Investigation of the use of Ishiagu Galena Concrete in E-M Radiation Sheilding

Gabriel Ndubisi EGWUONWU1*, Paul Hena BUKAR2, and Abraham AVAA1

1 Department of Science Technology, Nigeria Institute of Leather and Science Technology, Zaria, Nigeria

2 Department of Physics, Ahmadu Bello University, Zaria, Nigeria

E-mail(s): gabneche@yahoo.com, paul.hena@yahoo.com, avaab2003@yahoo.com

* Corresponding author: Phone: +2348036936068

Abstract

Galena samples, collected from Ishiagu, south-eastern Nigeria, were used to make concretes for experimental radiation shielding. The concretes were moulded into cylindrical tablets of various densities in order to ascertain their attenuation capability to some electromagnetic radiations. Blue visible light and gamma-ray (455-500 nm) sourced from cobolt-60, were transmitted through the concretes and detected with the aid of Op-Amp and digital Geiger-Muller Counter respectively. The absorption coefficients of the samples of thicknesses in the range of 1.00 mm – 5.00 cm were determined. Results obtained show that a typical Ishiagu galena concrete of about 2.80 g/cm3 has the capacity of shielding visible blue light with about 2.51 mm TVL and 0.81 mm HVL. It also shows that the concrete of similar density can optimally shield gamma radiation with about 5.06 cm TVL and 1.53 cm HVL. The results of the investigation however, suggest the shielding and engineering properties of the galena sourced from Ishiagu. A database of shielding strength for the insitu galena was established hence, can serve as suitable platform for quality and quantity control in radiation shielding technology and can be used in high voltage radiotherapy rooms and nuclear reactors.

Keywords

Galena; Radiation Shielding; Gamma Ray; Value Layer.

Introduction

Radiations namely; ionizing and non-ionizing are capable of causing harm to man and changing properties of certain materials. However, the challenge of ameliorating the problem of harmful radiation in nuclear, X-ray and other related technology, has taken a lot of effort. Hence radiation shielding is an important art applied in the use of some electromagnetic radiations and most radionuclide. The essence of the shielding is to attenuate the harmful and unwanted rays from exposure to users who work with them or close their sources [1,2]. Dense materials such as the ore of Haematic (FRO2O2), magnetite (FeO4), Anglesite (PbCO3) or Galena (PbS) can be used as aggregate of concretes meant for shielding [3].

Galena, a latin term for lead sulphide, particularly is named after Alaska which is also known as the City of Galena. It is a sulphide mineral useful in diverse ways namely; in making lead batteries, solder, TV tubes, glass, construction, communications and protective coatings, X-ray and gamma radiation shielding, ballast/weights, electronics and ammunition. Galena is a mineral of about 86.6% lead and 13.4% of Sulphur. Therefore it is one of the most widely distributed of all sulphides and constitutes the most important ore for lead [4]. The average hardness of galena is about 2.85 on mineralogy scale and it has a specific gravity in the range of 7400 -7600 kgm-3. The melting and boiling points of it are 1114ºC and boils at 1290ºC. Galena crystallizes in isometric systems usually in cubes and sometimes in octahedral form. It belongs to mesothermal (200-300ºC) deposits hence often occurs with admixture of silver, bismuth, copper, zinc and selenium in veins of various hydrothermal crystalline or sedimentary rocks. Optically, galena has a reflection coefficient of about 32.2% of white light. Electrically, it is apparently an excellent intrinsic semi-conductor with energy gap of about 0.4 eV having a conductivity of about 2×10-3 Siemens and optimally photoconductive between 10,000 A and 30, 000A. Galena slows photoelectric effect that is sometimes positive and sometimes negative [5].

In Nigeria, it can be found naturally in commercial quantities in Benue Valley which is almost parallel to River Benue, spreading across Ishiagu and Abakaliki in Ebonyi State, Gboko and Makurdi in Benue State, Arufe, Wukari in Taraba State, Awe Ibi and Filiya area in Borno State. Ishiagu is Ishiagu District of Ebonyi State south-eastern Nigeria. The town is bounded by longitudes 7°29’–7°35’E and latitudes 5°43’-5°51’N. The relief of Ishiagu mining site is low-lying and undulating. The rocks are extensively fractured, folded and faulted. The mineralization of the site occurs as series of closely spaced, steeply dipping sub-parallel fractures which trend NW-SE. It is exclusively fissure-filling and distinctively patterned in the NW-SE fractures and gangue minerals [6]. The site comprises sand, lenses of sandstone and limestone, shale’s with fine grained micaceous sandstones and mudstones that are Albian in age.

Galena which often occurs as fine granular aggregates and sphalerite are the dominant constituents of the veins [6]. The distribution of Pb, Zn, and other heavy elements in Ishiagu is due to their occurrence in veins and veinlets. Galena occurs in mineralized vein, mine dumps, folded shales, the Asu River Shales and the minor basic intrusive [7].

Ishiagu is endowed with some mineral ore deposits namely galena (PbS) which serves as major source of lead and sulphides in the area, sphalerite (ZnS), chalcopyrite (CuFeS2), siderite (FeCO3), argentite (AgS) limestone (CaCO3) and cadmium sulphide (CdS) [6,8]. Galena obtained from Ishiagu locality is selected for study due to its satisfactory mechanical property, availability, accessibility and relatively affordable cost. Galena concrete is an aggregate bound together with other constituents namely sand, cement and water. It is made to obtain various densities or thicknesses which will give satisfactory shielding properties to radiation of high penetrating power. The concrete shielding properties may vary depending on the composite of the concrete [9]. This investigation is therefore targeted on providing both the quantitative and qualitative capacities of various densities and thicknesses of concrete [10] of the galena sourced from the Ishiagu galena deposit. It is also is aimed at establishing a database for the use of the Ishiagu deposit as a shielding material against radiation. The investigation is expected to provide results which should aid decision-making on the design and layout of shielding blocks casts in reactor shielding wall [11]. Hence the investigation will invariably offer both technical and economic advantages to shielding technology.

This research is therefore aimed at ascertaining the extent to which the Ishiagu Galena concrete could attenuate visible blue light and gamma radiation.

Material and Method

When electromagnetic radiation passes through matter, photoelectric effect, Compton scattering and pair production interactions usually occur [12]. The predominant interaction depends on the density of the material and the radiation intensity. After the interaction, the intensity of the radiation reduces due to absorption [13]. The degree of interaction between the radiation and the charges contained in the material is dependent on whether the charges are tightly bound as the inner shell electrons of lattice ions or of the lattice ions themselves, loosely bound as the outer shell electron of lattice ions or free electrons as are the conduction electrons in a metal or semiconductor. For certain wavelength of radiation, the diminution of intensity depends exponentially on both the length of the optical path in the absorber and the absorption coefficient which is a constant for a given substance. Therefore for a material of thickness “t” the intensity of the radiation “I” after traversing through the material is given as:

|

I=Ioe-ìt |

(1) |

where Io is the initial intensity, ì is the attenuation coefficient. The decrease in the intensity dI of the beam of initial intensity I0 when in transverse through a small thickness dt of the material is:

|

dI= -ìdt |

(2) |

Such that:

|

|

(3) |

Hence:

|

|

(4) |

Therefore:

|

|

(5) |

When constituents are added to galena, they act as impurities. The impurity amount changes the intrinsic property of the galena. The change in intrinsic property results to either or increase or decrease in the energy gap which eventually increases or decreases the conductivity and absorptive property of the concretes [14]. This is the basis for serve as the basis for the evaluation of the shielding property of galena concrete by the estimation of its absorption coefficient [15].

The relation for the absorption coefficient ì which measures quantitatively, the properties of the various radiation concrete shields can be expressed as:

|

|

(6) |

or:

|

|

(7) |

where Vo and No are the voltages or number of counts measured before traversing a material medium of thickness “t” whereas Vt and N0 are the voltages or number of counts measured after the same depending on what kind of irradiation is measured: electrical or nuclear. Also, the thickness of the shield which reduces the radiation to one-tenth of incident energy on it known as the tenth-value layer (T.V.L) for any materials is given by:

|

|

(8) |

While, the Samples of galena were collected from manually excavated deposits by local miners and from existing Ishiagu mining companies. Galena thickness of the shield which reduces the radiation to one-half of that incident on it, known as the one-Half Value Layer (HVL) of the shield is given as:

|

|

(9) |

It is commonly required in nuclear technology that the shielding capacity of materials in terms of the thickness of it which reduces the radiation to one-tenth (T.V.L.) or half (H.V.L.) of its value of its incident intensity is evaluated.

Portland cement, sand, water, measuring cylinder, weighing balance, grinding machine, plastic moulds, moulding machine, hand trowel, pestle and mortar were used in the making of galena concrete. The introduction of the other constituents to the aggregate (doping) was to make the galena extrinsic from it intrinsic nature. Lumps of galena were finely ground and sieved with a 0.4 mm sieve. The sand was sieved with a 2.0 mm sieve and the aggregate galena, sand and cement were weighed separately and thoroughly mixed. Water was measured in a measuring cylinder, weighed, added to the aggregate, thorough mixing of the aggregate was further carried out and finally, the concrete was poured into the plastic mould and the precast was left to set for five days at room temperature. Six sets of various thicknesses of the concrete of the same diameter were moulded. Secondly, six sets of the concrete were prepared using constituents of various densities. Table 1 shows the constituents of the aggregate concretes for the six sets of the samples.

Table 1. Constituents of the Various Sets of the Galena Concretes Samples

(Standard deviation in density = 0.01)

|

Sample ID |

Galena (g) |

Portland Cement (g) |

Sand (g) |

Distilled water (g) |

Density (g/cm3) |

|

X |

150.00 |

11.00 |

15.00 |

15.00 |

3.51 |

|

A |

164.00 |

40.00 |

28.00 |

13.00 |

2.33 |

|

B |

87.00 |

50.00 |

25.00 |

30.00 |

2.28 |

|

C |

69.00 |

57.00 |

30.00 |

19.00 |

2.08 |

|

D |

60.00 |

70.00 |

25.00 |

23.00 |

2.15 |

|

Y |

12.00 |

82.00 |

20.00 |

10.00 |

3.15 |

|

Source: Field Work |

|||||

The constituents added to galena were meant to act as impurities which varies in concentration in the various samples prepared hence changing the intrinsic property of the galena. The changes in the intrinsic property cause an increase or decrease in the energy gap which will either increase or decrease and absorption of the material. These effects serve as the basis for the evaluation of the shielding property of galena concrete on the measurement of the absorption of various samples of galena concrete by the estimation of their absorption coefficient.

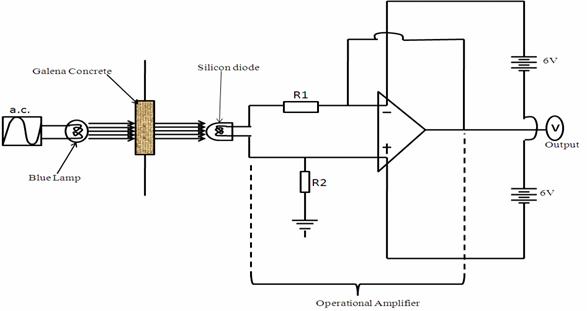

Two methods were used in the investigation of the shielding properties of galena concrete namely; electrical and nuclear methods. In the electrical method, two power sources were adjusted to about 6 Volts with the aid of a voltmeter. The pair of power supply was connected in series with the operational amplifier [16], (figure 1).

Figure 1. Schematic set up of the investigation using the Operational Amplifier

(Source: Laboratory Experimental Design)

The input of the operational amplifier was connected to the negative terminal of silicon diode, the output to the voltmeter whereas all the negative terminals earthed. The average output voltage was taken before the samples were positioned for irradiation. The circuit was closed and the light source was on. Deflection occurred on the voltmeter for little change and was recorded. The average voltage change between the closure and opening of the circuit “Vo” which corresponding to the intensity of the blue light source was recorded. While the system was shielded from environmental light in order to drastically minimize error, several measurements were taken and the average voltage of (V0 = 1.0 V) for the blue light’s intensity I0 were recorded. Secondly, the shielding properties of galena concrete of various densities ranging from 2.08 gcm-3 to 3.51 gcm-3 and various thicknesses, ranging from 1.00 mm to 5.00 mm, at interval of 1.00 mm, were tested by the irradiation of the samples of the concretes using the blue lamp. The deflection on the voltmeter due to the intensity of the light received by the silicon diode after the radiation has traversed through the material, were recorded. Each datum collection was repeated as much as possible in order to minimize error.

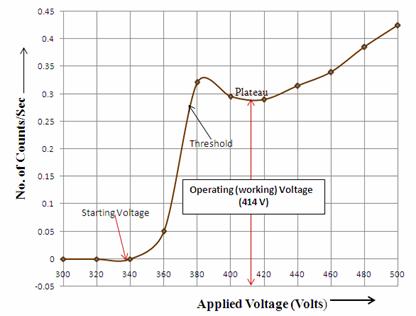

In nuclear method of the experiment, the voltage characteristics and the background count of Geiger counter were first of all determined so as to adequately estimate of the best operating voltage of it. Secondly, the emission rate of cobalt-60 was determined and finally the effect of the galena concrete on the emitted radiation traversing it was investigated. After warming the digital Counter for about 3 minutes, the voltage was adjusted gradually from 300 V with an increment interval of 20 V to 500 V. It was noticed that the Counter commenced counts from 360 V hence; the average number of counts per 10 seconds was recorded. The counts gradually increased with increasing voltages, at a particular range and later remained almost constant (between 390 and 438 Volts). Afterwards, it resumed the increase in counts with increase in voltage again. The mid value of that range (414 Volts) at which the counts almost remain constant was considered as the best operating voltage of the Geiger counter and was used to determine the background count (figure 2). The numbers of pulses counted per 20 seconds were recorded and this was repeated fifty times. The cumulative average of the number of counts per the fiftieth time (1000 seconds) was estimated to be 0.348 counts/sec as the background count of the Geiger counter.

Figure 2. The Characteristics of the Geiger Counter showing its Best Operating Voltage

Afterward, cobalt-60 was placed and exposed to enter the Geiger-Muller tube directly without any concrete as a shield. The effective number of counts per 20 seconds was taken and 50 counts of the exactly the same duration and this was estimated to be 3.484 counts/sec. Finally, each of the concrete shields of various densities ranging from 2.08gcm-3 to 3.51 gcm-3 and various thicknesses ranging from 1.00 cm to 5.00 cm, at interval of 0.50 cm, were tested by the irradiation of the samples of the concretes using gamma rays. The shielding properties of the galena concretes were investigated as they were placed between the source and detector and irradiated by gamma flux.

Results and Discussion

Results of the two experiments were tabulated and plotted on a two-dimensional graph. From the plot of Vo/Vt against thickness of shields “t” (figure 3), each concrete shows a curve which starts from t = 1.0 mm corresponding to V0/Vt~1.75 and decreases exponentially towards the t axis with the t axis as an asymptote. Figure4 shows the plot of the logarithms of the V0/Vt against the various thicknesses “t” of the shields.

Figure 3. Plot of Vo/Vt against Thickness of Shield t

Figure 4 which shows the graph of ln Vo/Vt against thickness “t” of the shields shows straight lines having negative gradient for the various thicknesses of the concrete shields. The plot shows that the densities of the concrete shields have direct proportionality with the attenuation of the radiation intensity reaching them. Hence the gradient of each line (figure 3) equals the absorption coefficient for each set of the concrete of common density. The graph of N against thickness of the shields “t” (figure 4) shows that for each set of concrete shield of a particular density, there is a curve starting from t = 1.0 cm and N~ 0.70 which exponentially decreases with thickness and is patterned as an asymptote to t-axis.

Figure 4. Plot of ln V0/Vt against the Thickness of the Samples

The results of the Geiger counter as the concrete shields were irradiated were also tabulated and plotted. Figure 5 shows the plot of the number of counts N against the various thicknesses “t” of the samples for the various densities of the concrete shields while Figure 6 shows the plot of the logarithm of N (ln N) against the various thicknesses “t” of the samples.

Figure 5. Plot of the Numbers Counts N against thickness of Samples

The graph of ln N against thickness of shield “t” (figure 6) shows that for each concrete density, there is a straight line with negative gradient. Hence the gradients of the lines equal the absorption coefficient of each set galena concrete of common density.

Figure 6. Plot of ln N against the Samples' Thickness

Table 2 shows the summary of the results’ interpretation vis-a-vis the absorption coefficient, tenth value layer and the half value layer of the galena concrete in the two methods of the investigation.

Table 2. Summary of the Results on the Investigation of the Shielding Capacity of Ishiagu Galena Concretes

|

Samples’ ID |

Density (g/cm3) |

EM Radiation: Blue Visible Light |

EM Radiation: Gamma Ray ((455-500 nm) 1.33 MeV) |

||||

|

Absorption Coefficient (ì) |

(T.V.L.)

|

(H.V.L.)

|

Absorption Coefficient (ì) |

(T.V.L.)

|

(H.V.L.)

|

||

|

X |

3.51 |

-0.108 |

2.132037 |

0.641806 |

-0.650 |

3.542462 |

1.066385 |

|

A |

2.33 |

-0.082 |

2.808049 |

0.845305 |

-0.448 |

5.139732 |

1.54721 |

|

B |

2.28 |

-0.080 |

2.87825 |

0.866438 |

-0.350 |

6.578857 |

1.980429 |

|

C |

2.08 |

-0.070 |

3.289429 |

0.990214 |

-0.418 |

5.508612 |

1.658254 |

|

D |

2.15 |

-0.071 |

3.243099 |

0.976268 |

-0.579 |

3.976857 |

1.19715 |

|

Y |

3.15 |

-0.098 |

2.349592 |

0.707296 |

-0.505 |

4.559604 |

1.372574 |

Based on the interpreted data in Table 2, it can be observed that for the range of density 2.08-3.15 g/cm3 of the galena concrete, T.V.L. to the blue visible light ranges between 2.13 mm and 3.29 mm while H.V.L. to the same ranges between 0.64 mm and 0.99 mm. These results imply that on the average, the concrete of about 2.80 g/cm3 has the capacity of shielding visible blue light with about 2.51 mm T.V.L. and 0.81 mm H.V.L. To gamma radiation, galena concrete of similar density range has T.V.L. and H.V. L. in the ranges of 3.54 to 6.58 cm and 1.07 to 1.98 cm respectively. These results also imply that on the average, the same concrete of about 2.80 g/cm3 has the capacity of shielding gamma radiation with about 5.06 cm T.V.L. and 1.53 cm H.V.L. Hence, further observation shows that to the blue visible light, as concrete’s density decreases by -0.291 g/cm3, corresponding increment in T.V.L. and H.V.L. are at 0.243 mm and 0.073 mm respectively (figure 7). On the other hand, to gamma radiation, density decreases of the concretes at -0.291 g/cm3, corresponds to increment in H.V.L. and H.V.L. at 0.272 cm and 0.081 cm respectively (figure 8). These imply that incident intensity of EM sources can optimally be shielded, housed or stored, reacted or conveyed using a typical Ishiagu galena concrete. For instance, gamma beams which are of high intensity can be extracted to an experimental hall (HD-hall) and transported to a production target. The conveyor in form of beam line tunnel is usually required to be made of concrete shields in the HD-hall [17] hence offering advantages to shielding industry.

Figure 7. Comparative Plot of T.V.L., H.V.L. and the Density of Ishiagu Galena Concrete in the Electrical Method

Figure 8. Comparative Plot of T.V.L., H.V.L. and the Density of Ishiagu Galena Concrete in the Nuclear Method

Therefore, a typical Ishiagu galena concrete of about 2.80 g/cm3 has the capacity of shielding visible blue light with about 2.51 mm T.V.L. and 0.81 mm H.V.L. Also, with about 5.06 cm T.V.L. and 1.53 cm H.V.L., the Ishiagu galena concrete can optimally shield gamma radiation. Investigation has also confirmed that shielding strength of the concretes varies directly with their thicknesses and densities. These data invariably support and aid the design and modelling in commercial production of shielding materials particularly where galena concrete are doped. Hence results obtained in the foregoing are expected to aid decision-making on the design and layout of shielding blocks cast such as reactor shielding wall thereby have offered both technical and economic advantages to industry.

Conclusions

The shielding effect of galena concrete walls based on the foregoing investigation is sufficient for providing useful barriers to electromagnetic radiations which are capable of causing harm to living organisms, even of high penetrating power. It therefore implies that the application of galena concrete in the making of walls of conventional building materials can optimize the building E.M. shielding capacity. Therefore to radiotherapy rooms, nuclear reactors and similar houses, the estimated shielding capacity of dense materials, even though they may not provide all the shielding necessary in given walls, is of valuable importance in modern times.

References

1. Profio A.E., Radiation Shielding and Disimetry. A. Wiley- Intersaence Publication. John Willey and Sons, New York, pp. 409, 1978.

2. Cember H., Introduction to Health Physics. McGrawHill, New York, pp. 99-107, 1992.

3. Kase K.R., Nelson W.R., Fasso A., Liu J.C., Mao X., Jenkins T.M., Kleck J.H., Measurements of accelerator-produced leakage neutron and photon transmission through concrete. Health Phys, 2003, 84, pp. 180-187.

4. United Nations, Review of Scientific Information on Lead, Environment Programme, Dtie/Chemicals, 2006.

5. Mortazavi S.M.J., Mosleh-Shirazi M.A., Maheri M.R., Yousefnia H., Zolghadri S., Hajipour A., Production of an economic high-density concrete for shielding megavoltage radiotherapy rooms and nuclear reactors, Iran. J. Radiat. Res., 2007, 5(3), p. 143-146.

6. Ezepue M.C., The Geologic Setting of Lead-Zinc Deposits at Ishiagu, Southeastern Nigeria Journal of African Earth Sciences, 1984, 2(2), p. 97-101.

7. Ezeh H. N., Chukwu E., Small Scale Mining and Heavy Metals Pollution of Agricultural Soils: The case of Ishiagu Mining District, South Eastern Nigeria. Journal of Geology and Mining Research, 2011, 3(4), p. 87-104.

8. Duruibe J.O., Ogwuegbu, M.O.C., Egwurugwu J.N., Pollution profiles of non-metallic inorganic and organic pollutants of drinking and potable waters due to mining activities in Ishiagu (Ebonyi State) of Nigeria. International Journal of Physical Sciences, 2007, 2(8), p. 202-206.

9. Kharita M.H., Takeyeddin M., Al-Nassri M., Yousef S., Development of special radiation shielding concretes using natural local materials and evaluation of their shielding characteristics. Atomic Energy Commission, Damascus, Abstract of Scientific Research Journal Article, pp. 58, 2008.

10. Trout E.D., Kelley J.P., Lucas A.C., Conventional Building Materials As Protective Radiation Barriers. Radiology U.S., 2009, 76, p. 237-244.

11. Zaytsev L.N., Methods of Making Concrete Blocks for the Shielding Walls of Buildings Housing Nuclear Reactors and Accelerators. BetonI Zhelezobeton; 2009, 5, p. 227-230.

12. Greening J.F., Fundamental of Radiation Dosimetry. Page Bros, Norwich Ltd. 2nd Ed. p. 18, 1985.

13. Ghoshal S.N., Nuclear Physics, Chand S. and Sons Company Ltd. Ram Nagar, New Delhi-110 055, p.188-191, 2008.

14. Knoll G.F., Radiation Detection and Measurement. John Wiley and Sons, p. 787-788, 1979.

15. Connolly T.J., Fundamental of Nuclear Engineering, John Willey and Sons, New York, p.135, 1978.

16. Sorenson J.A., Phelps M.E., Physics in Nuclear Medicine. Willey and Sons, New York, p.75-6, 1980.

17. Hirose E., Tanaka K.H., Takahashi H., Agari K., Ieiri M., Katoh Y., Minakawa M., Noumi H., Sato Y., Suzuki Y., Takasaki M., Toyoda A., Yamanoi Y., Watanabe H., Katoh K., Saitoh N., Saijyo M., Applied Superconductivity, IEEE Transactions Phys. Div. IV, High Energy Accel. Res. Organ., Tsukuba 2008, 2, p. 1439-1442.