Casting of Motorcycle Piston from Aluminium Piston Scrap using Metallic Mould

Francis Uchenna OZIOKO*

1 Mechanical Engineering Department, Federal University of Technology, Minna, Nigeria

E-mail: uozioko@yahoo.com

* Corresponding author: Phone: +2348028854727

Abstract

The casting of motorcycle piston was carried out using metallic mould. The prepared piston sand core was positioned in the mould to provide casting with contours and cavities. The molten metal of required composition was poured into the metallic mould, allowed to solidify and take the desired shape of the cavity. Aluminium silicon piston scraps were used as the casting material. Melting of the aluminium piston scraps was achieved using local crucible furnace and finally pouring the molten metal into the metallic mould having the prepared piston sand core in place to obtain the piston. After fettling and cleaning, the casting was found to be good. The composition test revealed that the scrap piston was made from LM29 aluminium alloy. The cast piston was machined and subjected to performance rating test in a Jincheng AX100 motorcycle engine. The rating used was based on a scale from 1 to 10. The higher the rating, the better the evaluation of the piston in the specific area rated. Deposits are evaluated by appearance, ranging from 10 (clean - absence of deposits) to 0.0 (maximum deposits). In spite of various production constraints the result of the performance test was good. The rating showed that the locally cast piston compared favourably with imported piston.

Keywords

Piston; Metallic mould; Piston core; Crucible furnace; Fettling.

Introduction

Casting refers to the pouring of molten metal of required composition into a mould having the desired cavity, in which it cools and solidifies to takes the desired shape of the cavity. However, the main casting methods available include: permanent mould casting, in which liquid metal is poured into mould cavity machined with metal block; sand casting, in which liquid is poured into a shape cavity mould from sand; centrifugal and investment casting also exist. Metallic moulds have good thermal conductivity permitting rapid rate of solidification of liquid metal given rise to a cleaner, finer crystal grain size and enhanced mechanical properties higher than those from sand casting of equivalent composition. This of course makes the use of metallic mould more suitable than sand mould which has a fairly low thermal conductivity.

Metal castings alloys are vital components widely used in the automotive, aerospace and general engineering industries. Cast metals parts accounts for more than fifty percent of an automobile engine. Above all, casting offers a process of improving the mechanical properties of components or articles. In aluminium casting, the typical alloying elements are magnesium, manganese, copper, silicon, and zinc. Aluminium alloys containing major elemental additives of Mg and Si, have become potential subsititute for steel panels in automobile industries. [1] reported that aluminum has surpassed iron as the second most used automotive material worldwide (behind steel). A total of about 110 kg of aluminium vehicle in 1996 is predicted to rise to 250 or 340 kg, with or without taking body panel or structure applications into account, by 2015 [2].

Modern high performance automobiles have many individual heat exchangers, e.g. engine and transmission cooling, charge air coolers (CACs), made up of aluminium alloys [3]. The Al-Si alloys have been subject of several scientific studies in the past few years [4] and its popularity resulted in a continuing increase in their demand for components with higher and consistent mechanical properties [5].

Among commercial aluminium casting alloys, aluminium silicon are the most important ones mainly due to their excellent combination of properties such as good cast ability, good surface finish, light weight, fewer tendencies to oxidation, lending to modification, low coefficient of thermal expansion, high strength-to-weight ratio and good corrosion resistance. These properties led to their excessive use in many automobile and engineering sectors where wear, tear and seizure are the major problems in addition to the weight saving. Some of these components are cylinder heads, pistons, connecting rods and drive shafts for automobile industries and impellers, agitators, turbine blade, valves, pump inlet, vortex finder in many marine and mining sectors [6].

All cast metals, with the exception of steel, can be cast by the permanent mould method. The commonly non-ferrous alloys cast by this process are aluminium base, copper base and magnesium base alloys. The temperature of these alloys ranges from 680°C to 450°C [7]. Melting and pouring are part of quality control processes in preparing molten metal of the required composition. For a particular casting alloy, the pouring temperature is taken with a certain super heat over its liquids temperature. The super heat temperature is chosen considering its influence on the structure and mechanical properties of metal, the wall thickness of casting, the inclination of the metals to form films, the thermo-physical properties of the mould material and the initial temperature of the mould material and other factors. The pouring temperature for aluminium alloy is 680°C-700°C, for bronzes and brasses is 1000-1200°C, for magnesium alloy is 700-800°C, for steel is 1520-1620°C and fore cast iron is 1300-1450°C [8]. [9] reported that optimum pouring temperature for good quality cast aluminum alloys is between 700°C and 750°C .

Recently, sustainability and recycling of resources are of paramount importance with increasing public awareness on environmental issues, energy and depleting natural resources. Aluminium has been recycled since its first commercial production and today recycled aluminium accounts for one-third of global aluminium consumption. This work covered the casting of motorcycle piston from scrap aluminium silicon piston alloy using a metallic mould and subsequently compares performance of cast and imported piston in an AX 100 motorcycle engine.

The aim of the research was to produce locally AX 100 motorcycle piston from aluminium piston scraps and to ensure that they conform to specification required.

Material and Method

The samples of pistons were cast with the aid of metallic mould and split wooden core box shown in figure 1. Other materials are silica sand, aqueous sodium silicate, gas cylinder, spray gun, plumb ago dust, isopropyl alcohol.

|

|

|

Figure 1. Core box and Metallic Mould Tools [4] |

Piston Core Production

Pure silica sand was used. The sand was washed with sufficient water for several times, drained in a sack and dried under sun. This was to reduce the clay and salinity contents in the sand. The dried sand was sieved to remove coarse sand grains. This was to reduce metal penetration during casting and to remove other foreign bodies in the sand. A specific quantity of the sand was fetched and starch was added to the sand and mixed thoroughly with the sand for two minutes. The starch addition was to improve collapsibility and ease of knockout. Sodium silicate (aqueous) binder was added and the mixture mixed for three minutes. A total mixing time of five minutes was used.

The forming of piston core was done using split core box in figure 1. The core box cavity was rammed full of mixed core sand to form the piston core. After ramming, the core box was gassed with gas contained in cylinder and the core stripped out afterwards. A typical sand mix is shown in Table 1.

Table 1. Sand Mix Composition of Core [4]

|

Materials |

% Composition by weight of core |

Weight in 153g |

|

Silica sand |

96.5% |

147.65 |

|

Starch |

1.5% |

2.3 |

|

Sodium silicate |

2% |

3.06 |

|

Carbon (iv) oxide (C02) |

0.5% |

0.76 |

Melting Furnace

The furnace used for the melting of the aluminium scrap was crucible furnace, which makes use of coke for burning. The process involved re-melting clean scrap; therefore principal concern was to avoid melting losses and gas inclusion. Fast melting with minimum disturbance was aimed. The melting of scrap with crucible is shown in figure 2.

|

|

|

Figure 2. Melting of scrap pistons |

Piston Production

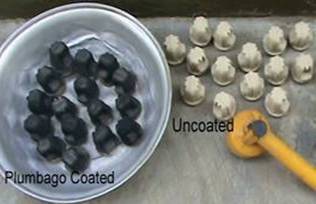

The piston production was carried out using metallic mould machine shown in figure 1. At the foundry the mould cavity was prepared via coating and preheating. The coating was done using plumb ago dust with isopropyl alcohol as the carrier uniformly applied using spray gun. The mould cavity was preheated to 200°C using oxy-acetylene flame. The preparations allowed the mould to readily accept the molten metal when poured and also help minimize the number of unacceptable casting that may be obtain during the establishment of operating temperature. After mould cavity was prepared and core placed in properly, molten metal was scooped out with a ladle from the crucible and poured into the mould through the sprue. Charging and melting was for 1.5 hours.

The piston scraps were heated 10°C above the specified pouring temperatures. This was to compensate for temperature loss during pouring of the melt. The pouring temperature was measured by a thermocouple. In the pouring ladle, the tip of the instrument was allowed to make contact with the base of the molten metal contained in it. Two temperature readings was noted and recorded accordingly. The first was the temperature reading at the beginning of pouring of the melt into the mould and the second was temperature recorded immediately the mould was filled up. The average of these two temperatures calculated was the temperature for the pouring. In other to achieve minimum composition loss; excessive stirring, overheating of the molten metal and prolonged heating were avoided. In minimizing impurity use of dried charge material, ladles tools heated by evolving furnace heat, cleaned and de-carbonized piston scraps were emphasized.

Dissolved hydrogen reduction and oxide separation was carried out by plunging tablets of hexachloroethane into the melt at 10°C above pouring temperature of 700°C. The hexachloroethane tablet added was 15.3g against charged weight of 6.12kg. The furnace environment was heated by charcoal fire around the furnace environment to drive off moisture, thereby preventing moisture dissociation near the molten metal surface.

The poured molten metal was allowed to solidify in the mould before it was removed and placed into a bin of hot water. The water was used to reduce the cooling rate and hence facilitate a more even settling of the hot cast metal. The cooled casting was removed from bin of hot water and fettling operation was conducted using the normal methods. The cast pistons were fettled, placed on a lathe and machined to standard specification of AX 100 piston. The piston after machining was subjected to surface finish and dimensional accuracy by touch, visual inspection, and vernier calliper.

Testing of the Cast Piston

The test was carried out on a stationary motorcycle having the machined piston with rings, piston pin and circlip positioned inside the combustion chamber. In achieving this test motorcycle engine was fuelled with premium unleaded gasoline. The motorcycle used was Jincheng AX100 with specifications: dimension (L*W*H) 1865x725x1050mm; wheel base 1260mm; dry weight 77kg; engine type single-cylinder, air-cooled, four-stroke; bore stroke 50mm x 49.5mm; displacement 98.0cm3; maximum power 4.5kW/rpm; final drive chain; 4-speed gear box; start electric start/kick start; max. speed 95km/h; fuel tank capacity 12L; battery,12V. In carrying out this test the piston was subjected to six hours prescribed idling, and then run under strenuous two-hours, replicating a typical operating routine.

Inspection of Piston after Test

After eight exhausting hours using cast piston, the engine was disassembled, inspected in the areas of piston ring deposit accumulation, piston ring sticking and measured for wear. The test process was also repeated using new imported piston. The rating used was based on a scale from 1 to 10. The higher the rating, the better the evaluation or performance of the piston in the specific area rated. The piston grooves was rated as to the state of wears and the degree of circumference around the piston that they were worn. Deposits are evaluated by appearance, ranging from 10 (clean- absence of deposits) to 0.0 (maximum deposits).

Spectrographic Test on Imported and Cast Piston

The chemical compositions were carried out using mass spectrometer to determine the exact alloy composition on imported piston and cast piston-specially since Mg easily volatilizes. The samples were first ground with 120 μm SiC paper and then analyzed. Five recordings were made on each sample and the values averaged.

Results and Discussion

The chemical composition comparison of the piston alloys is presented in Table 2. The chemical composition analysis was done in other to achieve an extended comparison, with a view of ascertaining if there was a substantial variation. It subsequently determines whether measures adopted to prevent inclusions and composition loss during casting achieved result.

Table 2. The Chemical Composition of the Piston Alloys

|

Elements |

Imported Piston [%] |

Cast Piston [%] |

Variation [%] |

|

Si |

22.86 |

22.29 |

-2.5 |

|

Fe |

0.413 |

0.427 |

+3.3 |

|

Cu |

0.80 |

0.774 |

-3.2 |

|

Mg |

0.60 |

0.57 |

-3.3 |

|

Ni |

0.81 |

0.794 |

-2.0 |

|

Ti |

0.086 |

0.083 |

-3.2 |

|

Li |

0.117 |

0.113 |

-3.7 |

|

Al |

Bal |

Bal |

Bal |

Comparing the results of the spectrographic analysis revealed that there was a greater loss than gain in compositions. The variations in Table 2 with the exception of iron which showed gain of 3.3% revealed that all the elements are affected during melting. Magnesium maintained loss of 3.3%; this could be due to excessive melting temperature and high volatility of Mg in molten form. The 3.3% gain in iron revealed there was iron pick up from the local crucible used.

Piston core samples are shown in figure 3 and the cast pistons are shown in figure 4 with the core sand still attached. A defect free casting can be obtained if the core is properly prepared and the melting and pouring processes properly carried out.

|

|

|

|

Figure 3. Piston Core |

Figure 4. Cast Pistons |

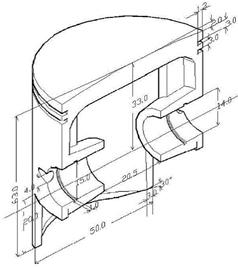

In this work, due to unavoidable errors, some defects were noticed on the cast piston. The internal surface of the cast piston was relatively rough (figure 5a) compared with the imported piston as shown in figure 5(b). However, the external surface of the cast piston was machined to obtain a higher degree of smoothness while for internal surface; there was little or nothing which could be done to better the smoothness. The machined piston with dimensions is shown in figure 6. The dimensional accuracy and surface finish was good.

|

a) |

b) |

|

Figure 5. Cast and Imported Piston Cavity |

|

|

a) |

b) |

|

Figure 6. Machined Piston with Dimensions |

|

During the first fifteen minutes of testing operation, there was rocking sound from the engine. The sound could be a result of piston run-in i.e. changes in the rubbing surfaces in the piston assembly. From the fifteenth minute upward the sound started reducing until it finally stopped at 35th minute and normal sound performance was heard. The black deposits on the cast piston dome shown in figure 7 are from oil, ash, fuel contaminants and unburned carbon. Depending on gasoline and oil used, normal deposits may also be brown, from light tan colour to almost black dark brown. Brown varnish on piston side below rings was baked oil from combustion gases blow-by caused by improper oil or poor ring sealing.

|

|

|

Figure 7. Tested Cast Piston |

The result of inspection after performance test is shown in Table 3. The piston performance test serve as confirmatory to a good casting process. Also it aimed at ensuring high-level performance/functionality throughout the intended life of the casting. The cast and imported pistons showed no sign of deformation around the groove area and also minimum deposits were observed around the grooves. The wear rate was also minimal. Keeping these critical areas clean and free of deposits and wear helps ensure longer engine life and signify good piston performance. The rating showed that the locally cast piston compared favourably with imported piston.

Table 3. Inspection Test Results

|

Inspected Area |

Rating |

|||

|

Wear |

Deposit |

|||

|

Locally Cast Piston |

Imported Piston |

Locally Cast Piston |

Imported Piston |

|

|

Oil Ring groove |

10 |

10 |

8 |

9 |

|

Compression groove |

10 |

10 |

8 |

9 |

|

Skirt wear |

8 |

9 |

- |

- |

|

Piston Pin bore |

9 |

10 |

- |

- |

|

Doom deposit |

10 |

10 |

4 |

7 |

|

Groove deformation |

No deformation |

|||

|

Ring stucking |

No stucking |

|||

Conclusion

The piston core prepared gave rough surface of internal cavity, this may be due to the fact that bigger sieve was used or proper percentage sand mix composition was not used. The aim to maintain the supposed composition of the LM29 when the scrap was melted could not be achieved. The spectrographic test result on cast piston indicated loss of most alloying elements due to their oxidation. Impurity control was done but this could not attain the desired result as could be seen from the defects found on the casting which may be due to entrapped air porosity problem encountered during the casting process though the defects are minor. Machining to specification was also a problem because the required tools were not available. The results of the test revealed favourable comparison for both the locally cast and imported pistons.

References

1. Kuttolamadom M.A., Hamzehlouia S., Laine Mears M., Effect of Machining Feed on Surface Roughness in Cutting 6061Aluminum, SAE International, 2010, p. 1-19.

2. Sears K.., Automotive Engineering: Strategic Overview 2, 1997, vol. 1, p. 55–68.

3. Miller W.S., Zhuang L., Bottema J., Wittebrood A.J., De SmetP., Haszler A., Vieregge A., Recent development in aluminium alloys for the automotive industry, Materials Science and Engineering: A, 2000, 280(1), p. 37-49.

4. Gaber A., Gaffar M.A., Mostafa M.S., Abo Zeid E.F., Precipitation kinetics of Al–1.12 Mg2Si–0.35 Si and Al–1.07 Mg2Si–0.33 Cu alloys, J. Alloys Compd., 2007, 429, p. 167-175.

5. Paray F.; Kulunk B., Gruzleski J.E., Impact properties of Al-Si foundry alloys, Int. Journal of Cast Metals Res., 2000, 13, p. 17-37.

6. Das S., Mondal D.P., Sawla S., Ramkrishnan N., Synergic effect of reinforcement and heat treatment on the two body abrasive wear of an Al–Si alloy under varying loads and abrasive sizes, Wear, 2008, 264, p. 47–59.

7. Mikhailov A.M., Metal Casting, First edition, Mir Publishers, Moscow, 1989.

8. Howard E.B., Timothy L.G., Metal Handbook, Desk edition, America Society for Metal (ASM) USA, 1992.

9. Ndaliman M.B., Pius P.A., Behavior of Aluminum Alloy Castings under Different Pouring Temperatures and Speeds, LEJPT, 2007, 11, p. 71-80.

10. Ozioko F.U., Development and Testing of a Permanent Mould for Casting AX 100 Motorcycle Engine Piston, M.Eng. Thesis (Unpublished), Federal University of Technology Minna, Niger State, Nigeria, 2011.