Aluminium alloy - rice husk ash composites production and analysis

Abdullahi Mohammed USMAN1*, Abdulkabir RAJI2, Nuhu Hassan WAZIRI3 and Mudathir Abdulsalam HASSAN4

Mechanical Engineering Department, Modibbo Adama University of Technology, Yola, Adamawa State, Nigeria

E-mails: 1abunanakhadijat@gmail.com; 2rajifuty@yahoo.com; 3wazirinuhu@gmail.com; 4benulamaau@yahoo.com;

* Corresponding author, Phone: +2348082805353

Abstract

This study was carried out to produce and analyse the properties of Aluminium Alloy-Rice Husk Ash composites. Rice husk ash (RHA) with high silica content of up to 97.095% was used for the study with the RHA varied from 0vol% – 30vol% at intervals of 5vol% in the aluminium alloy as reinforcement. The density and some mechanical properties of the composites including tensile strength, impact strength, hardness and fatigue strength were investigated. The results showed that the density of the composite decreases with the percentage increase of reinforcement from 2840.242 kgm-3 for the control sample to 2402.899 kgm-3 for 30vol% RHA. The Ultimate Tensile Strength (UTS) varies from 164.374 MNm-2 at 0% RHA to 176.837 MNm-2 with maximum value at 10% RHA, impact strength values varies from 84.020kJm-2 at 0% RHA to 155.244 kJm-2 with maximum value at 10% RHA, hardness value varies from 70.467 RHV at 0% RHA to 109.367 RHV with maximum value at 25% RHA and fatigue strength varies from 0.224x106 cycles to 2.582x106 cycles with maximum cycle at 20% RHA. The results of analysis of variance showed that there are significant differences among the means of each property of the composites at different levels of replacement of the ash addition (P<0.05). It was concluded that the produced composites could be used to make engineering components such as automobile body parts, piston and block engine etc.

Keywords

Alumina; Aluminium alloy; Automobile; Composite; Mechanical properties; Rice husk ash; Scrap; Silica

Introduction

The possibility of taking advantage of particular properties of the constituent materials to meet specific demands is the most important motivation for the development of composites. A composite is a material made with several different constituents intimately bonded. This definition is very wide, and includes a lot of materials such as the Roman ways (constituted of different layers of stones, chalk and sand), wood, human body etc. A more restrictive definition is used by industries and materials scientists who described a composite as a material that consists of constituents produced via a physical combination of pre-existing ingredient materials to obtain a new material with unique properties when compared to the monolithic material properties. This definition distinguishes a composite from other multiphase materials which are produced by bulk processes where one or more phases result from phase transformation ("in situ" composites) [1, 2].

Composite materials are usually classified on the basis of the physical or chemical nature of the matrix, e.g., polymer matrix, metal-matrix and ceramic matrix composites. In addition, there are some reports to indicate the emergence of inter metallic-matrix and carbon-matrix composites. The matrix is a percolating “soft” phase (which in general has excellent ductility, formability and thermal conductivity) in which are embedded the “hard” reinforcements (high stiffness and low thermal expansion). The reinforcements can be continuous or discontinuous, orientated or disorientated [1, 3].

Aluminium is widely used as a structural material especially in the aerospace industry because of its light weight property. However, the low strength and low melting point were always a problem. A cheap method of solving these problem was the use of reinforcement element such as SiO2, SiC particles and whiskers or other elements or compounds as alloying element. The addition of ceramics and alloying elements particles makes it possible to increase the specific elastic modulus of aluminium, improve its thermal properties etc. Using several methods including powder metallurgy, stir-casting method, infiltration casting, direct-melt oxidation, hot dipping, and sintering of ball-mill activated mixture of powders etc to produce aluminium composite and alloys reinforced with particulates and other alloying elements will help to produce a homogenous distribution of reinforcement in matrix [4, 5].

Aluminium matrix composites gained much interest due to their superior properties compared to monolithic aluminium alloys. Strength, stiffness, wear resistance are among several properties which are improved by the hard reinforcement materials. Various processing methods have been reportedly used to achieve high performance metal matrix composites [5].

In general, agrictural waste disposal practice entails dumping it in bush, road sides, in water ways etc, and burning in open air. Sometime, the wastes and their ashes are scattered in agricultural fields as fertilisers. However, these practices cause the release of CO2 gas due to burning and disposal, while methane and other gases are released from the rotten agricultural wastes. A new reuse process of these wastes has to be established so as to reduce the environmental burden of the wastes, their ashes and gases [6, 7].

The need for metal matrix composites in engineering components for different structural applications has motivated the need to find a cost effective production methods for these composites. The addition of hard and stiff ceramic reinforcement has been established to improve the modulus behaviour and strength properties in the metallic matrices [2]. Reinforcing aluminium metal with rice husk ash as a source of silica particulate will yield a material that displays combination of physical and mechanical properties of both the metal matrix and the silica from the ashes.

In our previous work [8] rice husk from local millers in Girei town was burnt at various temperatures to determine its silica and alumina potentials.

The aim of this work is to utilise abundant rice husk ash potentials in the region by way of using it as reinforcement in the production of aluminium matrix composites thus reducing the negative environmental impact on the society; improving the economic utilisation of rice husk and aluminium matrix composites and developing new materials with superior mechanical properties.

Materials and methods

Material preparation

The rice husk was obtained from local millers at Girei market, Girei Local Government Area of Adamawa state in Nigeria. The rice husk comes with some rice grains and sand mixed together both in particles and powdered form which has to be separated before use. It was first blown manually to separate the husk from rice grains and some sand particles and then washed with tap water three times by stirring in a container to allow the sand particles to settle at the bottom while the powdered grains and sand mixed with the water and became muddy. This muddy water was then poured away and the rice husk was manually removed from the container leaving behind the settled sand. The blown and washed rice husk was then dried under sun rays for three days on stainless steel trays. The rice husk was then burnt at 700°C for two hours and the chemical composition of the RHA was determined as given in Table 1. The ash was further burnt at 1100°C for another two hours.

Aluminium scraps in form of automobile parts, aluminium sheets, canes and pipes etc. were obtained from scraps dealers in Girei market, Girei Local Government Areas of Adamawa state. The scrap was put together and melted in a crucible and cast in to cylindrical ingots. The elemental composition of the synthesized aluminium alloy ingot was determined as given in Table 2.

Table 1: Percentage chemical composition of rice husk ash burnt at 700°C

|

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

MgO |

SO3 |

K2O |

Na2O |

Others |

LOI |

|

97.095 |

1.135 |

0.316 |

0.073 |

0.825 |

0.146 |

0.181 |

0.092 |

Balance |

0.965 |

Table 2: Elemental percentage composition of synthesized aluminium alloy

|

Si |

Mn |

Fe |

Cu |

Zn |

Mg |

Cr |

Ti |

Al |

|

6.70 |

0.80 |

1.50 |

3.20 |

0.50 |

0.35 |

0.10 |

0.10 |

Bal |

Composites production

The percentage of the ash used for production of the composites was 0-30vol% at an interval of 5vol% and the samples were labelled control for 0 vol% and CRHA 1 to CRHA 6 for 5vol% - 30vol%. The production was carried out in an improvised mild steel container at a temperature of 800±20oC. Aluminium ingot was first weighed and put into the container and heated in the furnace for one hour forty minutes at a temperature of 800±20°C after which the reinforcement was added. This was followed by stirring the molten aluminium alloy and the ash for one minute then holding in the furnace at that temperature for 20 minutes. The molten composite was poured into a pipe mould of length of 30cm and diameter of 2 cm and allowed to cool at room temperature. The density and mechanical properties of the composite viz Ultimate Tensile Strength (UTS), impact strength, hardness and fatigue strength were then determined.

Determination of density and mechanical properties

The mass of the composite sample was determined using electric weighing balance shown in plate 1a and the volume was obtained through Archimedes principle by immersing the sample into a labelled measuring cylinder shown in Figure 1, plate 1b, and the rise in volume was recorded and used together with the mass to calculate the densities.

Figure 1. Density measuring apparatus (a) electric weighing balance and (b) measuring cylinder

The percentage decrease in densities was calculated using equation 1,

|

Percentage decrease = (1- ρn / ρcontrol) · 100 % |

(1) |

where ρn is the density of composite produce and ρcontrol is the density of the aluminium alloy.

The tensile strength was determined by first preparing the sample on a lathe machine and using Mosanto Tensometer shown in Figure 2 the ultimate tensile strength was determined and the results of average Ultimate Tensile Strength (UTS), elongation and Young Modulus (E) were calculated.

Figure 2. Mosanto tensometer

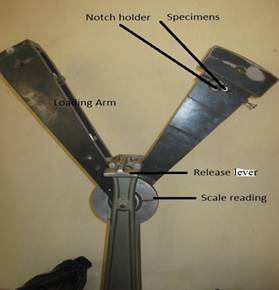

The impact strength test was carried out by preparing the sample on a lathe machine and tested on a Hounsfield Balanced Impact Strength Testing Machine shown in Figure 3. The sample was inserted into the notch hole and the load was released to impact the specimen while the reading was taken from the scale reading on the machine.

Figure 3. Hounsfield balance impact testing machine

The hardness was carried out on an Indentic Rockwell hardness testing machine shown in Figure 4. The hardness specimen was put on the sample position and the indenter of 1/16” (steel ball) was forced to indent on the specimen. The minor and the total load of the machine were 10 kg and 60 kg, respectively.

Figure 4. Indentic rockwell hardness testing machine

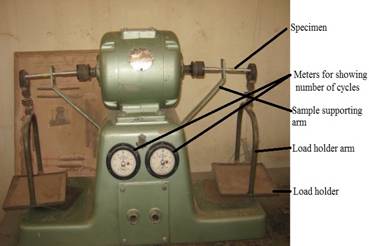

Fatigue strength was determined by loading the samples with a constant load of 80N and the number of cycles at which the samples failed was determined from the meter on the fatigue testing machine shown in Figure 5.

Figure 5. Fatigue testing machine with two samples

Using SPSS statistical tool software, the analysis of variance (ANOVA) among the mean data at all levels of reinforcement replacement was carried out.

Results

Table 3 and Figure 6 show the percentage decrease in densities and variation of density with the volume percentage rice husk ash addition, respectively. The values of Young modulus are given in Table 4 while the values of UTS and elongation, impact strength, hardness and fatigue strength are given in Figures 7 – 10.

Table 3: Percentage density decrease of Al-RHA composite

|

% Addition |

0 |

5 |

10 |

15 |

20 |

25 |

30 |

|

% Decrease |

0.00 |

1.763 |

3.096 |

5.627 |

8.850 |

12.591 |

15.398 |

Figure 6. Variation of densities with the percentage volume of RHA addition

From Tables 3 and Figure 6, it can be deduced that the density of the produced composites decreases with increase in the percentage volumes of RHA addition. The value decreases from 2840.242kgm-3 for the control sample to 2402.899 kgm-3 at 30% RHA. The decrease in densities result from the addition of low density RHA ash (397.114 kgm-3) which leads to the replacement of soft and high density matrix material (i.e. the synthesized aluminium alloy of density 2840.242 kgm-3) by hard and low density reinforcement material in the composites thereby giving the composites overall decrease in densities with addition of the ashes. This conforms to the results reported by Prasad and Krishna [9, 10] who obtained density from 2760 kgm-3 to 2570 kgm-3 for 2% - 8% RHA, Dhadsanadhep et. al, [11], who reported densities for 0-15% RHA from 2700kgm-3 for the control to 2120kgm-3, 1970 kgm-3, 2550 kgm-3 and 2690 kgm-3 for green, sintered, forged and theoretical densities respectively. It also conforms to Shanmughasundaram et al. [12], who reported 2700 kgm-3 – 2523 kgm-3 for 0 – 25% fly ash addition.

Table 4: Average Young modulus for CRHA and control

|

Sample |

Control |

RHA 1 |

RHA 2 |

RHA 3 |

RHA 4 |

RHA 5 |

RHA 6 |

|

E (MPa) |

1643.744 |

1792.319 |

1768.947 |

1666.859 |

1576.900 |

1420.530 |

1364.611 |

Figure 7. Variation of UTS and % elongation of composite with RHA addition (where the UTSMPA is the Ultimate Tensile Strength in MPa Mega Pascal (MNm-2))

From Figure 7, the ultimate tensile strength of composites increases from 164.374MPa for the control sample to 181.140 MPa at 10% RHA, the value then decrease approximately linearly to 139.736 MPa at 30% RHA. This shows that by increasing the ash percentage above 10% in the alloy, the strength decreases as the ash introduces more reinforcements in the matrix and hence more site for crack initiation and thus decreases the load bearing capacity of the composites leading to reduction in the tensile strength [13]. Besides, if the number of contacts between SiO2 particulates increases, then the particles will no longer be isolated by the ductile aluminium alloy matrix. Therefore, cracks will not get arrested by the ductile matrix and would propagate more easily between the SiO2 particulates. Furthermore, the elastic stresses generated due to the thermal mismatch put the reinforcement particles into compression and the matrix into tension. This residual stress affects the material properties around the reinforcement and the crack tips and the fracture toughness values would be altered. Consequently, these residual stresses would probably contribute to the brittle nature of composites [13]. Therefore, the maximum tensile strength is at 10vol% RHA with a value of 181.140 MPa. These results support the results reported by Neelima et. al. [14] who used silicon carbide and reported ultimate tensile strength increase from 80.84 MPa at 0% to 94.21 MPa at 15% and decrease to 83.00 MPa at 20%. The results also conform to Shanmughasundaram et. al. [12] who reported an increase in ultimate tensile strength with Fly ash from 77 MPa for 0% to 118 MPa for 15% and then a decrease to 104 MPa for 25% and Prasad and Krishna [9, 10] who reported an increase in ultimate tensile strength from 278 MPa at 0% to 313 MPa at 8% RHA. The results of ANOVA show that there is a significant difference among the means of UTS (P<0.05).

Figure 8. Variation of impact strength with RHA addition

From Figure 8, it can be seen that the impact strength of the composites rise from the control sample 84.020 Jm-2 up to 155.244 Jm-2 at 10vol% RHA and thereafter decreases. However, all the composites have better impact property as compared to the control sample up to 25vol%RHA addition with impact strength of 129.223 Jm-2, 101.027 Jm-2 and 91.080 Jm-2 for 15%, 20% and 25%, respectively. Significant difference exist among the means of impact strength at different levels of ash addition (P<0.05).

From Figure 9, it can be seen that the hardness of the composites produced with RHA increases approximately linearly from 70.467 HRV for the control sample to 109 HRV at 25vol% RHA and decreases to 79.033 HRV at 30vol% RHA. This shows that all the composites specimens had higher HRV than the control specimen; hence, the composites have better hardness property. The maximum HRV value was 109 HRV at 25vol%. These results are well in support of the results reported in Shanmughasundram et al. [12] who obtained increase from 19 BHN for 0% fly ash to 51 BHN for 20%fly ash and decrease to 45 BHN for 25% fly ash, Dhadsanadhep et al. [11] reported increase from 17 HRV at 0% to 30 HRV at 15% RHA. The trends also conform to result of some other researchers. Singla et. al. [15] obtained increase from 28.5 BHN for 0% SiC to 46 BHN for 25% SiC and decrease to 41 BHN for 30% SiC, Aigbodion et al. [16, 17] obtained increase from 35 HRV for 0% to 48HRV for 10% BA, Luangvaranunt et al. [5] reported 17HRV at 0% RHA to 48HRV and 45HRV at 15% RHA for reacted area and as-aged hardness, Prasad and Krishna [9, 10] reported increase of hardness from 68BHN at 0% RHA to 83BHN at 8% RHA. From Table 5 it can be seen that at 5% significance level, there is a significant difference among the means of the different HRV values.

Figure 9. Variation of Rockwell hardness value with RHA addition

Figure 10.Variation of the number of cycles with the percentage RHA addition

From Figure 10 it can be seen that the number of cycles at which the composites failed increases with the ash addition from 0.620x106 for the control sample to 2.582 x 106 at 20% ash and decreases to 0.224x106 at 30% for RHA addition. This implies that the fatigue strength of the composites increases with increases with ash addition up to 20% for RHA and decreases with further addition up to 30%. The particulate reinforced composites show improved fatigue behaviour compared to unreinforced alloy and such an improvement is attributed to the higher stiffness reinforcement material in the composites [18, 19]. For a given matrix material, the stress concentration in a composite where the matrix is surrounded by high stiffness reinforcement particles, is lower than in the unreinforced alloy. Since more of the load is being carried by the high stiffness reinforcement particles in the composite, therefore the matrix material in the composites will be subjected to lower stress than in the unreinforced alloy [18, 19].

Table 5. Analysis of variance for the density and mechanical properties

|

Result |

Sum of squares |

Degree of freedom |

F-Statistic |

Significance |

Remark |

|

Density |

484223.848 |

20 |

292.514 |

0.000 |

S |

|

UTS |

5021.198 |

20 |

18.287 |

0.000 |

S |

|

Young Modulus |

555516.454 |

20 |

12.970 |

0.000 |

S |

|

Impact Strength |

19173.966 |

20 |

428.574 |

0.000 |

S |

|

Hardness |

3436.312 |

20 |

473.046 |

0.000 |

S |

|

CRHA |

1.570E13 |

20 |

413.242 |

0.000 |

S |

The results of ANOVA show that there is significant difference among the means values of the fatigue strength at various levels of RHA addition (P<0.05) (Table 5).

Conclusions

From the research the following conclusions were made:

1. Rice husk ash can be successfully incorporated into aluminium alloy as reinforcement at a temperature of 800°C.

2. Incorporating rice husk ash into the aluminium alloy improves its mechanical properties together with its density.

3. The density of the composites decrease by up to 15.5% of its value in the control sample for 30vol% RHA.

4. The maximum ultimate tensile strength of Al-6.7 Si Alloy-RHA composite is 181.140 MPa and is up to 10.20% of the control sample at 10vol% RHA. At 15% RHA the strength is higher than that of the control sample.

5. The maximum impact strength of Al-6.7 Si Alloy-RHA composite is 155.244 kJm-2 and this is up to 84.8% higher than the control sample at 10vol% RHA and up to 25vol% RHA the composites have better impact strength compared with the control sample.

6. The maximum hardness of Al-6.7 Si Alloy-RHA composite is 109.367 RHV and this is up to 55.2% higher than the control sample at 25vol% RHA.

7. All the composites produced with RHA have better HRV values compared to the control sample.

8. The maximum fatigue strength of Al-6.7 Si Alloy-RHA composite is 2.582 x 106 cycles and this is up to 316.5% higher than the control sample at 20 vol% RHA.

9. The result of analysis of variance showed that there is a significant difference among the means of each property of the composites at different levels of replacement of RHA addition (P<0.05).

10. The composites produced can be used to make automobile engine parts such as block engine, piston, brake parts etc.

Recommendations

1. The use of aluminium - RHA composites should be encouraged for production of engineering components.

2. Other methods of production such as powder metallurgy, die casting etc. should be used to produce aluminium alloy - RHA composites.

3. Other test such as wear test, heat and electric conductivity test etc. should be conducted to fully characterise the composite.

4. The load for the fatigue test should be varied to determine the optimum load and number of cycles of failures.

Acknowledgements

Authors will like to express their appreciations to Mechanical Engineering Department of Modibbo Adama University of Technology, Yola for sponsoring the research and Mechanical and Metallurgical Engineering departments of Ahmadu Bello University, Zaria for giving them access to their equipment.

References

1. Surappa, M. K., Aluminium matrix composites: challenges and opportunities, Sadhana India, 2003, 28(1 & 2), p. 319-334.

2. Zuhailawati, H., Samayamutthirian, P., Mohd Haizu, C. H., Fabrication of low cost of aluminium matrix composite reinforced with silica san, Journal of physical science, 2007, 18(1), p. 47-55.

3. Mallick, P., Fiber reinforced composites materials, manufacturing and design, Boca Raton, FL CRC Press, 2008.

4. Khairaldien, W. M., Khalil, A. A., Bayoumi, M. R., Production of aluminium-silicon carbide composites using powder metallurgy at sintering temperature above aluminium melting point. Journal of material science and engineering, 2005, A399, p. 822-831.

5. Luangvaranunt, T., Dhadsanadhep, C., Umeda, J., Nisaratanaporn, E., Kondoh, K., Aluminum-4 mass%Copper/Alumina composites produced from aluminum copper and rice husk ash silica powders by powder forging, Materials transactions, 2010, 51(4), p. 756-761.

6. Roy, G. K., Augustine, B., Recovery of chemical from agrictural residue-a critical view, Journal of Institute of Engineers, 1981, 62(1), p. 36-41.

7. Katsuyoshi, K., Hideki, O., Junko, U., Takateru, U., Innovative reuse of agricultural waste as industrial raw material to form magnesium composite, Material transactions, 2005, 46(1), p. 2586-2591.

8. Usman, A. M., Raji, A., Waziri, N. H., Characterisation of girei rice husk for silica potential, IOSR Journal of environmental science, Toxicology and food technology., 2014, 8(1) Version V, p. 68-71.

9. Prasad, D. S., Krishna, A. R., Fabrication and characterization of A356.2-rice husk ash composite using stir casting technique, International journal of engineering science and technology, 2010, 2(12), p.7603-7608.

10. Prasad, D. S, Krishna, A. R., Production and mechanical properties of A356.2 RHA composites, International journal of advanced science and technology, 2011, 33, p.51-58.

11. Dhadsanadhep, C., Luangvaranunt, T., Umeda, J., Kondoh, K., Fabrication of Al/Al2O3 composite by powder metallurgy method from aluminum and rice husk ash, Journal of metals, Materials and minerals, 2008, 18(2), p.99-102.

12. Shanmughasundaram, P., Subramanidan, R., Prabhu, G., Some studies on aluminium – fly ash composites fabricated by two step stir casting method, European journal of scientific research, 2011, 63(2), p.204-218.

13. Hamouda, A. M. S., Sulaiman, S., Vijayaram, T. R., Sayuti, M., Ahmad, M. H. M., Processing and characterisation of particulate reinforced aluminium silicon matrix composite, Journal of achievements in materials and manufacturing engineering, 2007, 25(2), p.11-16.

14. Neelima, D. C., Mahesh, V., Selvaraj, N., Mechanical characterization of aluminium silicon carbide composite, International journal of applied engineering research, 2011, 1(4), p.793-799.

15. Singla, M., Dwivedi, D. D., Singh, L., Chawla, V., Development of aluminium based silicon carbide particulate metal matrix composite. Journal of minerals & materials characterization & engineering, 2009, 8(6), p. 455-467.

16. Aigbodion, V. S., Hassan, S. B., Dauda, E. T., Mohammed, R. A., The development of mathematical model for the prediction of ageing behaviour for Al-Cu-Mg/Bagasse ash particulate composites, Journal of minerals & materials characterization & engineering, 2010, 9(10), p. 907-917.

17. Aigbodion, V. S., Hassan, S. B., Dauda, E. T., Mohammed, R. A., Experimental study of ageing behaviour of Al-Cu-Mg/Bagasse ash particulate composites, Tribology in industry, 2011, 33(1), 28-35.

18. Donahue, D. R., Fabiyi, P. A., Manufacturing feasibility of All- Aluminum automotive engines via application of high silicon aluminum alloy, Society of automotive engineers, 2000.

19. Chawla, K. K., Chawla, N., Metal matrix composites, Boston, Kluwer academic publishers, 2004.