Table 2: Composition of bamboo leaf ash taken into study [19]

|

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

MgO |

K2O |

TiO2 |

|

75.9 |

4.13 |

1.22 |

7.47 |

1.85 |

5.62 |

0.20 |

Production of the Zn-27 Al based composites

Double stir casting process performed in accordance with Alaneme and Aluko [21] was adopted for the production of the composites. The amounts of bamboo leaf ash (BLA and silicon carbide (SiC) required to prepare 7 and 10 wt. % of the BLA-SiC reinforcements (in the Zn-27Al alloy matrix) was first determined using charge calculations. Four different BLA-SiC reinforcement weight mix ratios were prepared consisting of 0, 20, 30 and 40% BLA. Graphite (0.25 wt. %) was added to each charge for improved machinability of the composites after casting. In order to remove moisture, and improve wettability between the reinforcements and the molten Zn-Al alloy; preheating of the bamboo leaf ash, silicon carbide and graphite particles were performed separately at a temperature of 250°C. The melting operation was carried out using a gas fired crucible furnace. The Aluminium billets was charged into the furnace and heated to a temperature of 670°C until it has melted completely. (The temperature of the furnace was monitored during melting using a temperature probe fitted to the furnace). The temperature of the furnace was lowered to 500°C before Zinc was added in to the crucible and allowed to melt completely. The liquid alloy was then allowed to cool in the furnace to a semi solid state (temperature of 450°C); after which it was stirred at 200rpm for 5minutes to achieve homogenization. The preheated bamboo leaf ash, SiC and graphite particles were then charged into the melt and the ensuing slurry stirred for 5-10 minutes. The composite slurry was subsequently superheated to 530°C and second stirring performed using a mechanical stirrer. The stirring operation was performed at a speed of 400 rpm for 10 minutes before casting into prepared sand moulds. The sample designations for the different compositions of the Zn-27Al based composites produced are presented in Table 3.

Table 3: Sample designations for the composites produced

|

Sample designation |

Weight percent BLA:SiC |

|

7wt% Reinforcement |

|

|

A0 |

0: 100 |

|

A20 |

20:80 |

|

A30 |

30:70 |

|

A40 |

40:60 |

|

10wt% Reinforcement |

|

|

B0 |

0: 100 |

|

B20 |

20:80 |

|

B30 |

30:70 |

|

B40 |

40:60 |

Mechanical testing

Hardness tests (HRC) were performed on the composites produced using Indentec Hardness Testing Machine. The composite specimen surfaces were well polished following standard metallographic procedures to ensure a smooth surface is produced to allow for reliable measurement of the hardness values. Multiple hardness tests were performed on each sample and the average from values within the range of ± 2% was taken as the hardness of the specimen.

Tensile tests were also performed on the composites produced following the specifications of ASTM 8M-91 standards [22]. The samples for the test were machined to round specimen configuration with 6 mm diameter and 30 mm gauge length. The test was carried out at room temperature using an Instron universal testing machine operated at a strain rate of 10-3/s. The tensile properties evaluated from the tension tests are the ultimate tensile strength and the strain to fracture. Three repeat tests were performed for each grade of the Zn-27Al based composite produced to ensure repeatability and reliability of the data generated.

Circumferential notch tensile (CNT) specimens were used for the determination of the fracture toughness of the composites following specimen preparation and test procedures in accordance with Alaneme [23]. The CNT testing was also performed at room temperature using an Instron universal testing machine. The samples for the test were machined having gauge length, specimen diameter (D), and notch diameter (d) of 30, 6, and 4.5 in mm respectively; and notch angle of 60°. The specimens were subjected to tensile loading to fracture and the fracture load (Pf) obtained from the load – extension plots were used to evaluate the fracture toughness using the equation [24]:

|

K1C = Pf/(D)3/2[1.72(D/d)–1.27] |

(1) |

where, D and d are respectively the specimen diameter and the diameter of the notched section. Plane strain conditions and by extension, the validity of the fracture toughness values obtained was determined using the relations in accordance with Nath and Das [25]:

|

D ≥ (K1C/σy)2 |

(1) |

Three repeat tests were performed for each grade of the Zn-27Al based composite produced to ensure repeatability and reliability of the data generated.

Microstructural examination

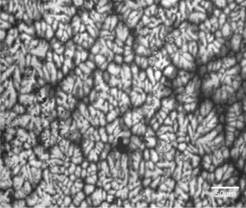

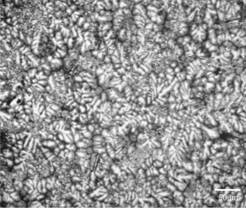

The microstructure of the composites was examined using a Zeiss Metallurgical Microscope with accessories for image analysis. The specimens for the test were metallographically polished and etched in dilute aqua regal solution before they were viewed under the microscope.

Corrosion test

The corrosion behaviour of the Zn-27Al alloy based composites produced was studied using weight loss method. The mass loss (g/cm2) and corrosion rate (mmy) measurements determined from the weight loss data (in accordance with ASTM G31 standard recommended practice [26]) were used to access the corrosion behaviour of the composites. The corrosion test was performed by at room temperature (25°C) by immersion of the test specimens in still solutions of 0.3M H2SO4 and 3.5% NaCl which were prepared following standard procedures. The specimens for the test were cut to size 15×15×10 mm and then mechanically polished with progressively finer grit size emery papers to produce a smooth surface. The samples were de-greased with acetone, rinsed in distilled water, and then dried in air before immersion in the solutions. The solution-to-specimen surface area ratio was about 150 ml cm-2, and the corrosion setups were exposed to atmospheric air for the duration of the immersion test. The weight loss readings were monitored on two day intervals for a period of 42 days. Three repeat corrosion tests were carried out for each grade of the Zn-27Al based composites produced to guarantee reliability of results generated.

Results and discussion

Microstructure

Representative microstructures of the Zn-27Al based composites reinforced with BLA and SiC are presented in Figure 1. For the two microstructural images, the dendritic solidification structure of the Zn-27Al alloy which serves as the composite matrix are visible alongside the dispersed reinforcements.

a.  b.

b.

Figure 1: Representative microstructures of (a) the Zn-27Al based composite containing 7 wt% BLA-SiC (with 20% BLA: 80% SiC in wt %) and (b) the Zn-27Al based composite containing 10 wt% BLA-SiC (with 30% BLA: 70% SiC in wt. %)

Mechanical behaviour

The results of the mechanical properties of the Zn-27Al alloy based composites produced are summarized in Table 3.

Table 3. Mechanical properties of Zn27Al based composites produced

|

Sample designation |

BLA (%) |

HRC |

UTS (MPa) |

E (%) |

KIC (MPam1/2) |

|

|

7wt% |

|

|

|

|

|

A0 |

0 |

26.2 |

273.2 |

6.55 |

7.3 |

|

A20 |

20 |

25.6 |

269.7 |

6.7 |

8.8 |

|

A30 |

30 |

24.7 |

266 |

6.9 |

10.2 |

|

A40 |

40 |

23.4 |

258 |

6.2 |

9.6 |

|

|

10wt% |

|

|

|

|

|

B0 |

0 |

28.3 |

316.8 |

6.3 |

7 |

|

B20 |

20 |

27.4 |

310.2 |

6.4 |

7.8 |

|

B30 |

30 |

26.7 |

292.4 |

6.5 |

9.6 |

|

B40 |

40 |

25.8 |

283.7 |

6.1 |

8.9 |

It is observed from Table 3 that the hardness and tensile strength of the composites decreased with increase in the weight percent of BLA. For hardness, reductions of 2.3, 5.7, and 10.6% was observed for the 7 wt% BLA-SiC reinforced Zn-27Al composite grades containing 20, 30, and 40% BLA (A20, A30, and A40) respectively. In the case of the 10 wt.% BLA-SiC reinforced Zn-27Al composite grades, 3.2, 5.6 and 8.8% reduction in hardness was observed for the composites containing 20, 30, and 40% BLA (B20, B30, and B40) respectively. For tensile strength, reductions of 1.3, 2.6 and 5.6% were obtained for the 7 wt% BLA-SiC reinforced Zn-27Al composite grades containing 20, 30, and 40% BLA (A20, A30, and A40) respectively. For the 10 wt% BLA-SiC reinforced Zn-27Al composite grades 2.1, 7.7 and 10.5% were observed for the composites containing 20, 30, and 40% BLA (B20, B30, and B40) respectively. For both cases of reduction in hardness and tensile strength with increase in BLA content, the predominance of silica in BLA (Table 2) which is known to be softer compared to SiC is largely responsible [19]. The percent elongation (%E) is observed to improve slightly with the addition of a maximum of 30% BLA content for both the 7 and 10 wt% composite grades. Further increase to 40% BLA content is noted to result in decrease in the % Elongation of the composites. The fracture toughness also increased with increase in the weight percent of BLA in both the 7 and 10 wt. % composite grades which is in contrast with the trend observed for the hardness and tensile strength. For the 7 wt.% BLA-SiC reinforced Zn-27Al composite grades, significant increases of 17.1 , 28.4 and 24.0 % were obtained for the composites containing 20, 30, and 40% BLA (A20, A30, and A40) respectively. In the case of the 10 wt.% BLA-SiC reinforced Zn-27Al composite grades 10.3, 27.1 and 21.4 % increment in fracture toughness was observed for the composites containing 20, 30, and 40% BLA (B20, B30, and B40) respectively. The improvement in the fracture toughness with increase in BLA content of the composites is due to the reduced amount of relatively harder and brittle SiC particles in the Zn-27Al based composites produced. The SiC particles like most hard and brittle ceramic particles have a higher tendency to undergo rapid crack propagation [19]. Thus it is noted that the addition of BLA in the Zn-27Al based composites results in improved resistance to crack propagation and fracture.

Corrosion behaviour

The results of the variation of mass loss and corrosion rate with exposure time for composites immersed in 3.5wt% NaCl solution are presented in Figures 2 and 3.

(a)

(b)

Figure 2. Variation of (a) mass loss, and (b) corrosion rate of Zn-27Al based composites containing 7 wt% BLA-SiC in 3.5% NaCl solution

(a)

(b)

Figure 3. Variation of (a) mass loss, and (b) corrosion rate of Zn-27Al based composites containing 10 wt % BLA-SiC in 3.5% NaCl solution

For the 7 wt% reinforced Zn-27Al based composite grades (Figure 2), it is observed from both the plots of mass loss (Figure 2a) and corrosion rate (Figure 2b) that there are consistent fluctuations in the mass loss and corrosion rate of the composites in NaCl solution over the exposure period for this study. This trend is linked to repeated film formation and breakdown on the surface of the composites. It is noted however that the composite grade containing 20% BLA had the highest resistance to corrosion of all the composites produced in this series. The fluctuating mass loss notwithstanding, the 20% BLA containing composite grade is observed to exhibit weight gain for most of the period of immersion. This suggests fairly steady film formation.

The composite with 40% BLA is observed to be the most susceptible to corrosion compared to the other composites in this series. This is a clear indication that proper selection of BLA/SiC mix ratio can result in improved corrosion resistance of the Zn-27 Al based composites in NaCl environment in comparison to the grades reinforced with only SiC.

For the 10 wt% reinforced composite grades (Figure 3), it is observed that the composites were relatively more stable in NaCl solution compared with the 7 wt % composite grades (Figure 2). The mass loss of the composites (Figure 3a) reduced significantly with the addition of 30 to 40% BLA compared with the other composite compositions in this series.

The progressive weight gain observed in the composite grades containing 30 and 40% BLA, is indicative of the consolidating nature of film deposition on the surface of the composites with continuous exposure in the NaCl solution.

Thus the oxide films formed are very stable in NaCl solution. Similar trend in improvement of corrosion resistance with the addition of BLA has been reported by Alaneme et al [19]. The trends observed from the mass loss results (Figure 3a) are supported by the corrosion rate plots (Figure 3b).

The variation of mass loss and corrosion rate with exposure time of the composites produced in 0.3M H2SO4 solution is presented in Figures 4 and 5.

(a)

(b)

Figure 4. Variation of (a) mass loss, and (b) corrosion rate of Zn-27Al based composites containing 7 wt% BLA-SiC in 0.3M H2SO4 solution

For the 7 wt% reinforced composite grades (Figure 4), it is observed from the mass loss plots (Figure 4a) that the corrosion resistance of all the hybrid composites was superior to that of the single reinforced composite grade.

This observation is supported by the corrosion rate plot (Figure 4b) where it is noted that peak corrosion rate was obtained at the third day of immersion. It is apparent that the corrosion resistance of the composites roughly improved with increase in the BLA content. This suggests that the addition of BLA (up to 40%) helps in stabilizing the passive film formed on the surface of the composites and hence improves its protective capacity.

For the 10 wt% reinforced composite grades (Fig. 5), it is observed from the mass loss (Fig. 5a) and the corrosion rate plots (Fig. 5b) that with the exception of the composite grade containing 30% BLA, the corrosion resistance of the hybrid composite grades containing 20 and 40% BLA was better than that of the single SiC reinforced composite grade. This corrosion trend is quite similar to that of the 7 wt% reinforced composite grades.

(a)

(b)

Figure 5. Variation of (a) mass loss, and (b) corrosion rate of Zn-27Al based composites containing 10 wt% BLA-SiC in 0.3M H2SO4 solution

Thus it can be stated the use of hybrid compositions of BLA and SiC in reinforcing Zn-27Al based composites results in improved corrosion resistance in H2SO4 environments in comparison with the use of single SiC reinforced Zn-27Al composite grade.

Conclusions

The mechanical and corrosion behavior of Zn27Al alloy based composites reinforced with 7 and 10 wt % BLA and SiC in varied weight ratios was investigated. The results show that:

· The hardness and tensile strength of the composites decreased with increase in the weight percent of BLA although less than 11% for all experimental cases studied.

· The percent elongation (%E) improved slightly with the addition of a maximum of 30% BLA content for both the 7 and 10 wt% composite grades.

· The fracture toughness increased consistently with increase in the weight percent of BLA in both the 7 and 10 wt. % composite grades.

· The hybrid composites were very stable in 3.5 % NaCl solution and the corrosion resistance in 0.3M H2SO4 solution was superior to that of the single SiC reinforced Zn-27Al composite grade.

References

1. Babic M., Mitrovic S., Ninkovic R. Tribological potential of zinc-aluminium alloys improvement, Tribology in industry, 2009, 31(1-2), p. 15-28.

2. Girish B.M., Prakash K.R., Satish B.M., Jain P.K., Prabhakar P. An investigation into the effects of graphite particles on the damping behavior of ZA-27 alloy composite material, Materials and design, 2011, 32, p. 1050–1056.

3. Babic M., Ninitrovic S., Jeremic B. The influence of heat treatment on the sliding wear behavior of a ZA-27 alloy, Tribology international, 2010, 43(1-2), p. 16-21.

4. Abou El-khair M.T., Lotfy A., Daoud A., El-Sheikh A.M. Microstructure, thermal behavior and mechanical properties of squeeze cast SiC, ZrO2 or C reinforced ZA27 composites, Materials science and engineering: A, 2011, 528(6), 2353-2362.

5. Sharma S.C., Girish B.M., Kamath R., Satish B.M. Effect of SiC particle reinforcement on the unlubricated sliding wear behavior of ZA-27 alloy composites, Wear, 1997, 213, p. 33–40.

6. Tjong S.C., Chen F. Wear behavior of As-cast ZnAl27/SiC particulate metal-matrix composites under lubricated sliding condition, Metallurgical and materials transactions A, 1997, 28(9), p. 1951–1955.

7. Prasad B.K. Abrasive wear characteristics of a zinc-based alloy and zinc-alloy/SiC composite, Wear, 2002, 252(3-4), p. 250–263.

8. Bobic I., Jovanovic M.T, Ilic N. Microstructure and strength of ZA27 based composites reinforced with Al2O3 particles, Materials letters, 2003, 57(11), p.1683–1688.

9. Bobic B., Mitrovic S., Babic M., Bobic I. Corrosion of aluminium and zinc-aluminium alloys based metal-matrix composites, Tribology in industry, 2009, 31(3-4), p. 44-52.

10. Bobic B., Venci A., Babic M., Mitrovic S., Bobic I. The influence of corrosion on the microstructure of thermally treated ZA27/SiCp composites, Tribology in industry, 2014, 36(1), p. 33-39.

11. Li Z,Q., Wu B.Y., Zhang S.Y. Pre-treatment process of SiC particles and fabrication technology of SiC particulate reinforced Zn-Al alloy matrix composite, Materials science technology, 2001, 17, p. 954–960.

12. Sharma S.C., Girish B.M., Kamath R., Satish B.M. Graphite particles reinforced ZA-27 alloy composite materials for journal bearing applications, Wear, 1998, 219, p. 162–168.

13. Suresha S., Sridhara B.K. Effect of addition of graphite particulates on the wear behavior in aluminium–silicon carbide–graphite composites, Materials design, 2010, 31(4), p. 1804–1812.

14. Aigbodion V.S., Hassan S.B., Dauda E.T., Mohammed R.A. Experimental study of ageing behaviour of Al‑Cu‑Mg/bagasse ash particulate composites, Tribology in industry, 2011, 33, p. 28‑35.

15. Alaneme K. K., Akintunde I. B., Olubambi P. A., Adewale T. M. Fabrication characteristics and mechanical behaviour of rice husk ash – alumina reinforced Al-Mg-Si alloy matrix hybrid composites, Journal of materials research and technology, 2013, 2(1), p. 60-67.

16. Madakson P.B., Yawas D.S., Apasi A. Characterization of coconut shell ash for potential utilization in metal matrix composites for automotive applications, International journal of engineering science and technology, 2012, 4(8), p. 1190-1198.

17. Olugbenga O.A., Akinwole A.A. Characteristics of bamboo leaf ash stability on lateritic soil in high way construction, International journal of engineering and technology, 2010, 2(4), p. 212-219.

18. Alaneme, K. K., Adewale, T. M. Influence of rice husk ash / silicon carbide weight ratios on the mechanical behaviour of aluminium matrix hybrid composites, Tribology in industry, 2013, 35(2), p. 163-172.

19. Alaneme, K. K., Ademilua, B. O., Bodunrin, M. O. Mechanical and corrosion behaviour of bamboo leaf ash – silicon carbide hybrid reinforced aluminium based matrix composites, Tribology in industry, 2013, 35(1), p. 25-35.

20. Vencl A., Bobic I., Arostegui S., Bobic B., Marinkovic A., Babic M. Structural, mechanical and tribological properties of A356 aluminium alloy reinforced with Al2O3, SiC and SiC + graphite particles, Journal of alloys and compounds, 2010, 506, p. 631-639.

21. Alaneme, K.K. and Bodunrin, M. O., Mechanical behaviour of alumina reinforced AA (6063) metal matrix composites developed by two – step stir casting process, Acta Technica Corviniensis - bulletin of engineering, 2013, 3, p. 105-110.

22. ASTM E 8M-91. Standard test method for tension testing of metallic materials (Metric), Philadelphia: Annual Book of ASTM Standards, 1991.

23. Alaneme K.K., Influence of thermo-mechanical treatment on the tensile behavior and CNT evaluated fracture toughness of Borax premixed SiCp reinforced aluminium (6063) composites, IJMME, 2012, 7, p.96–100.

24. Dieter, G.E. Mechanical metallurgy (S.I. Metric, Ed.), Singapore: McGraw-Hill, 1988.

25. Nath, S.K. and Das, U.K. Effect of microstructure and notches on the fracture toughness of medium carbon steel, Journal of naval architecture and marine engineering, 2006, 3, p.15–22.

26. ASTM G31. Standard guide for laboratory immersion corrosion testing of metals, Philadelphia: Annual book of ASTM standards, 2012.

27. Alaneme, K. K., Adewuyi, E. O. Mechanical behaviour of Al-Mg-Si matrix composites reinforced with alumina and bamboo leaf ash, Metallurgical and materials engineering, 2013, 19(3), p. 177-187.