Distillate yield improvement using a parabolic dish reflector coupled single slope basin solar still with thermal energy storage using beeswax

Aondoyila KUHE* and Alex Okibe EDEOJA

Department of Mechanical Engineering, University of Agriculture, Makurdi, Benue State, Nigeria

E-mails: amkuhe@uam.edu.ng; aoedeoja@gmail.com

* Corresponding author, phone: +234-8125125190

Received: January 3, 2016 / Accepted: July 17, 2016 / Published: July 31, 2016

Abstract

A single slope solar still, integrated with latent heat thermal energy storage system coupled to a parabolic concentrator was designed with the aim of improving productivity. 14 kg of beeswax was used as phase change material (PCM) between the absorber plate and the bottom of the still to keep the operating temperature of the still high enough to produce distilled water even during the sunset hours. The bottom of the still is covered by 0.2 m aluminum sheet painted black on the side facing the parabolic concentrator to help in absorbing solar radiation reflected from the parabolic concentrator and conducting same to the PCM. To determine the effect of PCM, a solar still without PCM was used to compare with the solar still with PCM. The temperature of water, air temperature, inner surface glass temperature and outer surface glass temperature were measured. Experimental results show that the effect of thermal storage in the parabolic concentrator-coupled single slope solar still increased the productivity by 62%.

Keywords

Solar still; Beeswax; Parabolic dish reflector; Distillate yield; Phase change material

Introduction

The performance of solar stills is generally expressed as the quantity of water produced by basin area in a day. The quantity of water produced by the solar still is affected by design, operational and ambient conditions. The ambient conditions cannot be controlled by humans as they are dependent on meteorological parameters. The design conditions which include assembly materials can be easily manipulated by humans to affect the production rate [1].

Distillate yield is often hindered by temporary temperature alternations caused by the intermittent availability of solar energy from the sun [2]. Latent heat thermal energy storage is an effective way to store thermal energy for heating water by energy received from sun. The storage of heat energy improves the performance of thermal systems and extends the output over a greater period [3]. Latent heat thermal energy storage system (LHTESS) using phase change materials (PCMs) is preferred to sensible heat storage (SHS) as an energy storage medium because of its high heat storage capacity, small unit size and isothermal behavior during charging and discharging [2]. Phase change materials (PCM) are able to change their state with addition or removal of heat at a particular temperature.

Improving the performance of conventional solar stills (CSS) using phase change material (PCM) as heat storage media in solar still have been previously studied. Tabrizi et al. [4] is studied two cascade solar stills constructed with and without latent heat thermal energy storage system (LHTESS). Paraffin wax was selected as the phase change material (PCM) which acts as a LHTESS. Thermal performances of the stills were compared on typical sunny and partially cloudy days. Results showed that the total productivity is nearly the same for both stills in a typical sunny day. However, for a partially cloudy day, the still with LHTESS has a significantly higher productivity. Referring to [5], the authors developed a theoretical model for a still with and without phase change material (PCM). They concluded that the daily productivity of the still with and without the PCM was 6.7 and 5.1 kg/m2/day respectively. The results showed that the productivity of the still with PCM was theoretically 31% higher than that of without PCM. Murugave et al. [6] showed the effect of minimum depth of water with different storage materials in the basin. The performance of the solar still was compared with different types of energy storing materials like quartzite rock, washed stone, cement block pieces, red brick pieces and iron scraps. It was observed that, the still with 3/4 in. sized quartzite rock is the effective basin material. The transient performance of a stepped solar still with built-in latent heat thermal energy storage was studied by [7]. He concluded that the still has an efficiency of 57% and the total yield is about 4.6 L/day/m2. A mathematical model for a single basin-single slope solar still with and without PCM under the basin liner of the still was presented by [8]; numerical calculations were carried out using stearic acid as a PCM, on typical summer and winter days. The results of the study showed a productivity of 9.005 (kg/m2 day) with a daily efficiency of 85.3% has been obtained compared to 4.998 (kg/m2 day) when the still was used without the PCM. A concentrator-coupled hemispherical single-slope solar still with and without phase change material (PCM) were studied experimentally by [3]. Results indicate that the effect of thermal storage in the concentrator-coupled hemispherical basin solar still increases the productivity by 26%.

In this paper, a parabolic reflector-coupled single slope basin solar still is integrated with beeswax as a PCM beneath the basin liner of the still. Because of the high melting point of beeswax, heat from the parabolic dish reflector apart from direct solar radiation was used. The distillate yields, with and without PCM effect are reported.

Material and method

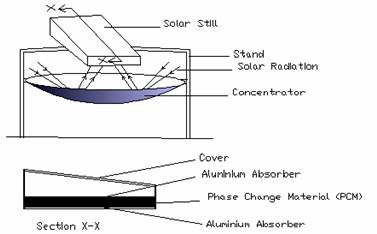

A schematic and pictorial diagram of the parabolic reflector dish integrated solar still with phase change material (during the still assembly itself the PCM is placed in between the basin liner and bottom of the still) as a heat storage medium is shown in Figures 1 and 2.

Figure 1. Schematic diagram of parabolic reflector dish coupled single slope basin solar still

Figure 2. Image of the parabolic reflector dish coupled single slope basin solar still

The basin area is 0.3 m2, fabricated from an aluminum sheet of thickness 0.2 cm, with the side facing the sun painted black. A space of 3 cm is left between the basin liner (absorber) and the bottom cover. This gap is loaded with the 14 kg of PCM. Waste beeswax which is a by-product of the local honey processing industry is used as the PCM because of its low cost, wide availability and stability in the working range. The bottom of the solar still is then covered with aluminum sheet of thickness 0.2 cm painted black on the face towards the parabolic concentrator. Table 1 summarizes the thermo-physical properties of beeswax (Ravi Ramnanan-Sing, 2012).

Table 1. Thermo-chemical properties of beeswax [10]

|

Material properties |

Beeswax |

|

Melting Temperature, °C |

61-8 |

|

Latent heat of fusion, kJ/kg |

1.7×105 |

|

Solid density, kg/m3 |

970 |

|

Thermal conductivity, W/m °C |

2.5×10-3 |

|

Specific heat capacity, kJ/kg °C |

3.4 |

The sides of the basin are insulated by 3 cm layer of rock wool (thermal conductivity of 0.038 W/m2 K) in a wooden frame of 1 cm thickness to prevent heat losses. The cover of the still is made up of 0.3 cm thick simple window glass, making an angle of 27.9o with the horizontal. The Optimum slope of inclination for Makurdi city was calculated using angle of solar declination (δ), number of days, latitude at test site, and angle of incidence from the following equation [9], where slope of collector (β) is calculated, and where = Latitude at test site = 7.7° N: β = Π -δ.

Experimental parameters used in the experimental work are shown in Table 2.

Table 2. Experimental parameters

|

Parameters |

Symbol |

Value |

|

Transmittance of cover |

τc |

88% |

|

Emissivity of cover |

εc |

0.98 |

|

Wind velocity |

V |

0.8 m/s |

|

Density of water |

ρ |

989 kg/m3 |

|

Latent heat of vaporization |

hfg |

2,463 kJ/kg |

|

Declination angle |

δ |

20.2° |

|

Latitude |

φ |

7.7° |

This optimum angle is about 27.9° for Makurdi which is located in the middle belt region of Nigeria. The fresh water is collected in an aluminum channel fixed at the lower end of the glass cover. Various temperatures like ambient (Tamb), water (Tw), air (Ta), and condensing glass cover inner–outer surfaces (Tig and Tog) were recorded hourly between the hours of 9:00 am-5:00 pm using K-type thermocouples.

Table 3 summarizes accuracies and error percentage of various measuring instruments used in the experiment. The solar radiation transmitted through the glass cover and basin water is absorbed by the basin liner. Part of the thermal energy is transferred by convection to the basin water and the remaining portion is transferred by conduction to the PCM beneath the basin liner.

Table 3. Accuracies, range and errors of measuring instruments used

|

S/No. |

Instrument |

Accuracy |

Range |

% Error |

|

1 |

Solarimeter |

±1W/m2 |

0-2500W/m2 |

2.5 |

|

2 |

Digital thermometer |

±1°C |

0-250°C |

0.5 |

|

3 |

K-type thermocouples |

±0.1°C |

0-300°C |

0.5 |

|

4 |

Anemometer |

±0.1m/s |

0-20 m/s |

5 |

|

5 |

Measuring jar |

±10ml |

0-1000 ml |

10 |

The parabolic solar concentrator is used to heat the bottom cover of the solar still, heat is transmitted by conduction to the PCM, this heat is first stored as sensible heat as beeswax temperature increases, then heat is stored as latent heat during the change of phase of the beeswax. This process is the charging stage, while the reverse is called the discharge stage.

The combined effect of heating from above and below the solar still melts the beeswax faster and increases the energy available to the water in the still basin thereby enhancing still productivity. As the sun starts setting, the amount of solar radiation decreases, but the sensible discharge period is increased due to heat from the parabolic dish concentrator, as the solar radiation decreases.

The beeswax is kept molten by the heat from the parabolic dish concentrator and will continue to transfer heat to the basin liner and from the latter to the basin water till the PCM completely solidified when the sun sets. As the beeswax solidifies latent heat is released. In other words, the beeswax will act as a heat source for the basin water during low intensity solar radiation periods.

Results

The productivity of a solar still is dependent on meteorological conditions of a place like solar radiation, ambient temperature etc.

Figure 3 shows the variation of solar radiation and ambient temperature with time on 26/1/2015. Insolation is measured in the range of 580 W/m2 to 899 W/m2, insolation gradually increases from 8:00 am to 13:00 pm as the sun rises and then decreases as the sun sets. The ambient temperature is in the range of 27.3°C to 39.3°C.

Figure 3. Hourly variation of solar radiation and ambient temperature with respect to time

The variation of water temperature, air temperature, inner cover temperature and outer cover temperature with time for parabolic concentrator-coupled single slope basin solar still with beewax is shown in Figure 4.

Figure 4. Hourly variation of solar radiation and ambient temperature with respect to time

The maximum water temperature observed was 86°C at 13:00 pm. Similarly the maximum still air temperature of 80°C was measured, while the inner and outer glass temperatures were in the range of 39-73°C and 32-63°C, respectively.

Figure 5 shows the variation of water temperature, still air temperature, inner glass temperature, and outer glass temperature with respect to time for parabolic dish concentrator-coupled single slope basin solar still without PCM.

Figure 5 Hourly variation of temperature in concentrator coupled hemispherical basin solar still without PCM

The maximum water temperature observed was 76°C. Similarly the maximum air temperature of 69°C was measured, while the inner and outer glass temperatures were in the range of 32–67°C and 30–60°C, respectively.

Figure 6 shows the distillate yield with respect to time. The maximum output collected for parabolic dish concentrator-coupled single slope basin solar still with beeswax was 5243 ml/m2/day, and 3240 ml/m2/day for the solar still configuration without beeswax.

Figure 6. Distillate yield with respect to time

Discussion

The hourly productivity with the beeswax is much higher than without the beeswax during sunrise which is characterized by increasing solar intensities. This behavior is unexpected because the PCM under the basin liner absorb heat from the liner. But in the current configuration, the parabolic dish provides concentrated heat flux to the beeswax via the basin liner thereby increasing the basin water temperature as well as the productivity throughout the day and in the evening.

The beeswax is melted in the morning hours due to the high intensity of solar radiation from the parabolic concentrator. It melts entirely during the charging phase from 10:00 to 11:00 h.

The beeswax is kept molten by the intensity of the radiation from the parabolic concentrator even with a decrease in the ambient temperature and solar intensity. Subsequently, with a further decrease in solar intensity towards sunset, the beeswax begins to solidify, releasing latent heat into water in the still basin.

The still with beeswax yields larger amounts of distilled water than the still without beeswax because of the higher operating temperature gradient between the basin water and inner glass temperature. This high operating temperature is obtained because the stored heat from the beeswax is transferred by conduction through the basin liner to evaporate the water at a high temperature.

Furthermore, the increase in temperature noticed in the still at 16:00 to 17:00 h is due to the effect of heat released by the PCM during the discharge stage of the beeswax heat storage system. The productivity of the concentrator coupled single slope single basin solar still with beeswax was approximately 62% higher than the concentrator coupled single slope single basin solar still without beeswax.

Conclusions

Experiments have been conducted to enhance distillate output of solar still. The performance of parabolic dish concentrator coupled single slope single basin solar still without beeswax under the basin liner was compared with that parabolic dish reflector coupled single slope single basin solar still with beeswax under the basin liner. It was observed that, on a normal day, the average daily productivity of the parabolic concentrator coupled single slope single basin solar still can be increased by 62% with beeswax under basin liner of solar still. The higher temperature difference observed between the basin water and inner glass temperature is due to more heat available to the basin water. It is recommended to integrate latent heat energy storage system in solar stills to further enhance their productivity.

References

1. Manokar U. A., Muragarel K. K., Esakkimuthu G., Different parameters affecting the rate of evaporation and condensation on passive solar still- A review, Renewable and Sustainable Energy Reviews, 2014, 38, p. 300-322

2. Reddy R. M., Nalhasamy N., Hariprasad T., Reddy H. R., Reddy R. G., Solar energy based thermal energy storage system using phase change materials, International Journal of Renewable Energy Technology, 2012, 3(9), p. 11-23.

3. Arunkumar T., Denkenberger D., Ahsan A., Jayaprakash R., The augmentation of distillate yield by using concentrator coupled solar still with phase change material, Desalination, 2013, 314, p. 189-192.

4. Tabrizi F. F., Dashtban M., Moghaddam H., Experimental investigation of weir-type cascade solar still build-in latent heat thermal energy storage system, Desalination, 2010, 260, p. 248-253.

5. Dashtban M., Tabrizi F. F., Thermal analysis of a weir-type cascade solar still integrated with PCM storage, Desalination, 2011, 279, p. 415-422.

6. Murugavel K. K., Sivakumar S., Ahamed J. R., Chockalingam K. S. K., Sridhar, K., Single basin double slope solar still with minimum basin depth and energy storing materials, Appl. Energy, 2010, 87, p. 514-523.

7. Radhwan A. M., Transient performance of a stepped solar still with built-in latent heat thermal energy storage, Desalination, 2004, 171, p. 61-76.

8. El-Sebaii A. A., Al-Ghamdi A. A., Al-Hazmi F. S., Faidah A. S., Thermal performance of a single basin solar still with PCM as a storage medium, Applied Energy, 2009, 86, p. 1187-1195.

9. Brenidorfer B., Kennedy L., Oswin Bateman C. O., Trim D. S., Solar dryer; their role in post-harvest processing, Commonwealth Secretariat Marlborough house, London, 1985, p. 237.

10. Ramnanan-Singh R., Formulation & Thermophysical Analysis of a Beeswax Microemulsion & The Experimental Calculation of its Heat Transfer Coefficient, Master of Engineering (Mechanical) thesis submitted to The City College of New York of the City University of New York, 2010.