Effects of selected casting methods on mechanical behaviour of Al-Mg-Si alloy

Henry Kayode TALABI1, Oluyemi Ojo DARAMOLA1*, Akinlabi OYETUNJI1 and Benjamin Omotayo ADEWUYI1

1Metallurgical and Materials

Engineering Department,

E-mails: thenrykayode@yahoo.com, ojaythompsoms@yahoo.com* akinlabioyetunji@yahoo.com, tayo_adewuyi@yahoo.com,

*Corresponding Author, Phone: +2348166814002

Abstract

This study investigated the effects of selected casting methods on mechanical behaviour of Al-Mg-Si alloy. The casting methods used was spin, sand and die casting, these were done with a view to determine which of the casting methods will produce the best properties. The pure aluminium scrap, magnesium and silicon were subjected to chemical analysis using spectrometric analyzer, thereafter the charge calculation to determine the amount needed to be charged into the furnace was properly worked out and charged into the crucible furnace from which as-cast aluminium was obtained. The mechanical properties of the casting produced were assessed by hardness and impact toughness test. The optical microscopy and experimental density and porosity were also investigated. From the results it was observed that magnesium and silicon were well dispersed in aluminium matrix of the spin casting. It was observed from visual examination after machining that there were minimal defects. It was also observed that out of the three casting methods, spin casting possesses the best mechanical properties (hardness and impact toughness).

Keywords

Al-Mg-Si alloy; Spin; Sand; Die casting; Spectrometric analyzer

Introduction

Casting is a fabrication process whereby a totally molten metal is poured into a mould cavity having the desired shape; upon solidification, the metal assumes the shape of the mould but experience some shrinkage [1]. Casting is the most economical of all fabrication processes.

A number of different casting techniques are commonly employed, including sand, die, investment, continuous and spin casting. Sand casting probably is the most common method, when ordinary sand is used as the mould material [1]. A two-piece mould is formed by packing sand around a pattern that has the shape of the intended casting. A gating system is usually incorporated into the mould to expedite the flow of molten metal into the cavity and to minimize internal casting defects. It has been stated that when pouring temperature is lower than optimum, the mould cavity will not fill the gate or riser will solidify too rapidly and intercept directional solidification. Die casting is a versatile process capable of being used in mass production of alloys having properties unobtainable by other manufacturing method [2].

Spin casting is both gravity and pressure independent since it creates its own force feed using a temporary sand mould held in a spinning chamber at up to 300-3000rpm as the molten metal is poured. The molten metal is centrifugally thrown towards the inside mould wall, where it solidifies after cooling. The casting is usually a fine-grained outer diameter, owing to chilling against the mould surface. Impurities and inclusion are thrown to the surface of the inside diameter which can be machined away [3].

Aluminium alloys have great use potential in the structural components in the aerospace and automobile industries mainly because of their low density and high specific strength [4], also aluminium alloy have a wide diversity of industrial applications because of their high specific strength, light weight and corrosion resistance. Therefore these alloys motivate considerable interest to the aviation industries [5, 6]. Aluminium alloy for a cast component is based upon mechanical and corrosion properties it can achieve. Aluminium alloy casting properties result from three primary factors: casting alloy, melting and casting methods [3]. The properties obtained from one particular combination of these factors may not be identical to those achieved with the same alloy in a different casting facility. The aim of this work is to study the effects of spin casting, sand casting and die casting methods on the mechanical properties of Al-Mg-Si alloy.

Material and method

The materials used for

the work were scraps of Aluminium (pure Al) purchased from Northern Nigeria

Cable Processing Company Limited (NOCACO),

Three casting methods were carried out for the work, they are: (i) die casting (ii) spin casting and (iii) Sand casting.

The patterns used were made of wood with diameters of 22 mm by 155 mm long. The patterns were made larger than the original dimension to compensate for shrinkage during solidification and machining operation.

Natural sand was used to prepare the sand mould, a mixture of silica sand with considerable amount of bentonite. The addition of bentonite improved the bonding strength. The molding of the pattern was carried out using a moulding box comprising of cope and drag that gave rigidity and strength to the sand. Parting sand was properly applied for the easy removal of the mould from the pattern. The gating system was properly designed for smooth channeling of the molten metal into the mould cavities through the sprue, runner, in-gates and riser that were perfectly placed in position. The same mould preparation were carried out for both spin and sand castings. The die mould was prepared using cast iron.

The cast aluminium scraps, magnesium and silicon were carefully worked out and charged into the furnace.

Table 1. Chemical composition of aluminium scraps

|

Si |

Fe |

Cu |

Mn |

Mg |

Zn |

Cr |

Ti |

Al |

|

0.40 |

0.24 |

0.03 |

0.04 |

0.55 |

0.03 |

0.01 |

0.02 |

98.68 |

Melting and casting

Crucible furnace was used for the melting of the charges. Prior to charging, the crucible furnace was checked to prevent leak of molten metal and also to guide against moisture, which can generate vapour during melting. Metallurgical factors in the choice of melting facilities related to the tendency of the charge to react with its surrounding, affecting composition control, impurity level and metallic yield were considered. The charged materials in the furnace were allowed to melt down (at 700°C) and then the furnace was switched off. The molten metal was tapped from the furnace, then poured into the die mould, sand mould and spin casting machine mould, on the spin casting mould, molten metal was centrifugally thrown towards the inside mould where it solidifies after cooling. The die cast was allowed to air cooled [2], together with sand and spin casting products.

Fettling and cleaning operations

The removal of the sand which stuck on the surface of the sand cast and spin cast were carried out with the aid of sand blasting bar, sprue and ingates were also removed using hacksaw. Cleaning operation was also performed by grinding to smoothen the surface and unnecessary attachment on the surface of the metal to improve the appearance.

Density measurement

The determination of the experimental densities of the various casting products were carried out measuring the weight of the test samples using a high precision electronic weighing balance with a tolerance of 0.1mg. The weights of the measured samples were divided by their respective volume.

|

Experimental density = Mass sample/Volume of sample |

(1) |

The percentage porosity of the cast aluminium was determined by use of equation

|

%Volume porosity = (ρcal – ρexp)/ρcal |

(2) |

where ρcal = Theoretical density (g/cm3), ρexp = Experimental density (g/cm3) [7, 8]

Table 2: Theoretical and experimental densities of cast Al-Mg-Si alloy with percentage porosity

|

Type of casting |

Theoretical density (g/cm3) |

Experimental density (g/cm) |

Porosity (%) |

|

Spin casting |

2.70 |

2.69 |

0.37 |

|

Sand casting |

2.70 |

2.67 |

1.11 |

|

Die casting |

2.70 |

2.67 |

1.11 |

Microstructure

The specimens for the optical microscopy were properly polished using emery papers of various grit sizes ranging from 500µm to 50000µm. The fine polishing was equally ensured using a polycrystalline diamond suspension of particle sizes ranging from 10µm to 0.5µm with ethanol solvent, after which the specimens were etched in HNO3. Hydrochloric acid was used to swab the surface before microstructural examination was performed using Datteng- Driven Metallurgical Software [9].

Hardness measurement

The hardness for the spin, sand and die cast were evaluated using a Vickers Hardness Tester (LECOAT 700 Microhardness Tester). Six test specimens for each casting process were polished to obtain flat and smooth surface finish after this, a direct load of 490.3 MN was applied on the specimens for 10 seconds and the hardness reading evaluated following standard procedures, the average readings were calculated and recorded as the hardness.

Impact test

The toughness of the specimens were evaluated using (Honnsfield Balance) Impact Testing Machine, six specimens for each of the casting process were machined to dimensions of 8mm diameter and 18mm length. The specimens were notched 2mm in (V shape), the value of the energies absorbed in fracturing the test - piece were measured in joule and the average readings were calculated and recorded as the impact strength

Results and discussion

Microstructure

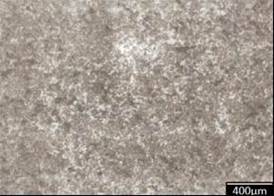

Figures 1 - 3 show representative optical micrograph for spin, sand and die casting of Al-Mg-Si alloy.

Figure 1. Micrograph of spin cast Al-Mg-Si alloy (X 400)

Figure 2. Micrograph of sand cast Al-Mg-Si alloy (X 400)

Figure 3. Micrograph of die casting (X400)

It is observed that magnesium and silicon were well dispersed in the aluminium matrix better in spin casting than sand and die casting; this is as a result of rotational movement of the mould during casting. The microstructure of sand casting shows phases that were not evenly dispersed in the aluminium matrix while there is strong clustering of Mg2Si in certain area of matrix [10, 11]

Hardness and impact properties

The hardness and Impact Strength of the various cast samples are presented in Table 3-4 and Figures 4-5.

Table 3. Hardness of cast Al-Mg-Si alloy products

|

Casting methods |

Handness for each sample (MPa) |

Average hardness (MPa) |

|||||

|

------------------ |

1 |

2 |

3 |

4 |

5 |

6 |

--------------- |

|

Spin casting |

501.234 |

499.362 |

500.876 |

500.234 |

502.102 |

498.604 |

500.402 |

|

Sand casting |

416.222 |

417.002 |

417.256 |

416.765 |

418.929 |

415.498 |

416.945 |

|

Die casting |

366.845 |

367.422 |

367.854 |

366.342 |

366.002 |

367.702 |

367.027 |

Table 4. Impact toughness of cast Al-Mg-Si alloy products

|

Casting methods |

Impact Values (Joules) for each Sample |

Average impact values(Joules) |

|||||

|

------------------ |

1 |

2 |

3 |

4 |

5 |

6 |

----------------- |

|

Spin casting |

50.014 |

51.110 |

49.890 |

50.352 |

50.840 |

53.914 |

51.025 |

|

Sand casting |

43.921 |

43.002 |

39.841 |

43.988 |

42.113 |

42.225 |

42.515 |

|

Die casting |

38.253 |

36.896 |

37.844 |

36.654 |

36.925 |

37.978 |

37.425 |

It was observed in Table 3 and Figure 4 that spin casting has the highest hardness, followed by sand and die casting. The crystal lattices of Mg2Si precipitates show coherence with that of the α-aluminium, consequently, severe strain fields are created around these crystals which impede the motion of dislocations and thereby causing increased hardness of castings obtained in spin casting [11]. Spin casting has the uniform microstructure, making it to have the best hardness property [12]. The variation found in hardness of the three cast products may also be attributed to their porosity, density and the microstructure.

Figure 4. Hardness of cast Al-Mg-Si alloy (Vickers BS EN ISO6507)

Figure 5. Impact toughness of cast Al-Mg-Si alloy

From Figure 5, the impact toughness of spin casting is superior to that obtained in sand and die casting. The results indicate that uniformly distributed Mg2Si crystals in α-aluminium in spin casting, this alloy exhibited better impact toughness in the spin cast condition compared with the same alloy subjected to sand and die casting; this is in agreement with Basavakumar [13]

Conclusions

In the research work, the effect of selected casting methods on mechanical behaviour of Al-Mg-Si alloy in NaCl and H2SO4 were investigated. From the results presented, the following conclusions were drawn:

a) The microstructure of the spin casting revealed that magnesium and silicon were well dispersed in the aluminium matrix as compared to sand die casting.

b) The hardness obtained from spin casting was better than that of sand and die casting.

c) The products through spin casting had a better impact toughness than sand and die casting

References

1. Callister W.D., Fundamentals materials science and engineering, Ranjbaran , Wiley and Sons Inc. USA, 2010 p. 364-578.

2. Adewuyi B.O and Omotoyinbo J.A., Effect of cooling media on the mechanical properties and microstructure of sand and die casting aluminium alloys. Journal of science and technology, 2008, 28, p. 97-100.

3. Polmear I.J; Production of aluminium. Light alloys from traditional

alloys to nanocrystals.

4. Yazdiam N., Kazimzadeh F., Tovoosi M., Microstructural evolution of nanostructure 7075 aluminium alloy during isothermal annealing, Journal of alloys and compounds, 2010, p. 137-141.

5. Prabhu C., Suryanarayana C., An L., Vaidyanathan R., Synthesis and characterization of high volume fraction Al-A1203 nanocomposite powders by high energy milling. Journal of material science engineering, 2006, 425(1-2), p.192-200.

6. Torralba J.M., Velasco F; Costa C.E., Vergara I., Caceres D., Mechanical behaviour of the interphase between matrix and reinforcement of Al 2014 matrix composites reinforced with (Ni3Al)p, 2002.

7. Hizombor M., Mirbagheri S.M.H., Abdideh R., Casting of A356/TiB2p composite based on the TiB2p/CMC/PPS mortar roznov pod radhostem, Czech Republic, 2010, 5, p.18-20

8. Hashim J., Looney L., Hashim M. S. J., Metal matrix composites: production by stir casting method, Mat. proc. tech 1999, 92, p. 1-7.

9. Yussof Z, Ahmed K.R and Jamaludin S.B., ‘Comparative study of corrosion behaviour of AA 2014/15vol%Al2O3P and AA2009/20vol% SiCw’ Portugaliae electrochemica acta, 2008, 26, p 291-301.

10. Adeosun O.S., Sekunowo O.I., Balogun S.A and Obiekea V.D., Corrosion behaviour of heat- treated aluminium-magnesium alloy in chloride and EXCO environments. International journal of corrosion, 2011, 2, p.1-9.

11. Ayoola A.W., Adeosun S.O., Sanni O.S., and Oyetunji A., Effect of casting mould on mechanical properties of 6063 aluminium alloy, Journal of engineering science and technology, 2012, 7(1), p.89-96.

12. Cheng Y.C., Lin C.K., Tan A.H., and Hsu S.Y., Effect of the spinning deformation processing on mechanical properties of Al-7Si-0.3Mg alloys. Journal of materials engineering, 2010.

13. Basavakumar K.G., Mukunda P.G., Chakraborty M., Impact toughness in Al-12Si and Al-12Si and Al-12Si-3Cu cast alloys- Part 1: Effect of process variables and microstructure. International journal of impact engineering, 2008, 35, p. 199-205.