Assessment of dynamic modulus of high density polypropylene waste fiber reinforcement in asphalt concrete

Hassan Suleiman OTUOZE1,*, Yusuf Dada AMARTEY1, Manasseh JOEL1,

Raheem Omuya MOMOH2, Abdulmumin Ahmed SHUAIBU1, and Kudirat Oziohu YUSUF1

1Department of Civil Engineering, Ahmadu Bello University, Zaria, Nigeria

2Department of Chemical Engineering, Ahmadu Bello University, Zaria, Nigeria

E-mails: *hassanotuoze@yahoo.com; dadaamartey@yahoo.co.uk, manassehjoel@yahoo.com; omuyar2002@yahoo.com; abdulshub4u@gmail.com; kudiratoziyusuf@yahoo.com

* Corresponding author, phone: +2348032895989

Abstract

Traditional asphalt tests like Hveem and Marshall tests are at best mere characterization than effective test of pavement field performance because of complex viscoelastic behavior of asphalt. Mechanical properties otherwise called simple performance tests (SPT) are performance criteria of asphalt. Dynamic modulus among other SPT’s like permanent deformation, fatigue cracking, thermal cracking, moisture susceptibility, shear and friction properties; determines stress-strain to time-temperature relationships that imparts on strength, service life and durability. The test followed the recommendations of NCHRP 1-37a (2004) and mixes were prepared using 0, 0.5, 1.0 and 1.5% HDPP contents. The parameters tested for dynamic modulus, /E*/, are stiffness, recoverable strain (ε), and phase angle (ɸ). Time – temperature superposition (TTS) called master curve was fitted using sigmoidal curve to interpolate the parameters beyond measured data set so as to observe the viscoelastic behavior outside the physical properties. The performance of 0.5% HDPP asphalt is better enhanced than the conventional asphalt to improve upon strength, service and durability.

Keywords

Asphalt; High density polypropylene; Dynamic modulus; Stiffness; Phase angle; Strain

Introduction

Bituminous pavement surface is susceptible to temperature and loading variation because of its viscoelastic and possibly plastic properties [1]. Conventional asphalt pavements lack the mechanical strength, service requirements and longevity to withstand heavy traffic loading, varying regimes of temperature loading and distresses induced climatic and environmental conditions [2]. It is important to assess the performance of fiber reinforcement materials to withstand mechanical failures [3].

Field performance problems of asphalt are manifested in terms of permanent deformation, fatigue cracking, thermal cracking, moisture susceptibility and friction properties [4]. Mechanical properties are used to characterize hot mix asphalt (HMA) in flexible pavement systems and give insight into performance as constitutive materials relationship [5]. Simple performance tests (SPT) have been recommended by [6] to evaluate the properties and parameters that measure the performance and durability [7].

SPT are used to simulate actual field performance using laboratory mix design as information provided by Hveem and Marshall are not adequate to understand the behavior of HMA owing to poor correlation, between stability and flow otherwise called Marshall Quotient [8]. Since none of the methods is capable of predicting rutting in HMA under traffic service [9], the effort in performance testing of HMA is to evaluate physical tests that can satisfactorily characterize key performance parameters and how these parameters change throughout the life of a pavement. [10] showed that the Simple Performance Tests (SPT) are accurate and reliable and could measure mixture response or characteristics that are correlated with the occurrence of pavement distress by traffic and climatic conditions [11].

Some of the SPT criteria that imparts on pavement performances are mix stiffness or dynamic modulus, resilient modulus, creep, wheel tracking and shear tests [12]. As one of the asphalt SPT criteria, dynamic modulus is a performance cum mechanical strength property [13].

The use of HDPP waste provides opportunity to improve upon problems of failure on our highways. Approximately 30,000,000 tons of HDPP is consumed worldwide in 2001 [14] and the products generate monumental waste after their useful service life [15]. The usage of HDPP waste materials in asphalt mix is expected to increase pavement life, reduce maintenance cost and reduce negative effect of waste on the environment and health.

The research is aimed at evaluating dynamic modulus of high density polypropylene waste fibres in asphalt mix which influences the strength characteristics, load-resistance, field performances and visco-elastic properties of hot-mix asphalt (hma).

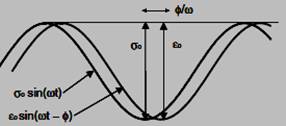

Dynamic modulus test is carried out by applying load sinusoidal to specimen over a range of different temperature and different frequencies [16]. Applying a repeated load at varying frequencies to a test specimen over a relatively short period of time, specimen’s recoverable strain and permanent deformation were determined at different temperatures and different frequencies [17]. Some dynamic modulus tests are also able to measure phase angle, which provides insight into a material’s viscous properties [4]. Figure 1 is a depiction of typical dynamic modulus. For visco-elastic tendencies of materials, according to [11], “complex modulus” (E*) is related by:

![]()

where E* = complex modulus, |E*| = dynamic modulus, φ = phase angle – the angle by which εo lags behind σo; φ = 0 pure elastic material, and the complex modulus, E* =|E*|. For pure viscous materials, φ = 90°, i = imaginary number.

The dynamic modulus which is the absolute value of the complex modulus, |E*|, shown in Figure 1 is calculated by the relationship according to [11] as follows:

![]()

where |E*| = dynamic modulus, δ0 = peak stress amplitude (applied load / sample cross sectional area), ε0 = peak amplitude of recoverable axial strain = ∆L/L, L = original gauge length over which the sample deformation is measured.

Figure 1. Dynamic (complex) modulus test (27)

The various types of dynamic modulus tests are unconfined, confined and shear dynamic modulus tests. Recommendations for carrying out dynamic modulus test by [10] in simple performance test (SPT) are frequencies of 25, 10, 5, 1, 0.5, and 0.1Hz while temperature range are -10, 4, 20, 38 and 54.4°C.

To truly assess interdependency between physical quantities and change of viscoelastic properties of asphalt, time – temperature superposition (TTS) is necessary to fit a master curve [18, 19]. A reference frequency or time at which data is taken is chosen [20] and data at other frequencies or time are applied with shift factor to fit a smooth curve called Sigmoidal curve fitting [21]. The Sigmoidal curve allows for interpolation of dynamic modulus and phase angle at an expanded frequencies and temperatures beyond the collected data sets [22]. This relationship is given by:

![]()

or

![]()

where |E*| = dynamic modulus or stiffness (Pa or Psi), fr = Reduced frequency (Hz), tr = reduced loading time (s), δ = Minimum modulus value, α = Span of modulus value, β, γ = Shape parameters

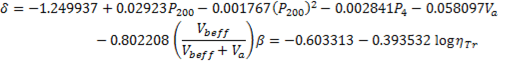

Equations 2 and 3 were compared by [23] and concluded the predictive equation having:

![]()

where ![]() = dynamic

modulus, 105 psi, δ = minimum value of E*, δ +

α = maximum value of E*,

= dynamic

modulus, 105 psi, δ = minimum value of E*, δ +

α = maximum value of E*, ![]() = binder

RTFOT viscosity at the reference temperature, 106 Poise, Va

= air void content, % Vbeff = effective binder content, % by

volume and

= binder

RTFOT viscosity at the reference temperature, 106 Poise, Va

= air void content, % Vbeff = effective binder content, % by

volume and

![]()

The master curve shift factor is a time-temperature superposition and could be adapted from Arrhensius shift factor law given by:

![]()

where ![]() = Shift factor at temperature,

T, R = Ideal gas constant = 8.314J/mol·K, Tr = Reference temperature

in Kelvin, usually taken at 21°C or 294.15K according to [24],

= Shift factor at temperature,

T, R = Ideal gas constant = 8.314J/mol·K, Tr = Reference temperature

in Kelvin, usually taken at 21°C or 294.15K according to [24], ![]() = Activation energy which is

the minimum energy required for intermolecular movement. The value of

= Activation energy which is

the minimum energy required for intermolecular movement. The value of ![]() below reference temperature (Tr)

may be taken as 261kJ/mol [9], C = constant whose values

were reported by different researchers to be 10920, 13060 and 7680K [25]

below reference temperature (Tr)

may be taken as 261kJ/mol [9], C = constant whose values

were reported by different researchers to be 10920, 13060 and 7680K [25]

Finally, the reduced frequency, fr, is given by:

![]()

![]()

where f = reference temperature’s loading frequency.

Material and method

According to [26] Marshall specimens were prepared with 25.4mm maximum sieve size coarse aggregates, river sand, cement filler and 60/70 penetration bitumen with adequate quality inferences. The dynamic modulus test was carried out using Simple Performance Tester (SPT) or Asphalt Mixture Performance Tester (AMPT) of International Process Control (IPC) global test machine otherwise called Universal Test Machine load 25kN pneumatic (UTM-25P) in accordance with [27] method. It delivered a constant pressure of up to 2800 kPa in an environmental chamber conditioned to testing temperatures of 4.4, 21.1, 25, 45 and 60°C to simulate ambient environmental temperature.

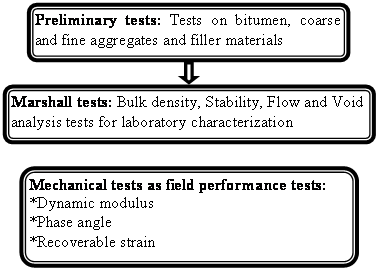

The summary of the workflow chronology in the research is shown in Figure 2.

![]()

Figure 2. Schematic diagram of research workflow

Test was accomplished by using gluing gauge plugs onto the specimen sides and attached to Linear Variable Differential Transducer (LVDT) to determine the displacement. A haversine dynamic loading (Pd) was adjusted such that axial strains lie between 75 and 125 microstrain (μm/m) without necessarily impacting in a cyclic manner. For each of HDPP fibre asphalt mixes, three (3) specimen replicates were prepared. Following the recommendations of [27] test loading frequencies considered were 0.1, 0.5, 1, 5, 10 and 25 Hz respectively. The recommended target percentage air void by [28] is 7±1.0%.

Results

The result of shift factor, reduced frequency, dynamic modulus, phase angle and the recoverable strain for the control mix (0% HDPP) are shown in Tables 1.

Table 1. Results for 0% HDPP Asphalt

|

Temp. (°C) |

Frequency (Hz) |

Shift factor |

Reduced frequency (Hz) |

Dynamic modulus (MPa) |

Phase angle (deg) |

Recoverable strain (mm/mm) |

|

4.4 |

25 |

1.5616 |

911.045377 |

1.66E+04 |

15.41 |

7.45E-05 |

|

10 |

1.5616 |

364.418151 |

1.46E+04 |

16.89 |

9.62E-05 |

|

|

5 |

1.5616 |

182.209075 |

1.39E+04 |

20.02 |

2.43E-04 |

|

|

1 |

1.5616 |

36.441815 |

1.13E+04 |

20.95 |

3.35E-04 |

|

|

0.5 |

1.5616 |

18.220908 |

1.05E+04 |

19.01 |

5.42E-04 |

|

|

0.1 |

1.5616 |

3.644182 |

0.88E+04 |

16.63 |

7.98E-04 |

|

|

21.1 |

25 |

-0.0089 |

24.49288 |

1.29E+04 |

17.02 |

4.82E-05 |

|

10 |

-0.0089 |

9.797155 |

1.05E+04 |

18.88 |

7.43E-05 |

|

|

5 |

-0.0089 |

4.898577 |

0.72E+04 |

19.63 |

9.54E-05 |

|

|

1 |

-0.0089 |

0.979715 |

0.66E+04 |

21.47 |

1.22E-04 |

|

|

0.5 |

-0.0089 |

0.489858 |

0.58E+04 |

19.25 |

3.88E-04 |

|

|

0.1 |

-0.0089 |

0.097972 |

0.49E+04 |

16.94 |

5.27E-04 |

|

|

25 |

25 |

-0.3503 |

11.159379 |

1.01E+04 |

17.09 |

2.58E-05 |

|

10 |

-0.3503 |

4.463751 |

8.62E+03 |

19.53 |

3.64E-05 |

|

|

5 |

-0.3503 |

2.231876 |

7.48E+03 |

20.70 |

4.34E-05 |

|

|

1 |

-0.3503 |

0.446375 |

5.19E+03 |

22.24 |

6.61E-05 |

|

|

0.5 |

-0.3503 |

0.223188 |

4.62E+03 |

17.98 |

7.49E-05 |

|

|

0.1 |

-0.3503 |

0.044638 |

3.38E+03 |

17.23 |

1.03E-04 |

|

|

45 |

25 |

-1.9696 |

0.268127 |

3.97E+03 |

21.14 |

1.09E-05 |

|

10 |

-1.9696 |

0.107251 |

3.48E+03 |

22.45 |

2.04E-05 |

|

|

5 |

-1.9696 |

0.053625 |

2.86E+03 |

24.16 |

3.00E-05 |

|

|

1 |

-1.9696 |

0.010725 |

1.92E+03 |

22.59 |

5.46E-05 |

|

|

0.5 |

-1.9696 |

0.005363 |

1.72E+03 |

18.14 |

6.24E-05 |

|

|

0.1 |

-1.9696 |

0.001073 |

1.45E+03 |

16.03 |

4.05E-06 |

|

|

60 |

25 |

-3.0564 |

0.021955 |

1.92E+03 |

21.07 |

5.19E-06 |

|

10 |

-3.0564 |

0.008782 |

1.70E+03 |

23.56 |

7.00E-06 |

|

|

5 |

-3.0564 |

0.004391 |

1.36E+03 |

26.49 |

1.39E-05 |

|

|

1 |

-3.0564 |

0.000878 |

8.43E+02 |

24.74 |

3.59E-05 |

|

|

0.5 |

-3.0564 |

0.000439 |

7.56E+02 |

23.80 |

4.31E-05 |

|

|

0.1 |

-3.0564 |

0.000088 |

6.70E+02 |

18.36 |

6.04E-05 |

Table 2 shows the results of shift factor, reduced frequency, dynamic modulus, phase angle and the recoverable strain for 0.5% HDPP asphalt mix.

Table 2. Results for 0.5% HDPPFR Asphalt

|

Temp. (°C) |

Frequency (Hz) |

Shift factor |

Reduced frequency (Hz) |

Dynamic modulus (MPa) |

Phase angle (deg) |

Recoverable strain (mm/mm) |

|

4.4 |

25 |

1.5616 |

911.045377 |

1.89E+04 |

20.50 |

8.57E-05 |

|

10 |

1.5616 |

364.418151 |

1.66E+04 |

22.46 |

1.11E-04 |

|

|

5 |

1.5616 |

182.209075 |

1.58E+04 |

23.97 |

2.79E-04 |

|

|

1 |

1.5616 |

36.441815 |

1.29E+04 |

25.86 |

3.85E-04 |

|

|

0.5 |

1.5616 |

18.220908 |

1.20E+04 |

25.28 |

6.23E-04 |

|

|

0.1 |

1.5616 |

3.644182 |

1.00E+04 |

22.12 |

9.18E-04 |

|

|

21.1 |

25 |

-0.0089 |

24.49288 |

1.39E+04 |

22.64 |

5.54E-05 |

|

10 |

-0.0089 |

9.797155 |

1.13E+04 |

25.11 |

8.54E-05 |

|

|

5 |

-0.0089 |

4.898577 |

7.78E+03 |

26.11 |

1.10E-04 |

|

|

1 |

-0.0089 |

0.979715 |

7.13E+03 |

27.56 |

1.40E-04 |

|

|

0.5 |

-0.0089 |

0.489858 |

6.26E+03 |

25.27 |

4.46E-04 |

|

|

0.1 |

-0.0089 |

0.097972 |

5.29E+03 |

22.53 |

6.06E-04 |

|

|

25 |

25 |

-0.3503 |

11.159379 |

1.06E+04 |

22.73 |

2.97E-05 |

|

10 |

-0.3503 |

4.463751 |

9.05E+03 |

25.97 |

4.19E-05 |

|

|

5 |

-0.3503 |

2.231876 |

7.85E+03 |

27.53 |

4.99E-05 |

|

|

1 |

-0.3503 |

0.446375 |

5.45E+03 |

30.58 |

7.60E-05 |

|

|

0.5 |

-0.3503 |

0.223188 |

4.85E+03 |

26.91 |

8.61E-05 |

|

|

0.1 |

-0.3503 |

0.044638 |

3.55E+03 |

22.92 |

1.18E-04 |

|

|

45 |

25 |

-1.9696 |

0.268127 |

4.09E+03 |

28.12 |

1.25E-05 |

|

10 |

-1.9696 |

0.107251 |

3.58E+03 |

29.86 |

2.35E-05 |

|

|

5 |

-1.9696 |

0.053625 |

2.95E+03 |

30.80 |

3.45E-05 |

|

|

1 |

-1.9696 |

0.010725 |

1.98E+03 |

32.70 |

6.28E-05 |

|

|

0.5 |

-1.9696 |

0.005363 |

1.77E+03 |

29.13 |

7.18E-05 |

|

|

0.1 |

-1.9696 |

0.001073 |

1.49E+03 |

21.32 |

4.66E-06 |

|

|

60 |

25 |

-3.0564 |

0.021955 |

1.95E+03 |

26.02 |

5.97E-06 |

|

10 |

-3.0564 |

0.008782 |

1.73E+03 |

33.99 |

8.05E-06 |

|

|

5 |

-3.0564 |

0.004391 |

1.38E+03 |

35.23 |

1.60E-05 |

|

|

1 |

-3.0564 |

0.000878 |

8.57E+02 |

30.24 |

4.13E-05 |

|

|

0.5 |

-3.0564 |

0.000439 |

7.69E+02 |

25.00 |

4.96E-05 |

|

|

0.1 |

-3.0564 |

0.000088 |

6.81E+02 |

23.76 |

6.95E-05 |

Table 3 is presentation of the results of shift factor, reduced frequency, dynamic modulus, phase angle and the recoverable strain for 1.0% HDPP asphalt mix.

Table 3. Results for 1.0% HDPPFR Asphalt

|

Temp. (°C) |

Frequency (Hz) |

Shift factor |

Reduced frequency (Hz) |

Dynamic modulus (MPa) |

Phase angle (deg) |

Recoverable strain (mm/mm) |

|

4.4 |

25 |

1.5616 |

911.045377 |

9.13E+03 |

29.12 |

6.85E-05 |

|

10 |

1.5616 |

364.418151 |

8.03E+03 |

31.92 |

8.85E-05 |

|

|

5 |

1.5616 |

182.209075 |

7.65E+03 |

32.06 |

2.24E-04 |

|

|

1 |

1.5616 |

36.441815 |

6.22E+03 |

39.60 |

3.08E-04 |

|

|

0.5 |

1.5616 |

18.220908 |

5.78E+03 |

35.93 |

4.99E-04 |

|

|

0.1 |

1.5616 |

3.644182 |

4.84E+03 |

31.43 |

7.34E-04 |

|

|

21.1 |

25 |

-0.0089 |

24.49288 |

6.84E+03 |

32.17 |

4.43E-05 |

|

10 |

-0.0089 |

9.797155 |

5.57E+03 |

35.68 |

6.84E-05 |

|

|

5 |

-0.0089 |

4.898577 |

3.82E+03 |

37.10 |

8.78E-05 |

|

|

1 |

-0.0089 |

0.979715 |

3.50E+03 |

40.58 |

1.12E-04 |

|

|

0.5 |

-0.0089 |

0.489858 |

3.07E+03 |

36.49 |

3.57E-04 |

|

|

0.1 |

-0.0089 |

0.097972 |

2.60E+03 |

32.02 |

4.85E-04 |

|

|

25 |

25 |

-0.3503 |

11.159379 |

5.35E+03 |

32.30 |

2.37E-05 |

|

10 |

-0.3503 |

4.463751 |

4.57E+03 |

36.91 |

3.35E-05 |

|

|

5 |

-0.3503 |

2.231876 |

3.96E+03 |

39.12 |

3.99E-05 |

|

|

1 |

-0.3503 |

0.446375 |

2.75E+03 |

44.03 |

6.08E-05 |

|

|

0.5 |

-0.3503 |

0.223188 |

2.45E+03 |

39.98 |

6.89E-05 |

|

|

0.1 |

-0.3503 |

0.044638 |

1.79E+03 |

32.56 |

9.48E-05 |

|

|

45 |

25 |

-1.9696 |

0.268127 |

2.02E+03 |

39.95 |

1.00E-05 |

|

10 |

-1.9696 |

0.107251 |

1.77E+03 |

42.43 |

1.88E-05 |

|

|

5 |

-1.9696 |

0.053625 |

1.46E+03 |

48.77 |

2.76E-05 |

|

|

1 |

-1.9696 |

0.010725 |

9.79E+02 |

46.48 |

5.02E-05 |

|

|

0.5 |

-1.9696 |

0.005363 |

8.77E+02 |

34.28 |

5.74E-05 |

|

|

0.1 |

-1.9696 |

0.001073 |

7.40E+02 |

30.30 |

3.73E-06 |

|

|

60 |

25 |

-3.0564 |

0.021955 |

9.79E+02 |

39.82 |

4.77E-06 |

|

10 |

-3.0564 |

0.008782 |

8.67E+02 |

48.31 |

6.44E-06 |

|

|

5 |

-3.0564 |

0.004391 |

6.94E+02 |

61.07 |

1.28E-05 |

|

|

1 |

-3.0564 |

0.000878 |

4.30E+02 |

52.98 |

3.30E-05 |

|

|

0.5 |

-3.0564 |

0.000439 |

3.86E+02 |

40.53 |

3.97E-05 |

|

|

0.1 |

-3.0564 |

0.000088 |

3.42E+02 |

33.92 |

5.56E-05 |

Table 4 shows the result of shift factor, reduced frequency, dynamic modulus, phase angle and the recoverable strain for 1.5% HDPP asphalt mix.

Table 4. Results 1.5% HDPPFR Asphalt

|

Temp. (°C) |

Frequency (Hz) |

Shift factor |

Reduced frequency (Hz) |

Dynamic modulus (MPa) |

Phase angle (deg) |

Recoverable strain (mm/mm) |

|

4.4 |

25 |

1.5616 |

911.045377 |

2.99E+03 |

41.61 |

6.33E-05 |

|

10 |

1.5616 |

364.418151 |

2.63E+03 |

45.60 |

8.18E-05 |

|

|

5 |

1.5616 |

182.209075 |

2.50E+03 |

48.65 |

2.07E-04 |

|

|

1 |

1.5616 |

36.441815 |

2.03E+03 |

53.57 |

2.85E-04 |

|

|

0.5 |

1.5616 |

18.220908 |

1.89E+03 |

50.33 |

4.61E-04 |

|

|

0.1 |

1.5616 |

3.644182 |

1.58E+03 |

42.90 |

6.78E-04 |

|

|

21.1 |

25 |

-0.0089 |

24.49288 |

2.19E+03 |

45.95 |

4.10E-05 |

|

10 |

-0.0089 |

9.797155 |

1.79E+03 |

53.98 |

6.32E-05 |

|

|

5 |

-0.0089 |

4.898577 |

1.22E+03 |

56.00 |

8.11E-05 |

|

|

1 |

-0.0089 |

0.979715 |

1.12E+03 |

57.97 |

1.04E-04 |

|

|

0.5 |

-0.0089 |

0.489858 |

9.86E+02 |

50.28 |

3.30E-04 |

|

|

0.1 |

-0.0089 |

0.097972 |

8.33E+02 |

44.74 |

4.48E-04 |

|

|

25 |

25 |

-0.3503 |

11.159379 |

1.62E+03 |

46.14 |

2.19E-05 |

|

10 |

-0.3503 |

4.463751 |

1.38E+03 |

52.73 |

3.09E-05 |

|

|

5 |

-0.3503 |

2.231876 |

1.20E+03 |

55.89 |

3.69E-05 |

|

|

1 |

-0.3503 |

0.446375 |

8.30E+02 |

62.05 |

5.62E-05 |

|

|

0.5 |

-0.3503 |

0.223188 |

7.39E+02 |

54.55 |

6.37E-05 |

|

|

0.1 |

-0.3503 |

0.044638 |

5.41E+02 |

46.52 |

8.76E-05 |

|

|

45 |

25 |

-1.9696 |

0.268127 |

5.96E+02 |

57.08 |

9.27E-06 |

|

10 |

-1.9696 |

0.107251 |

5.22E+02 |

60.62 |

1.73E-05 |

|

|

5 |

-1.9696 |

0.053625 |

4.29E+02 |

64.53 |

2.55E-05 |

|

|

1 |

-1.9696 |

0.010725 |

2.88E+02 |

66.39 |

4.64E-05 |

|

|

0.5 |

-1.9696 |

0.005363 |

2.58E+02 |

58.98 |

5.30E-05 |

|

|

0.1 |

-1.9696 |

0.001073 |

2.18E+02 |

46.28 |

3.44E-06 |

|

|

60 |

25 |

-3.0564 |

0.021955 |

3.00E+02 |

60.89 |

4.41E-06 |

|

10 |

-3.0564 |

0.008782 |

2.65E+02 |

69.01 |

5.95E-06 |

|

|

5 |

-3.0564 |

0.004391 |

2.12E+02 |

71.52 |

1.18E-05 |

|

|

1 |

-3.0564 |

0.000878 |

1.32E+02 |

65.40 |

3.05E-05 |

|

|

0.5 |

-3.0564 |

0.000439 |

1.18E+02 |

57.76 |

3.66E-05 |

|

|

0.1 |

-3.0564 |

0.000088 |

1.05E+02 |

50.17 |

5.13E-05 |

Discussion

Dynamic modulus and Phase angle

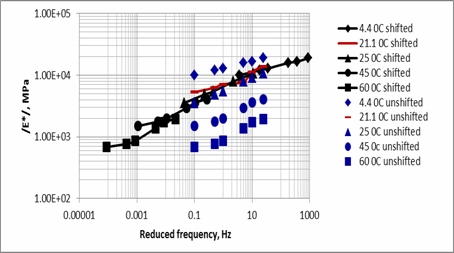

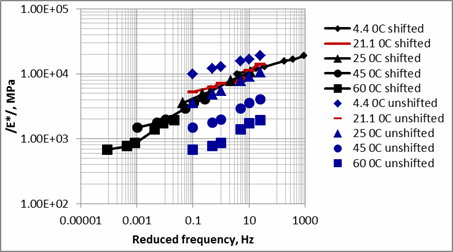

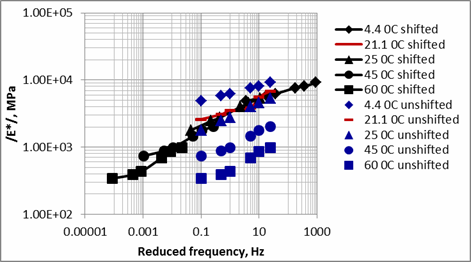

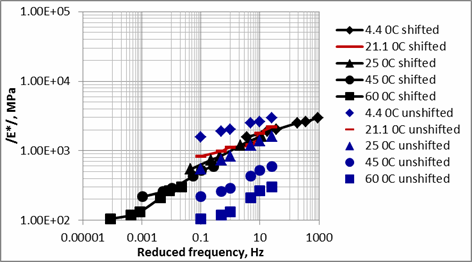

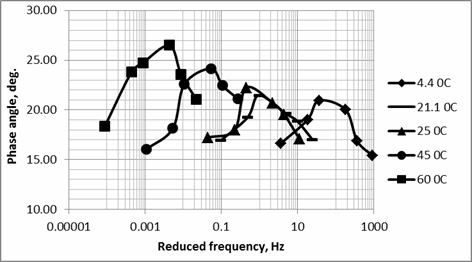

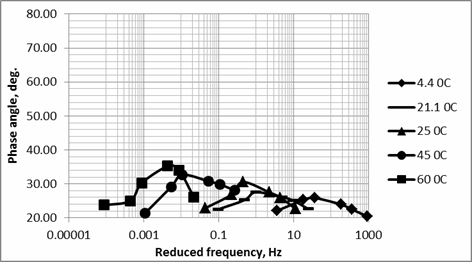

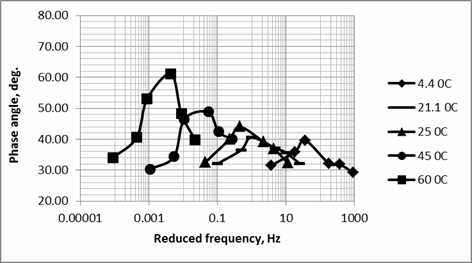

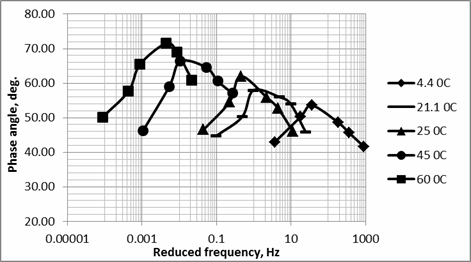

At low temperature and high frequency or strain rate, asphalt mix exhibits more elastic behavior, but as temperature increases followed by low strain rate, the viscous property becomes more prevalent. As the relationship between stress and strain becomes linear and is affected by temperature and frequency or time, the viscoelastic property of asphalt becomes linear too. Master curves were constructed to evaluate time-temperature superposition (TTS) and measure relationships between the physical quantities and dynamic modulus. Figures 3 to 11 show the TTS relationship for |E*| and φ.

· The value of |E*| increased from 0 to 0.5% HDPP because of bearable in void and improvement in the tensile property offered by fiber reinforcement. From 1.0 to 1.5% HDPP, the values of |E*| continued to drop because of increased void in the mix. The viscoelastic relationship agrees with the findings of [28].

Expectedly, the observed steady increase in φ are results of increasing voids and decreasing stiffness from 0 to 1.5% HDPP fiber asphalt in Figures 8 to 11. Higher ϕ results in poor mixes decrease in durability because of increased oxidation and tendency of permanent deformation failures occurring. The general viscoelastic behavior of asphalt indicates that the mixture is the most viscous as φ approaches 90° and as φ approaches 0° or infinity, the asphalt mixture behaves as an elastic solid at very low or very high frequencies. The observation agrees with the findings of [29].

Figure 3. Master curve for 0% HDPP

Figure

4. Master curve ![]() for 0.5% HDPP

for 0.5% HDPP

Figure

5. Master curve ![]() for 1.0% HDPP

for 1.0% HDPP

Figure

6. Master curve ![]() for 1.5% HDPP

for 1.5% HDPP

Figure 7. Master curve φ for 0% HDPP

Figure 8. Master curve φ for 0.5% HDPP

Figure 9. Master curve φ for 1.0% HDPP

Figure 10. Master curve φ for 1.5% HDPP

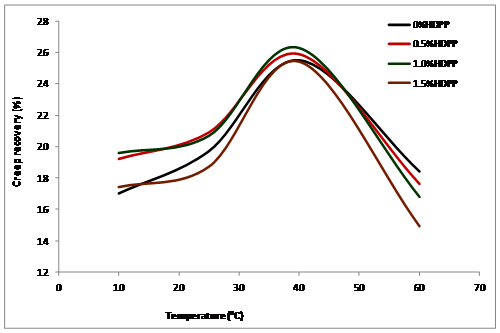

Recoverable strain

Strain recovery of asphalt mix has effects on visco-elasticity and life cycle [31]. While recovery strain are elastic or delayed elastic, irrecoverable strains are permanent deformations, viscoplastic and lead to rutting [32-34] observed that the manifestation of rutting are because of decrease in volume or densification and shear displacement that leads to shift of the material without volume change.

The mixes experienced recoverable strains (ε), which is a relief or resilience when cycles of stresses from goes away whereas irrecoverable strains are plastic and could lead to rutting or permanent deformation [35]. Both strains are slightly different from one cycle to another cycle due to the slight particle rearrangement and inter-particle motion which may exude binder film in some aggressive situations and under a low dynamic modulus which progresses as temperature and trafficking increases [36].

As shown in Figure 11, creep recovery increased with increasing temperature from 10 oC to 40oC as the rate of stress absorption, stress transfer and viscoelastic property increased when temperature increased ([37-39]). But beyond the optimum temperature of 40oC, the deformation flow of the mix is increased causing it to undergo plastic deformation.

Figures 11. Percentage creep recovery with temperature

Optimum creep recoveries were therefore attained at 40°C with marginal level of tolerance to sustain performances of the HDPP mixes up to 60oC even as the deformation increased. The percentage recovery is 26.3% which corresponds to 1.0% HDPP at optimum temperature of 40oC. Researchers like [33, 40] have observed the same positive trends of good creep recovery and improve pavement performance at temperature of 40°C. The recovery decreased with increasing HDPP content in the mix after the optimum result at 1.0% HDPP which could be attributed to increasing void entrainment. The strains are fairly close to the control as gains in tensile strength are counteracted by the void entrainment of two phase asphalt and reinforcing HDPP composite.

Conclusions

From the dynamic modulus evaluations, the following conclusions were drawn:

· The optimum /E*/ lies at 0.5% HDPP having about 12.5% increase in stiffness compared to the control (0% HDPP) for all temperature range from 4.4 – 60°C and frequencies of load cycles ranging between 25 – 0.1Hz.

· Static and dynamic properties are improved by 0.5% HDPP thereby rendering otherwise inherently brittle, low impact and tensile strength resistance material into superior crack resistance, enhanced ductility and distinctive post crack resilient behavior thereby delaying its propagation and increasing lifespan.

· Also, strain rate increased from 0 to 1.5% HDPP content and increased the value of φ because of increasing void and compressibility. The optimum in the case creep recovery lies at 1.0% HDPP; but 0.5% HDPP content equally produced strain within recoverable limit to withstand both serviceability and performance requirements for heavy traffic situation simulated.

Acknowledgements

We sincerely appreciate the contribution of Engr. Michael Esenwa, of McAsphalt, Ontario, Canada who facilitated access to their equipment and facilities used in carrying out the test.

References

1. Rais N. M., Endut I. R., Abdulwahab M. Y. and Abdullatif A., Dynamic modulus master curve construction using the modified MEPDG model, 2013, First international conference on artificial intelligence, modelling and simulation, IEEE computer society 2013, p. 184-188.

2. Epps A., Harvey J. T., Kim Y. R., Roque R., Structural Requirements of Bituminous Paving Mixtures. Millennium papers, Transportation Research Record, 500, 5th Street, Washington, DC USA. 2000; http://onlinepubs.trb.org/onlinepubs/millennium/00111.pdf (assessed 15/01/2015).

3. Zhao L. G. X., Zhao J. Research of the Low Temperature Crack Resistance for the Mineral Fibre Reinforced Asphalt Mixture, Journal of Applied Mechanics of Materials; 2011, 97-98. p. 172-175.

4. Brown E. R., Kandhal P. S., Zhang J. Performance Testing for Hot Mix Asphalt (Executive Summary), National Center for Asphalt Technology (NCAT) Report 01-05A, Auburn University, Alabama, USA. 2001, p. 1-17. http://www.eng.auburn.edu/center/ncat/reports/rep01-05.pdf (assessed 15/02/2015).

5. Zhao L. J. C., Wang S. Using Mineral Fibres to Improve Asphalt and Asphalt Mixture Behaviour. Traffic and Transport Studies, Kunming, China, 2010, p. 1352-1361.

6. Witczak M. W., Schwartz C. W., Von Quintus H., Interim Report NCHRP Project Report 9-19: Superpave Support and Performance Models Management. National Cooperative Highway Research Program, National Research Council, University of Maryland, U.S.A, 2003.

7. Bonaquist R., Christensen D. W., Stump W. NCHRP Report 513. Simple performance tester of superpave mix design. First-article development and evaluation, Transportation Research Board (TRB), Washington D. C., 2003, p. 3-54.

8. Whiteoak D., Read J., The Shell Bitumen Handbook. 5th Edition; Thomas Telford Publishing Ltd, 1 Heron Quay, London E14 4JD, U.K., 464 p. 2003.

9. Abdelhaq H. A., Construction of a Complex Shear Modulus Master Curve for Iraqi Asphalt Binder using a Modified Sigmoidal Fitting, International Journal of Scientific Engineering and Technology Research, 2015, 4(4), p. 0682-0690.

10. NCHRP Project 1-37A. Development of the 2002 Guide for the Design of New and Rehabilitated Pavement Structures, Phase 2, National Research Council, TRB, National Cooperative Highway Research Program, Washington D. C, U.S.A, 2004.

11. Witczak M. W., Kaloush K., Pellinen T., El-Basyouny M., Von Quintus H. Simple performance test for Superpave Mix Design, NCHRP Report 465, National Cooperative Highway Research Program, Transportation Research Board, Washington D.C., 2002, p. 1-105.

12. Overseas Road Note 19, A guide to the design of hot mix asphalt in tropical and sub-tropical countries, TRL Limited, Crowthorne, Berkshire, United Kingdom, 2002.

13. Zheng J. L., Guoping Q., Ronghua Y. Testing Thermal Viscoelastic Constitutive Relation of Asphalt Mixtures and its Mechanical Applications; Journal of Engineering Mechanics, 2008, 25(1), p. 34-41.

14. Sperling L. H., Introduction to physical polymer science. Lehigh University Bethlehem, Pennsylvania John Wiley & Sons, Inc., Hoboken, New Jersey. 2006; 4th Edn., p. 473-536.

15. Yue H., Roger N. B., Oliver H., A review of the use of recycled solid waste materials in asphalt pavements, Journal of Resources, Conservation & Recycling, 2007, 52, p. 58-73.

16. Romero P., Shenoy A, Standardized Procedure for Analysis of Dynamic Modulus |E*| Data to Predict Asphalt Pavement Distresses, Transportation Research Record 1789: Journal of the Transportation Board, 2002, p. 173-182.

17. Yusoff N. I. M., Chaillleux E., Airey G. D., A Comparative Study of the Influence of Shift Factor Equations on Master Curve Construction, International Journal of Pavement Resources Technology, 2011, 4, p. 324-336.

18. Soleimani A. Use of dynamic phase angle and complex modulus for the low temperature performance grading of asphalt cements, MSc Thesis in Engineering, Queen’s University, Kingston, Ontario, Canada, 2009.

19. Rowe G. M., Baumgardner G., Sharrock M., Functional Forms for Master Curve Analysis of Bituminous Materials. Proceedings of the 7th Int. RILEM Symposium on Advanced Testing and Characterization of Bituminous Materials, Rhodes, Greece (Book 1 Edited by Loizos, Partl, Scapas and Al-Qadi), 2010, p. 81-91.

20. Booshehrrian A., Mogawer W. S., Bonaquist R., How to construct an Asphalt Binder Master Curve and Assess the Degree of Blending between RAP and Virgin Binders. Journal of Materials in Civil Engineering, 2012, 25, p. 1813-1821.

21. Pellinen T. K., Asphalt Mix Master Curve Construction Using Sigmoidal Fitting Function with Nonlinear Least Squares Optimization Technique, 15th ASCE Engineering Mechanics Conference, Colombia University, New York, 2002.

22. Rowe G. M., Sharrock M. Alternate shift factor relationship for describing temperature dependency of viscoelastic behavior of asphalt materials. Transportation research record: Journal of the Transportation Research Board, 2011, 2207, p. 125-135.

23. Witczak M., Simple Performance Tests: Summary of Recommended Methods and Database, NCHRP Report 547, National Cooperative Highway Research Program, Washington, D.C., p. 2005.

24. Dougan C. E., Stephens J. E., Mahoney J., Hansen G., E* - dynamic modulus test protocol – problems and solutions, Connecticut Transportation Institue, University of Connecticut, Storrs, Connecticut, USA Report Number CT-SPR-0003084-F-03-3, 2003, p. 1-30.

25. Medani T. O., Huurman M., Constructing the stiffness master curves for asphalt mixes, Report 7-01-127-3, Delft University of Technology, Netherland, 2003.

26. ASTM D1559, Test Method for Resistance to Plastic Flow of Bituminous Mixtures using Marshall Apparatus, American Society for Testing Materials, Philadelphia, USA, 2004, Section 4 Vol.4.03.

27. AASHTO TP62-03, Standard Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt (HMA), Standard by American Association of State and Highway Transportation Officials, Virginia, U.S.A., 2005.

28. AASHTO 312-01, Preparing and Determining the Density of Hot-Mix Asphalt (HMA) Specimens by Means of the Superpave Gyratory Compactor, Standard Test Method for Transportation Materials and Methods of Sampling and Testing, Part II-Tests, 20th Edn, 2001.

29. Lu X., Soenen H., Redelius P., Rheological characterization of polymer modified bitumen, Annual Transactions of the Nordic Rheology Society, 2011, 19, available at: http://www.nynas.com/Global/Bitumen%20for%20paving%20applications/UK/Rheological%20Characterization%20of%20Polymer%20Modified%20Bitumens.pdf.

30. Christensen R. M., Theory of viscoelasticity, Dover Civil and Mechanical Engineering, Mineola, New York, U.S.A., Second Edition, 2003.

31. Geber R., Apkaryan A., Kulkov S., Gomez L. A., Linear viscoelastic properties of asphalt mastics using creep-recovery technique, Material Science and Engineering, 2014, 39(2), p. 5-11.

32. Elnasri M., Thom N., Airey G., Experimental study of binder-filler interaction using the modified multiple stress-strain creep recovery test. Transport Research Arena, Paris, 2014, p. 1-10.

33. Elnasri M., Airey G., Thom N., Experimental Investigation of Bitumen and Mastics under Shear Creep and Creep-Recovery Testing, Airfield and Highway Pavement 2013, Sustainable and Efficient Pavements, ASCE, 2013.

34. Shenoy A., Estimating the Unrecovered Strain during a Creep Recovery Test from the Material's Volumetric-flow Rate, International Journal of Pavement Engineering, 2002, 3(1), p. 29-34.

35. Dawson A. R., Pavement Foundations. Bituminous Pavements, Materials, Design and Evaluation, University of Nottingham, School of Civil Engineering, 2000.

36. Thom N. H., Airey G. D., Binder and Mixture Fatigue Study, Report to Nynas Bitumen, The University of Nottingham, U.K., 2006.

37. Yao H., You Z., Li L., Lee C. H., Wingard D., Yap Y. K., Shi X., Goh X., Rheological properties and chemical bonding of asphalt modified with nanosilica, ASCE Journal of Materials in Civil Engineering, 2013, 25(11), p. 1619-1630.

38. Mokhtari A., Moghadas-Nejad F., Mechanistic approach for fibre and polymer modified SMA mixtures, Constr. Build. Mater., 2012, 36, p. 381-390.

39. Khodaii A., Mehrara A., Evaluation of permanent deformation of unmodified and SBS modified asphalt mixtures using dynamic creep test, Constr. Build. Mater., 2009, 23, p. 2586-2592.

40. Moghaddam T. B., Soltani M., Karim M. R., Evaluation of permanent deformation characteristics of unmodified and Polyethylene Terephthalate modified asphalt mixtures using dynamic creep test, Elsevier Materials and Design, 2014, 53, p. 317-324.