Evaluation of Changes in Index Properties of Lateritic Soil Stabilized with Fly Ash

Agapitus AMADI

Department of Civil Engineering, Federal University of Technology, P. M. B. 65, Minna, Nigeria

Email: agapitusahamefule4@yahoo.com

Received: 12 October 2009 / Accepted: 10 December 2010 / Published : 24 December 2010

Abstract

For soils to be suitable in civil engineering projects, they must meet existing local requirements for index properties in addition to certain strength criteria. Typically, specifications limit these properties to some threshold values which in most cases are project specific. Some lateritic soils in their natural state need some treatment/modification to meet these specification requirements. The objective of this study was to evaluate changes in the index properties (i.e., particle size distribution, Atterberg limits and compaction characteristics) of a residually derived lateritic soil following fly ash application. Lateritic soil – fly ash mixtures with up to 20% fly ash by dry weight of soil were tested and specimens for compaction characteristics were prepared at different compaction states (optimum, dry and wet of optimum moisture content) and compacted using British Standard Light (BSL) compactive effort. While soil – fly ash mixtures containing up to 15% fly ash classify as CL according to USCS classification system and plotted above A-line in the plasticity chart, it was observed that changes in the gradation characteristics of soil sample treated with 20% fly ash resulted in the alteration of its classification to ML as well as the crossing of the A- line to the silty region. The liquid limit (LL) varied from 42.2 to 29.53% representing 70% reduction while the plasticity index (PI) of specimen treated with 20% fly ash was 16% lower than that of natural soil. The optimum moisture content (OMC) ranged from 17.36% for the natural soil to 18.34% for soil mixtures containing 20% fly ash which yielded dry unit weight of 17.2kN/m3 for the natural soil and 16.1kN/m3 for samples treated with 20% fly ash. From the study, useful data were obtained showing substantial and desirable changes in the properties of lateritic soil as a civil engineering material on application of fly ash.

Keywords

Fly ash; Index properties; Lateritic soil; Plasticity; Stabilization

Introduction

Lateritic soils are widely used as fill materials for various construction works in most tropical countries. These soils are weathered under conditions of high temperatures and humidity with well-defined alternating wet and dry seasons resulting in poor engineering properties such as high plasticity, poor workability, low strength, high permeability, tendency to retain moisture and high natural moisture content [1-3]. The effective use of these soils is therefore often hindered by difficulty in handling particularly under moist and wet conditions typical of tropical regions and can only be utilized after modification/stabilization. Lateritic soils that present such problems during construction processes are termed problematic laterites [4, 5].

The modification/stabilization of engineering properties of soils is recognized by engineers as an important process of improving the performance of problematic soils and makes marginal soils perform better as a civil engineering material. The application of chemicals such as ordinary Portland cement, lime, fly ash etc. or a combination of these often results in the transformation of the soil index properties which may involve the cementation of the particles. Previously, the most commonly used additive for soil modification or stabilization is the ordinary Portland cement. But recent studies have shown that many of the soil problems can be ameliorated by the addition of pozzolanic fly ash [6, 7].

Fly ash is a by-product of coal combustion process usually associated with electric power plants. The immediate effect of the introduction of fly ash to the soil much like a Portland cement is to cause flocculation and agglomeration of the clay particles due to ion exchange at the surface of the soil particles. The resultant effect of these reactions is to enhance workability and provide an immediate reduction in swell, shrinkage and plasticity [7-12]. The use of this material for modification/stabilization therefore offers the potential for improving performance and lowering costs of constructing some classes of low-volume roads, while at the same time utilizing an industrial by-product which might otherwise require costly transportation for disposal.

Experience with soils in the temperate zones revealed that compositional factors namely grain size distribution and plasticity characteristics exert significant influence on the engineering properties of soils [13]. Apart from assisting in the identification and classification of soils, they are indicators of problems in the fundamental properties of the soil such as compressibility, strength, permeability, swell potential and workability.

Consequently, great importance is accorded to these properties when lateritic soil is been considered for a project [14]. In this regard, they are used to screen materials for various construction purposes. For example, percentage fines ≥ 30, percentage clay ≥ 15, liquid limit ≥ 20, plasticity index ≥ 7, is specified for liner and cover materials to be used in waste landfills [15], while for road bases, materials with percentage passing BS 200 sieve > 35%, liquid limit > 35% and plasticity index > 12% are rejected without further investigation because such values give indication of poor and undesirable soil qualities for such purposes [16].

On the basis of this, mixtures of lateritic soil and fly ash with varying proportions of fly ash were subjected to relevant tests to determine changes in the index properties. These tests are grain size analysis, Atterberg limits, specific gravity and compaction tests.

Materials and Method

Materials

Study Soil: The soil sample selected for this study is a reddish brown lateritic soil with inclusions of white mottles collected by disturbed sampling from a borrow pit at depths of between 1.0 and 2.0 m in Shika, Zaria (Latitude 11°15’ N and Longitude 7°45’ E) Nigeria. It belongs to the group of ferruginous tropical soils derived from igneous and metamorphic rocks.

Fly Ash: This is a power industry by-product of coal combustion process obtained from Oji River thermal station in Enugu State, Nigeria. It is a non plastic material and black in colour, an indication of high carbon content. Only fractions passing BS sieve No. 200 (75mm) was used throughout the test without additional treatment.

Testing Methods

Mechanical and hydrometer analyses were used to obtain the particle size distributions of the soil sample in accordance with standard procedures outlined in [17]. The plasticity characteristics [i.e., liquid limit (LL), plastic limit (PL), plasticity index (PI) and linear shrinkage (LS)] as well as specific gravity of the soil and the various soil-fly ash mixtures were determined in accordance with [17] procedures. For the particle size analysis, gravel was defined as particles larger than 4.75 mm (No. 4 sieve) and fines were particles smaller than 0.075 mm (No. 200 sieve) while clay contents are the percentages of soil fraction smaller than 2μm

Compaction Test

Compaction test was conducted in accordance with procedures outlined in [17]. The soil was air dried and pulverized sufficiently to run through BS sieve No. 4 (4.75 mm). Test specimens were prepared by mixing the relevant quantities of dry soil with 0, 5, 10, 15 and 20% fly ash (by dry weight of soil) at different compaction states (optimum, dry and wet of optimum moisture content) and compacted using British Standard Light (BSL) compactive effort.

Discussion

Chemical and Mineralogical Composition of Mixture Components

The oxide composition of the soil is presented in Tables 2. The predominant oxides are silica and sesquioxide of iron and aluminum constituting about 87% of the oxides present. From the result of X-ray diffraction (XRD) conducted on soil sample from this borrow source by [18] as well as [19], kaolinite was found to be the principal clay mineral with some quartz.

The primary constituents of the fly ash are presented in Table 2.

Table 1. Properties of soil mixtures

|

Properties |

Fly Ash (%) |

||||

|

0 |

5 |

10 |

15 |

20 |

|

|

Natural moisture content (%) |

5.8 |

- |

- |

- |

- |

|

Specific gravity |

2.76 |

2.66 |

2.55 |

2.49 |

2.42 |

|

Liquid limit (%) |

42.22 |

36.5 |

34.0 |

31.24 |

29.53 |

|

Plasticity index (%) |

22.22 |

15.87 |

12.06 |

7.78 |

3.54 |

|

Linear shrinkage (%) |

9.5 |

7.82 |

6.7 |

4.56 |

2.88 |

|

USCS classification |

CL |

CL |

CL |

CL |

ML |

|

pH |

6.67 |

8.14 |

8.6 |

8.8 |

9.2 |

|

Colour |

Reddish brown |

|

|

|

|

|

Dominant Clay Mineral |

|

|

|

|

|

|

BS Light Compaction |

|||||

|

Maximum Dry Unit Weight (kN/m3) |

17.02 |

16.43 |

16.41 |

15.90 |

15.40 |

|

Optimum Moisture Content (%) |

17.50 |

18.31 |

18.76 |

18.84 |

19.09 |

Table 2. Oxide composition of lateritic soil and Fly ash

|

Oxide |

Concentration (%) |

|

|

Lateritic soil* |

Fly ash |

|

|

CaO |

0.28 |

1.78 |

|

SiO2 |

35.60 |

46.02 |

|

Al2O3 |

27.40 |

24.16 |

|

Fe2O3 |

24.0 |

13.68 |

|

MgO |

0.22 |

1.91 |

|

SO3 |

0.85 |

ND |

|

MnO2 |

2.00 |

0.56 |

|

Na2O |

ND |

5.31 |

|

K2O |

ND |

5.58 |

|

Loss on ignition |

146.00 |

1.3 |

|

*Adapted from [19]; ND – Not determined |

||

Particle Size Analysis

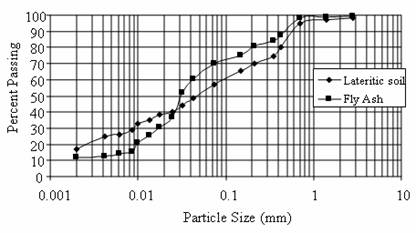

The particle size data for fly ash are presented in particle size distribution curves together with that of the lateritic soil (see Figure 1). The particle size distribution curve show that the soil contains appreciable amounts of clay-size mineral.

Texturally, lateritic soils are very variable with silt and clay contents ranging from 12% [20] to over 82% [21]. The addition of fly ash improved the gradation characteristics of the lateritic soil by reducing the amount of clay size particles. The aggregation or clusters of clay-minerals and clay-size mineral fragments due to ion exchange at the surface of the soil particles resulted in more stable silt-sand like structures. With increasing percentage of fly ash, the soil becomes more granular in nature.

Figure 1. Particle Size Distribution Curve for Lateritic Soil and Fly Ash

Atterberg Limits Variations

Atterberg limits are particularly useful indices often used directly in specifications for controlling soils for use in engineered fills. While the LL is a measure of the water content at which the soil behaves practically like a liquid, but has a small shear strength, the PI indicates the magnitude of water content range over which the soil remains plastic. In general terms, the higher the plasticity index, the higher the potential to shrink as the soil undergoes moisture content fluctuations.

The test results generally indicate that the natural soil was progressively losing its plasticity with increased amount of fly ash due to cation exchange reaction that resulted in increased interparticle attraction. For the natural soil sample, consistency test established the LL as 42.2% while for the soil mixtures; the LL was as 36.5, 34.0, 31.24 and 29.53% for 5, 10, 15, and 20% fly ash content respectively. However, increases in the plastic limit were consistently large enough to reduce the plasticity index. Hence the resulting PI decreased steadily with higher fly ash content from 22.22 for 0% fly ash content to 15.87, 12.06, 7.78 and 3.54 for soil mixtures containing 5, 10, 15 and 20% fly ash respectively. Generally, the reduction in Atterberg limits of treated soil samples were small compared to that due to lime [4, 19]. This may be attributed to low calcium ion concentration in fly ash sample used in this study.

Soil mixtures containing 0-15% fly ash were classified as CL according to USCS classification system and plotted above A-line in the plasticity chart. It was observed that changes in the Atterberg limits together with the grading characteristics of samples treated with 20% fly ash resulted in alteration of the USCS classification to ML as well as the crossing of the A-line to the silty region.

Another Atterberg limit widely linked with many plasticity based soil behaviour, the linear shrinkage, showed remarkable reduction with increase in fly ash content. Linear shrinkage decreased with increasing fly ash content from 9.5% at 0% fly ash content to 2.9% at 20% fly ash content. Variations in the Atterberg limits of the natural soil and the mixtures containing varying percentages of fly ash are reported in Table 1 as well as in Figure 2.

Figure 2. Variation of Liquid Limit, Plasticity Index and Linear Shrinkage with Fly Ash Content

Specific Gravity

As indicated in Table 1, the specific gravity of the study soil is 2.76 which is within the range of 2.6 and 3.4 reported by [13, 22] for lateritic soils. The incorporation of fly ash with specific gravity of 2.06 resulted in mixtures with lower specific gravity i.e. 2.66, 2.55, 2.49, 2.42 respectively for 5, 10, 15, and 20% fly ash contents. The generally low specific gravity of fly ash which resulted in reduced unit weight of lateritic soil - fly ash mixtures as compared to the soil alone is an attractive property for its use in geotechnical applications.

Soil pH

The pH of the natural soil is slightly acidic to nearly neutral (i.e. 6.7). The addition of fly ash to the soil raised marginally the pH of the soil – fly ash mixtures, generally increasing with fly ash content. The pH of the mixtures varied from 6.67 at 0% fly ash content to 9.2 at 20% fly ash (see Table 1). The increase in pH level observed in specimens containing fly ash may be due to hydroxides which were created by the dissolution of oxides in the fly ash.

In some geotechnical applications such as liners in waste containment facilities, good correlation exists between pH and performance of the geotechnical component. In such cases, increase in pH as in fly ash treated soils will create the required conditions for optimal performance [23].

Compaction Characteristics

The relationship between moulding water content and dry unit weight for the various soil-fly ash mixtures is shown in Figure 3. Dry unit weights were generally lower after the addition of fly ash. The maximum dry unit weight of soil mixtures expectedly decreased with higher fly ash contents while optimum water content increased as the amount of fly ash in the mixture increased from 0 to 20%. The decrease in dry unit weight with increasing fly ash content is expected because the addition of fly ash with specific gravity of 2.06 resulted in mixtures with lower specific gravity which invariably resulted in reduced dry unit weight. On the other hand, the increase in OMC with higher fly ash content could be as a result of the extra water required for the hydration of the fly ash to take place. The variations of maximum dry unit weight and optimum water content with fly ash content are reported in Figure 4.

Figure 3. Dry Unit Weight-Moisture Relationship for the Various Soil-Fly Ash Mixtures

Figure 4. Variation of Maximum Dry Unit Weight and Optimum Moisture Content with Fly Ash Content

Summary and Conclusions

This study investigated changes in some physical properties of residual lateritic soil associated with fly ash treatment. Lateritic soil – fly ash mixtures containing varying proportions of fly ash (0 to 20% by dry weight of soil) were tested and soil mixtures for compaction test were prepared at moisture content ranging from dry to wet of optimum and compacted using British Standard Light (BSL) compactive effort. Test results generally indicate that the introduction of fly ash enhanced the gradation characteristics of the lateritic soil by reducing the amount of clay size particles through flocculation and agglomeration of the clay particles. Furthermore, the natural soil witnessed decrease in plasticity index (PI), decreasing from 22.22% at 0% fly ash to 3.54% on application of 20% fly ash. The maximum dry unit weight of soil mixtures expectedly decreased with higher fly ash contents while optimum water content increased as the amount of fly ash in the mixture increased from 0 to 20%.

From the foregoing, it was established that the index properties of the study soil were substantially improved and therefore fly ash offers the potential for stabilization/modification of lateritic soil for a variety of civil engineering projects.

References

1. Maigien R., Review of Research on Laterites. Natural Resources Research IV, United Nations Educational Scientific and Cultural Organization, 1966, Paris.

2. Gidigasu M.D., Laterite Soil Engineering, Elsevier Scientific Publishing Co., 1976, New York.

3. Charman J.H., Laterite in Road Pavements. Construction Industry Research and Information Association (CIRCA), 1988, Special Publication 47, Westminster, London.

4. Osula D.O.A., Lime modification of problem laterite, Engineering Geology, 1991, 30, p. 141-154.

5. Oyediran A.T., Primary cause of highway failure in south-western Nigeria and lasting solution, Technical Transactions of the Nigerian Society of Engineers, 2001, 36(3), p. 54-60.

6. Nilo C.C., Prietto P.D.M., Carraro J.A.H., Heineck K.S., Bahaviour of Compacted Soil – Fly ash – Carbide Lime Mixtures. J. Geotech. and Geoenv. Engrg., ASCE, 2001, 127(9), p. 774-782.

7. Osinubi K.J., Amadi A.A., Eberemu A.O., Shrinkage characteristics of compacted laterite soil – fly ash mixtures. NSE Technical Transaction, 2006, 41(1), p. 36-48.

8. Vesperman K.D., Edil T.B., Berthouex P.M., Permeability of fly ash and fly ash/sand mixtures’ In: Impermeable barriers for soil and rocks, Special Technical Publication, ASTM, Philadelphia, 1985, 874, p. 170-180.

9. Bowders J.J., Usmen M.A., Gidley J.S., Stabilized fly ash for use as low - permeability barrier, Geotechnical Practice for Waste Disposal, R.D. Woods, Ed., Geotechnical Special Publication, ASCE, New York, 1987, 13, p. 320-333.

10. Edil T.B.; Berthouex P.M., Vesperman K.D. Fly ash as a potential waste liner, Proc. Conf. on Geotech practice for waste disposal, Geotech. Special Publication, ASCE, New York, 1987, 13, p. 447-461.

11. Edil T.B., Sandstrom L.K., Berthoux P.M., Interaction of inorganic leachate with compacted pozzolanic fly ash, J. Geotech. Engrg., ASCE, 1992, 118(9), p. 1410-1430.

12. Nicholson P., Kasyap V., Fly ash Stabilization of Tropical Hawaiian Soils. In: Fly ash for soil Improvement `93; Sharp, D. K. (ed.) GSP No. 36, ASCE, New York, 1993, pp. 15-29.

13. BRRI/Lyon Associates, Laterites and lateritic soils and other problem soils of Africa. An engineering study for USAID. AID/csd-2164, Baltimore, Md., 1971.

14. Ola S.A., Geotechnical Properties and Behavior of some Nigerian Lateritic soils, In: Tropical Soils of Nigeria in Engineering Practice, Ed. A. Ola Balkema, Rotterdam, 1983.

15. Benson C.H., Zhai H., Wang X., Estimating hydraulic conductivity of compacted clay liners, J. Geotech Engrg ASCE, 1994, 120(2), p. 366-387.

16. Nigerian General Specification (1997) for Roads and Bridges, Federal Ministry of Works and Housing, Abuja, Nigeria, 1997.

17. BS 1377, Methods of Testing Soils for Civil Engineering Purposes, British Standard Institution, London, 1990.

18. Ola S.A., Need for Estimated Cement Requirements for Stabilizing Lateritic Soils, Journal of Transportation Engineering Discussion, ASCE, 1974, 100(2), p. 379-388.

19. Osinubi K.J., Permeability of Lime treated lateritic soil. J. Transportation Engrg., ASCE, 1998, 124(5), p. 456-469.

20. Winterkorn H.F., Chandrasekharen E.C., Laterite soils and stabilization, High. Res. Board Bull., 1951, 44; p. 10-29.

21. Clare K.E., O’Reilly M.P., Road construction over tropical red clays. Conf. on Civil Eng. Problems Overseas, Inst. Civil Eng. 1960, p. 243-256.

22. De Graft-Johnson J.W.S., Bhatia H.S., Engineering properties of lateritic soils. General Report, Spec Session on Eng. Prop. of lateritic soils, Seventh Int. Conf. Soil Mech. and Found. Eng., Mexico City, 1969, 1, p. 117-128.

23. Osinubi K.J., Amadi A.A., Attenuation of cationic contaminants in municipal solid waste leachate by fly – ash stabilized laterite, Nigerian Journal of Engineering, 2003, 11(2), 82-87.