Leuli N., Properties of Palletized Blast Furnace Slag Concrete, Concrete Research, 1990, 42(15), p. 29-36.

4. Ravindrarajah R., Loo Y.H., Tam C.T., Recycled Concrete as Fine and Coarse Aggregate in Concrete, Concrete Research, 1987, 39(141), p. 214-220.

5. Ryu J.S., An Experimental Study on the Effect of Recycled Aggregate on Concrete Properties, Magazine of Concrete Research, 2002, 54(1), p. 7-12.

6. Evangelista L., de Brito J., Mechanical Behaviour of Concrete Made with Fine Recycled Concrete Aggregates, Cement and Concrete Composites, 2007, 29(5), p. 397-401.

7. Tam V.W.Y; Wang K., Tam C.M., Ways to Facilitate the use of Recycled Aggregate Concrete, Proceedings of the ICE – Waste and Resource Management, 2007, 160(3), p. 125-129.

8. Kou S.C., Poon C.S., Mechanical Properties of 5-years-old Concrete prepared with Recycled Aggregate Obtained from Three Different Sources, Magazine of Concrete Research, 2008, 60(1), p. 57-64.

9. Ann K.Y.; Moon H.Y.; Kim Y.B., Ryou J., Durability of Recycled Aggregate Concrete using Pozzolanic Materials, Waste Management, 2008, 28(6), p. 993-999.

10. Kou S.C., Poon C. S., Properties of Self-compacting Concrete Prepared with Coarse and Fine Recycled Concrete Aggregate, Cement and Concrete Composites, 2009, 31(9), p. 622-627.

11. Li G., Zhao Y., Pang S.S., Huang W., Experimental Study of Cement-asphalt Emulsion Composite, Cement and Concrete Research, 1998, 28(5), p. 635-641.

12. Huang B., Shu X., Li G., Laboratory investigation of Portland Cement Concrete Containing Recycled Asphalt Pavements, Cement and Concrete Research, 2005, 35(10), p. 2008-2013.

13. BS 12: Specification for Portland Cement”, British Standard Institution, London, 1996.

14. BS 882: Part 2, Specification for Aggregate from Natural Sources for Concrete, British Standard Institution, London, 1983.

15. BS 812: Parts 1, 2 and 3, Methods of Sampling and Testing Mineral Aggregate, Sand and Fillers, British Standard Institution, London, 1975.

16. BS 1881: Part 102, Methods for Determination of Slump”, British Standard Institution, London, 1983.