Engineering, Environment

Reliability estimate of unconfined compressive strength of black cotton soil stabilized with cement and quarry dust

John Engbonye SANI1, Dayo Oluwatoyin AKANBI2, Godwin Lazhi YISA2 and Hadiza Ibrahim HAMIDU3

1Department of Civil Engineering, Nigeria Defence Academy, PMB 2109Kaduna State, Nigeria.

2Nigeria Building and Road Research Institute, Ota, Ogun State, Nigeria.

3Department of Civil Engineering, Kaduna Polytechnics, Kaduna, Nigeria.

E-mail: 1sejohn2000@yahoo.com; 2akanbidahyour@yahoo.com; 2godwinyisa@gmail.com; 3hadizahamidu@yahoo.com

Corresponding author: +2348038752773

Received: September 30, 2016 / Accepted: June 14, 2017/ Published: June 30, 2017

Abstract

Reliability estimates of unconfined compressive strength values from laboratory results for specimens compacted at British Standard Light (BSL)for compacted quarry dust treated black cotton soil using cement for road sub – base material was developed by incorporating data obtained from Unconfined compressive strength (UCS) test gotten from the laboratory test to produce a predictive model. Data obtained were incorporated into a FORTRAN-based first-order reliability program to obtain reliability index values. Variable factors such as water content relative to optimum (WRO), hydraulic modulus (HM), quarry dust (QD), cement (C), Tri-Calcium silicate (C3S), Di-calcium silicate (C2S), Tri-Calcium Aluminate (C3A), and maximum dry density (MDD) produced acceptable safety index value of1.0and they were achieved at coefficient of variation (COV) ranges of 10-100%. Observed trends indicate that WRO, C3S, C2S and MDD are greatly influenced by the COV and therefore must be strictly controlled in QD/C treated black cotton soil for use as sub-base material in road pavements. Stochastically, British Standard light (BSL) can be used to model the 7 days unconfined compressive strength of compacted quarry dust/cement treated black cotton soil as a sub-base material for road pavement at all coefficient of variation (COV) range 10 – 100% because the safety index obtained are higher than the acceptable 1.0 value.

Keywords

Quarry Dust; Cement; Black Cotton Soil; Reliability Index; Unconfined Compressive Strength

Introduction

A reliability estimate of an engineering system is defined as the confidence on its ability to fulfill its design purpose for some time-period [1]. Reliability estimates are based on the probability theories which provide the fundamental basis for its measurement. The reliability of a structure can be viewed as the probability of its satisfactory performance, according to some performance functions, for a specific service and subjected to extreme conditions within a stated time-period. Researchers like [2] and [3] reported that Reliability-based design has been in used to reduce the uncertainties in geotechnical engineering during design and construction in terms of the variable nature of soil and rock properties and other in situ conditions. Due to the upcoming uncertainties about the reliability of design, construction methods, the costs and benefits of proposed design strategies, a reliability estimate is applied.

The design and construction of civil engineering structures on expansive soils poses a serious challenge as the frequency of road pavement failures have been of great concern to road engineers in Nigeria[6]. Structures sitting on expansive soils (black cotton soil) suffers from both structurally and non-structurally damages due to the alternate expansion and contraction of the soil due to moisture changes [6]. Sub-grade soil is an integral part of pavement structures by supporting the pavement hence must give adequate support and stability under adverse loading conditions [7]. In Nigeria black cotton soils (expansive clays) are typically found in low lying areas of North eastern states of Gombe, Borno, Yobe, Adamawa, Taraba, and Bauchi States. The soils according to [7] occurs in discontinuous stretches as superficial deposits; usually not more than 2m thick.

Quarry dust treated black cotton soil with cement recorded great improvement in terms of strength gain [7]. The peak value of the treated soil at British standard light (BSL) compactive efforts falls short of 1710 kN/m2 specified by [8] for base material however the data obtained was used to obtain a regression equation which was incorporated into the first order reliability method (FORM) to see the effect on the safety index with variation in the strength parameter.

Strength is one of the major material properties of BCS that can be significantly affected by variability in composition and admixtures. Engineering analyses and designs require the application of probabilistic methods as deterministic approaches do not rigorously account for these uncertainties. Probability theory has been widely accepted and used in engineering. The application of probability theory to engineering analysis requires the knowledge of some statistical attributes of the relevant random variables such as their mean values and standard deviations [10]. One of such probabilistic methods is reliability analysis which has been used in geoenvironmental engineering [4]. Reliability analysis provides a frame work for establishing appropriate factors of safety and other design targets and leads to a better appreciation of the relative importance of uncertainties in different parameters [11]. Thus, this study was aimed at using Reliability analysis to assess the suitability of compacted quarry dust treated black cotton soil admixed with cement on strength properties of the soil.

Materials and methods

The Black cotton soil used for this study was collected at a depth of 1.5 meters from a burrow pit at Dadin-Kowa (10⁰19′19″N (latitude) and 11⁰28′54″S (longitude)) a distance of 1.5Km to Dadin-Kowa dam in Yamaltu Local Government area of Gombe State in Nigeria.

The quarry dust as the name implies, is a dust from quarry stones [8]. Quarry waste, dust or fines are used interchangeably [6]. It was obtained from a construction company quarry site along the Federal Polytechnic road in Bauchi. Ordinary Portland cement (Dangote) was also used in the stabilization.

Reliability Index

Another measure of the adequacy of an engineering design is the reliability index, defined as Eq. (1):

![]() (1)

(1)

This can be interpreted as the number of sigma units (the number of standard deviation d) between the mean values of the safety margin, Eq. (2):

E(s) = μ (2)

and its critical value, Eq. (3):

S= O (3)

The reliability index of a system, denoted by β is defined as the ratio between the mean and standard deviation of the safety margin of the system.

By definition, the reliability index is the reciprocal of the coefficient of variation of the safety margin, that is β = I/Vs[12].

Concept of First – Order Reliability Method (FORM)

The probabilistic and deterministic approaches to design differ in principle. Deterministic design is based on total ‘discounting’ of the contingency of failure. Design problems involve element of uncertainty; unpredictability of randomness. Probabilistic design is concerned with the probability that the structure will realize the functions assigned to it [12].

If r is the strength capacity and s the compositional effect(s) of a system which are random variables, the main objective of reliability analysis of any system or component is to ensure that r is never exceeded by s. In practice, r and s are usually functions of different basic variables. In order to investigate the effect of the variables on the performance of the system, a limit state equation in terms of the basic design variable is required [12].

This limit state equation is referred to as the performance or state function and expressed as, Eq. (4):

g(t) = g(x1, x2….xn) = r – s (4)

Where: x1 for i = 1, 2, 3, …, n, represent the basic design variables.

The limit state of the system can then be expressed as, Eq. (5):

G(t) - 0 (5)

Reliability calculations provide a means of evaluating the combined effects of uncertainties and a mean of distinguishing between conditions where uncertainties are particularly high or low. In design evaluation involving the selection of a value for a soil parameter to be used for geotechnical analysis, reliability analysis, which involves the application of probabilistic concepts, is suitable for taking care of uncertainties [13]. Thus, strength in term of unconfined compressive strength (USC) and California bearing ratio (CBR) are taken to be the basic parameter for design of sub base or sub grade materials.

Soil reliability can be estimated from eq. (6) if the type of probability distribution function for Strength and its statistical parameters (mean, standard deviation, variance, etc.) are known. This is also possible only with the probability of survival as given in Eq. (6):

![]() (6)

(6)

Where: ![]() - probability of

survival and

- probability of

survival and ![]() = probability of

failure.

= probability of

failure.

In the reliability analysis of compacted road pavement structure material, failure would occur when the 7 days UCS is less than the minimum value of 1710 kN/m2 specified by [8], for sub base during its service period or design life. The probability of failure (Pf) can then be formulated as, Eq. (7):

![]() (7)

(7)

Where: ![]() - expected strength;

- expected strength; ![]() - specified regulatory minimum

strength; WRO - water with respect to optimum; HM - hydraulic modulus; C –

cement; QD - quarry dust; C3S - Tri-Calcium Silicate; C2S

- Di-Calcium Silicate; C3A - Tri - Calcium Aluminate; MDD - maximum dry

density.

- specified regulatory minimum

strength; WRO - water with respect to optimum; HM - hydraulic modulus; C –

cement; QD - quarry dust; C3S - Tri-Calcium Silicate; C2S

- Di-Calcium Silicate; C3A - Tri - Calcium Aluminate; MDD - maximum dry

density.

Which are parameters affecting the strength and are used in predicting strength values based on laboratory results and compound formations contents based on admixture combination ratio.

The results of all laboratory experiments on strength and the parameters associated with strength were measured during the laboratory work. The various parameters measured include the following unconfined compressive strength UCS, water content with respect to optimum (WRO), hydraulic modulus HM, Cement C, Quarry Dust QD, Tri-Calcium Silicate C3S, Di-Calcium Silicate C2S, Tri-calcium Aluminate C3A, maximum dry density MDD. These results were used to run a regression model for predicting laboratory UCS results. The statistical analyses were carried out using the tools of analysis Mini-tab R15 software and the regression equation obtained for unconfined compressive strength is given in equation (8) bellow.

UCS (7) = - 13638 - 163 WRO + 298 HM + 93.6 Cement - 54.9 Quarry Dust - 16.8 C3S - 15.1 C2S - 10.7 C3A + 11089 MDD (8)

Reliability analysis is intended to assess the suitability of compacted Quarry dust treated black cotton soil with Cement strength characteristic for use as a sub base material. This becomes necessary due to the variability that might exist from black cotton soil obtained from one location to another and the compositional content of the additives. The statistical characteristics of the relevant black cotton soil – quarry dust – cement as well as physical properties of their probability distribution functions types were established.

The relevant statistical properties for black cotton soil – quarry dust – cement mixtures were then incorporated into FORTRAN programs for a field based predictive model in order to evaluate reliability levels and to predict UCS using the ‘first order reliability methods’ version 5.0 (FORM 5) [14]. The input data for the reliability analysis from the laboratory strength results are shown in Table. 1.

Results and discussion

A database was compiled by extracting data on Quarry Dust stabilized black cotton soil using cement from the laboratory test results of unpublished literature [7]. The statistical characteristics of the material composition and compaction variables for the black cotton soil are shown in Table 1.

Table.1. Input data for reliability based design for nine independent variable using FORM 5 from laboratory measured strength

|

S/No |

Variables |

Distribution type |

Mean E(x) |

Standard Deviation S(x) |

Coefficient of Variation COV (%) |

|

1 |

UCS |

Lognormal |

6.02E2 |

3.99E2 |

66.36 |

|

2 |

WRO |

Lognormal |

1.93E1 |

0.928E-1 |

4.82 |

|

3 |

HM |

Lognormal |

1.83E-1 |

1.23E0 |

147.5 |

|

4 |

C |

Normal |

3.0E0 |

2.294E0 |

76.47 |

|

5 |

QD |

Normal |

1.0E1 |

7.25E0 |

72.5 |

|

6 |

C3S |

Lognormal |

3.20E2 |

2.79E2 |

87.26 |

|

7 |

C2S |

Lognormal |

3.74E2 |

2.75E2 |

73.47 |

|

8 |

C3A |

Lognormal |

2.22E1 |

1.54E1 |

69.27 |

|

9 |

MDD |

Lognormal |

1.62E0 |

4.63E-2 |

2.87 |

Where: UCS - unconfined compressive strength; WRO - water content with respect to optimum; HM - hydraulic modulus; C – cement; QD - quarry dust; C3S - Tri-Calcium Silicate gotten; C2S - Di-Calcium Silicate; C3A - Tri - Calcium Aluminate; Mean E(x) - the laboratory test result; Standard Deviation S(x) = Mean E(x) x Coefficient of Variation COV (%)

![]()

![]()

![]()

Unconfined Compressive Strength

Effect of Strength on Reliability Index

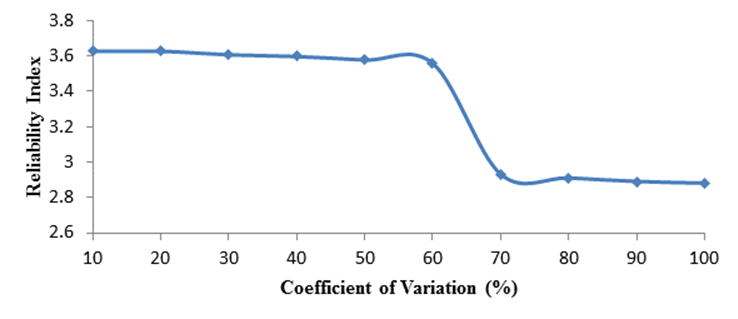

The effect of unconfined compressive strength on reliability index as the coefficient of variation is varied when computed with a minimum value of 1710 kN/m2 specified by [8] is shown in Figure 1.

Figure 1. Variation of reliability index with coefficient of variation for 7days unconfined compressive strength

Strength produced a decreasing relationship with coefficient of variation (COV) in the ranges 10-100%, but a sharp drop was recorded at 60% coefficient of variation. Safety index varied considerably which is an indication that variability of strength has drastic influence on the safety index especially above 60 % COV. As COV increased from 10-100%, β value decreased from 3.63 to 2.88.Similar trend of decreasing safety index as COV increases is reported by [16-17].

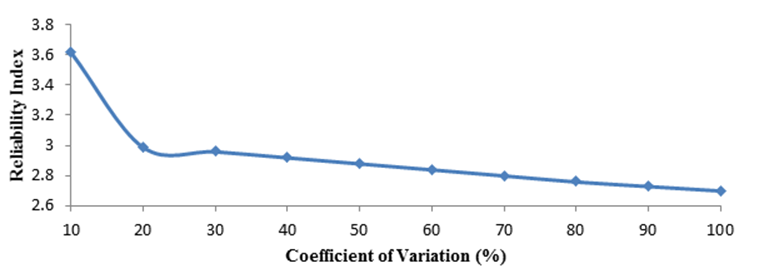

Effect of Water Content Relative to Optimum on Reliability Index on the 7 days unconfined compressive strength

The effect of water content relative to optimum on reliability index as the coefficient of variation is varied is shown in Figure 2.

Figure 2. Variation of reliability index with coefficient of variation for water content relative to optimum

Water content relative to optimum produced a linear decreasing relationship with coefficient of variation in the ranges 10-100% with a sharp decrease between 10 – 20 % COV. Safety index varied considerably which is an indication that variability of WRO has drastic influence on the safety index especially within 10 – 20 % COV. As COV increased from 10-100%, β value decreased from 3.62 – 2.70.

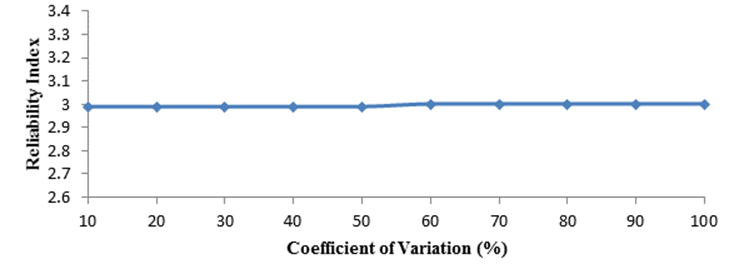

Effect of Hydraulic Modulus on Reliability Index on the 7 days unconfined compressive strength

The effect of hydraulic modulus on reliability index as the coefficient of variation is varied is shown in Figure 3.

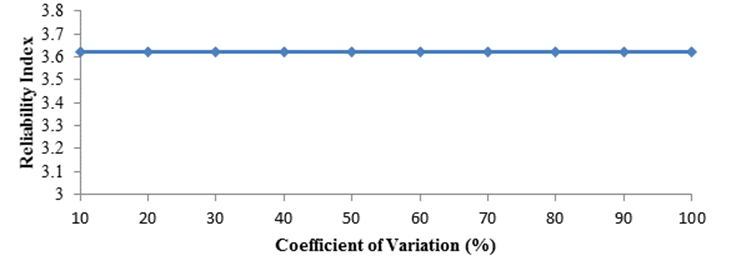

Figure 3. Variation of reliability index with coefficient of variation for hydraulic modulus

Hydraulic modulus produced a linear relationship with coefficient of variation in the ranges 10-100%, in which the safety index remain constant. This is an indication that variability of hydraulic modulus has no drastic influence on the safety index.

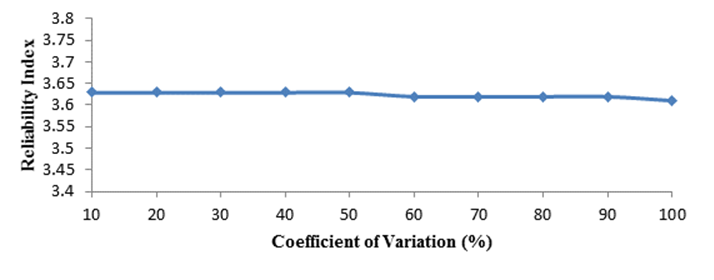

Effect of Quarry Dust Content on Reliability Index on the 7 days unconfined compressive strength

The effect of quarry dust content on reliability index as the coefficient of variation is varied is shown in Figure 4.

Figure 4. Variation of reliability index with coefficient of variation for quarry dust

Quarry dust produced a linear relationship with coefficient of variation in the ranges 10-100%, in which the safety index remain constant. This is an indication that variability of quarry dust has no drastic influence on the safety index.

Effect of Cement Content on Reliability Index on the 7 days unconfined compressive strength

The effect of cement content on reliability index as the coefficient of variation is varied is shown in Figure 5.

Figure 5. Variation of reliability index with coefficient of variation for cement

Cement produced a linear relationship with coefficient of variation in the ranges 10-100%, in which the safety index remain constant. This is an indication that variability of cement has no drastic influence on the safety index.

Effect of Tri-calcium silicate on Reliability Index on the 7 days unconfined compressive strength

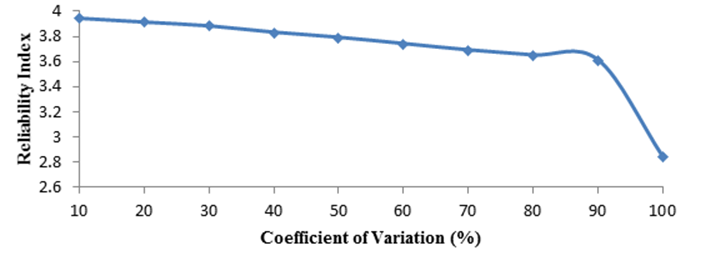

The effect of Tri-calcium silicate content on reliability index as the coefficient of variation is varied is shown in Figure 6.

Figure 6. Variation of reliability index with coefficient of variation for Tri-Calcium silicate

Tri-calcium silicate produced a decreasing relationship with coefficient of variation (COV) in the ranges 10-100%, but a sharp drop was recorded at 90 % coefficient of variation. Safety index varied considerably which is an indication that variability of Tri-calcium silicate has drastic influence on the safety index especially above 90 % COV. As COV increased from 10-100%, β value decreased from 3.94 to 2.84.

Effect of Di-calcium silicate on Reliability Index on the 7 days unconfined compressive strength

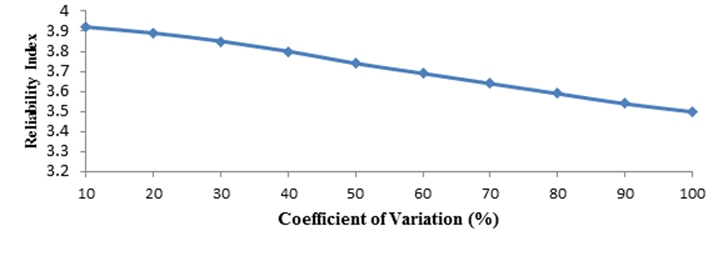

The effect of Di-Calcium silicate content on reliability index as the coefficient of variation is varied is shown in Figure 7.

Figure 7. Variation of reliability index with coefficient of variation for Di-Calcium silicate

Di-calcium silicate produced a decreasing relationship with coefficient of variation (COV) in the ranges 10-100%, Safety index varied considerably which is an indication that variability of strength has drastic influence on the safety index. As COV increased from 10-100%, β value decreased from 3.92 to 3.5.

Effect of Tri-calcium Aluminate on Reliability Index on the 7 days unconfined compressive strength

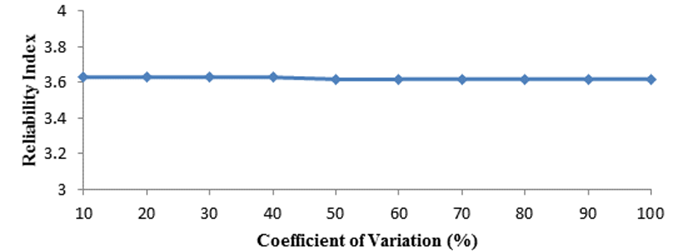

The effect of Tri-calcium Aluminate content on reliability index as the coefficient of variation is varied is shown in Figure 8.

Figure 8. Variation of reliability index with coefficient of variation for Tri-Calcium Aluminate

Tri-calcium aluminate produced a linear relationship with coefficient of variation in the ranges 10-100%, in which the safety index remain constant. This is an indication that variability of Tri-calcium aluminate has no drastic influence on the safety index.

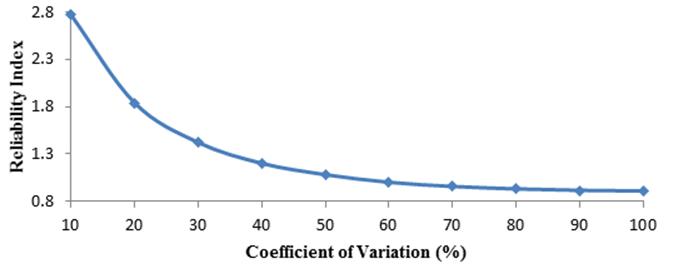

Effect of Maximum Dry Density on Reliability Index on the 7 days unconfined compressive strength

The effect of maximum dry density on reliability index as the coefficient of variation is varied is shown in Figure 9.

Figure 9. Variation of reliability index with coefficient of variation for maximum dry density

Maximum dry density produced a decreasing relationship with coefficient of variation (COV) in the ranges 10-100%. Safety index varied considerably which is an indication that variability of strength has drastic influence on the safety index especially within 10 – 30 % COV. As COV increased from 10-100%, β value decreased from 2.77 to 0.907.

Statistical Significance of Safety Index Values

Statistical analysis of all the results obtained for the parameters (UCS, W.R.O., HM, QD, C, C3S, C2S, C3A and MDD) under consideration using the one-way analysis of variance (ANOVA) produced statistically significant (SS) results as shown in Table 2.

Table 2. Analysis of variance of reliability index values

|

Variable |

Source of variation |

Degree of freedom |

F– value calculated |

P– value |

F–value critical |

SS |

|

UCS 7 |

COV |

9 |

29.13 |

3.96E-5 |

4.16 |

SS |

|

WRO |

COV |

9 |

29.59 |

3.62E-5 |

4.16 |

SS |

|

HM |

COV |

9 |

29.5 |

3.68E-5 |

4.16 |

SS |

|

C |

COV |

9 |

28.8 |

4.23E-5 |

4.16 |

SS |

|

QD |

COV |

9 |

28.79 |

4.23E-5 |

4.16 |

SS |

|

C3S |

COV |

9 |

28.72 |

4.3E-5 |

4.16 |

SS |

|

C2S |

COV |

9 |

28.69 |

4.32E-5 |

4.16 |

SS |

|

C3A |

COV |

9 |

28.79 |

4.23E-5 |

4.16 |

SS |

|

MDD |

COV |

9 |

31.44 |

2.54E-5 |

4.16 |

SS |

SS = statistically significant at 5% level

Using the F-distribution test at 95% level of significance the safety index shows a statistically significant outcome. Therefore care must be taken in ensuring that the parameters that produced successful safety index are carefully monitored because they have influence on the value of the unconfined compressive strength. Table 2 shows that from the parameters, the one that has more significant effects on the unconfined compressive strength test is maximum dry density then in descending order of their significant effect are water content relative to optimum, hydraulic modulus, cement, quarry dust, tri-calcium aluminate, tri-calcium silicate, di-calcium silicate.

Stochastically Model Assessment on the 7 days unconfined compressive strength

The safety index obtained for the 7 days unconfined compressive strength is tabulated in Table 3 [17]. Specified a safety index value of 1.0 as the lowest value for serviceability limit state design (model 1) of structural components.

Table 3. Stochastically Model Assessment of acceptable safety index

|

Variables Factors |

Beta Value |

Acceptable Range of COV (%) |

|

UCS 7 |

3.63 – 2.88 |

10 -100% |

|

WRO |

3.62 – 2.70 |

10-100% |

|

HM |

2.99 – 3.00 |

10-100% |

|

C |

3.62 – 3.62 |

10-100% |

|

QD |

3.63 – 3.61 |

10-100% |

|

C3S |

3.94 – 2.84 |

10-100% |

|

C2S |

3.92 – 3.50 |

10-100% |

|

C3A |

3.63 – 3.62 |

10-100% |

|

MDD |

2.79 – 0.91 |

10-60% |

Conclusions

Reliability estimates of unconfined compressive strength of compacted Quarry dust/Cement treated black cotton soil was under taken by incorporating a predictive model. This was developed from the data obtained from laboratory results for specimens compacted at British standard light (BSL) compaction energy. Results were incorporated into a FORTRAN-based first-order reliability program and safety index values obtained.

Generally, the safety indexes produced for the unconfined compressive strength was satisfactory because the beta values obtained are greater than 1.0 specified for serviceability limit state design.

Compositional factor and compound formations based on admixture combination ratio such as WRO, HM, QD, C, C3S, C2S and C3A also produced acceptable safety index value of 1.0 at COV ranges of 10 – 100% except the MDD that produces acceptable safety index value of 1.0 at COV range of 10 – 60 %. Observed trends for unconfined compressive strength indicate that the WRO, C3S, C2S, and MDD is greatly influenced by the COV and therefore must be strictly controlled in QD/C treated black cotton, while HM, QD, C and C3A are not affected by COV because they are responsible for the strength gain in the black cotton soil – quarry dust – cement mixture.

Stochastically, British Standard light (BSL) can be used to model the 7 days unconfined compressive strength of compacted quarry dust/cement treated black cotton soil as a sub-base material for road pavement at all COV range 10 – 100% because the safety index obtained are higher than the acceptable 1.0 value.

Apendix

PROGRAM FLOOR

C THIS PROGRAM EVALUATES THE RELIABILITY OF IRON ORE TAILING

C WITH CEMENT ON COMPRESSIVE STRENGH OF LATERITIC BRICKS

C BASED ON THE REGULATORY MINIMUM COMPRESSIVE STRENGTH

IMPLICIT DOUBLE PRECISION (A-H,O-Z)

EXTERNAL GFLOOR

DIMENSION X(4),EX(4),SX(4),VP(10,4),COV(4,4),ZES(3),

+ UU(4),EIVEC(4,4),IV(2,4),des(4)

CHARACTER*10 PRT

COMMON/CFLOOR/E

DATA EX/5.0D0,2.7D2,5.18D-1,1.75D1/,

+ SX/5.40D0,5.86D1,3.63D-1,1.292D1/,

+ N/4/,NC/4/,NE/4/,IRHO/0/

WRITE(*,*)'ENTER THE COEFF. OF VAR. FOR X(4) IN %....>'

READ(*,*)VAR

SX(1)=VAR*EX(1)/100.

do 707 k=1,8

NAUS=7

ICRT=0

OPEN(7,FILE='AKAN1.RES',STATUS='OLD',ERR=10)

GOTO 20

10 OPEN(7,FILE='AKAN1.RES',STATUS='NEW')

20 CALL YINIT (N,IV,VP,IRHO,COV,NC)

IV(1,1)=3

IV(1,2)=3

IV(1,3)=3

IV(1,4)=2

DO 100 I=1,N

X(I) = EX(I)

VP(8,I)=1.D0

100 CONTINUE

V1=1.D0

BETA=1.D0

WRITE (NAUS,5000)

5000 FORMAT (////,6X,70('*'),/,30X,'F O R M 5',/,6X,70('*'),/,

+'SAFETY CHECK ON TREATED FOUNDRY, 4 VARIABLES:')

CALL YKOPF (NAUS, N, IV, EX, SX, VP, IRHO)

WRITE (ICRT,*) ' START OF FORM5'

WRITE (ICRT,*) ' STOCHASTIC MODEL :'

CALL YKOPF (ICRT, N, IV, EX, SX, VP, IRHO)

PRT=' COV '

CALL YMAUS (NAUS,NC,N,COV,PRT)

CALL FORM5 (N, IV, EX, SX, VP, GFLOOR, IRHO, COV, NC,

+ EIVEC, NE, V1, NAUS, BETA, X, UU, ZES, IER)

C

C POTENTIAL LOSS IS HERE DETERMINED

PF = YPHINF(-BETA)

PL = (0.95*(1.0-EXP(-50.*PF)))*PF*100.

C WRITE(*,*)'POTENTIAL LOSS =',PL

C WRITE(NAUS,*)'POTENTIAL LOSS =',PF

PRT=' UU '

CALL YFAUS (NAUS,N,UU,PRT)

PRT=' ZES '

CALL YFAUS (NAUS,6,ZES,PRT)

do 777 i=1,n

des(i)=x(i)/ex(i)

777 continue

write(naus,888)(des(i),i=1,n),E

WRITE(NAUS,504)

write(NAUS,505)(uu(i)/beta,i=1,n)

504 FORMAT(/,3X,'ALPHA VECTOR:')

505 format(3x,/3X,6(2X,E10.2)/)

888 format(3x,//7f10.2/3x,6f10.2/3x,'aspect ratio for joist =',f8.2/

+ 10x,10('*')/)

C

WRITE(NAUS,*)'POTENTIAL LOSS =',PL

WRITE(NAUS,*)'POTENTIONAL FAILURE=',PF

707 continue

WRITE (ICRT,*) ' END OF FORM5 : IER =',IER

WRITE (ICRT,*) ' RESULTS SEE FILE AKAN1.RES'

STOP

END

SUBROUTINE GFLOOR (N, X, FX, IER)

IMPLICIT DOUBLE PRECISION (A-H,O-Z)

DIMENSION X(N)

COMMON /CFLOOR/E

C CHECK FOR ERRORS, CALCULATE FX

C IF (X(1).GT.0.AND.X(2).GT.0.AND.X(3).GT.0.AND.X(4).GT.0.AND.X(5).

C 2GT.0.AND.X(7).GT.0.AND.X(8).GT.0.AND.X(9).GT.0)THEN

IF (X(1).GT.0.)THEN

FX =-(X(1))+(26.700-0.0708*X(2)+9.280*X(3)+0.590*X(4))

IER = 0

ELSE

FX = 1.D+20

IER = 1

ENDIF

RETURN

END

References

1. Dey A., Kudmetha, K.K., Bearing Capacity of Single Pile in Sand: Reliability Analysis using Monte-Carlo Simulation, Proceedings of Indian Geotechnical Conference, December 22-24, 2013, Roorkee, India.

2. Eberemu O.A., Evaluation of compacted bagasse ash treated laterite soil as hydraulic barriers in waste containment systems. Unpublished Ph.D Dissertation submitted to the Department of Civil Engineering, Ahmadu Bello University, Zaria, 2008.

3. Osinubi, K.J., Eberemu, A.O., Yohanna, P., Etim, R.K., Reliability Estimate of the Compaction Characteristics of Iron Ore Tailings Treated Tropical Black Clay as Road Pavement Sub-Base Material. Downloaded from ascelibrary.org by Dogu Akdeniz Universitesi on 08/17/2016. Copyright ASCE. For personal use only; all rights reserved, p. 855 – 864.

4. Nwaiwu C.M.O., Afolayan J.O., Osinubi, K.J., Reliability Estimates of Field Hydraulic Conductivity of Compacted Lateritic Soils Continental, Journal of Engineering Science 4: 2009, p. 36– 47.

5. Eze-Uzomaka O.J., Agbo D., Suitability of quarry dust as improvement to cement stabilized-laterite for road bases, International journal of geotechnical engineering, 2010, p. 1053-1066.

6. Ibrahim A., Black cotton soil in road pavement design- construction and performance, In: S. A. Ola (ed.) Tropical Soils of Nigeria in Engineering Practice, A.A. Balkema. The Netherlands, Rotherdam, 1983, p. 260-278.

7. Akanbi D.O., Engineering properties of black cotton soil stabilized with quarry dust and cement. An unpublished B.Eng. Project of Civil Eng. Dept. ATBU Bauchi State, 2010.

8. TRRL, A guide to the structural design of Bitumen surfaced Roads in tropical and Sub – Tropical countries, Transport and Road Research Laboratory, Road Note 31, H. M. S. 0. London, 1977.

9. Kaymaz I., McMahon C., Xianyi M., Reliability based structural optimization using the response surface method and Monte Carlo simulation, 8th Int. Machine Design and Production Conf. Ankara, 1998.

10. Christian J.T., Baccher G.B., Discussion of factor of safety and reliability in Geotechnical Engineering, Journal of Geotechnical and Geoenvironmental Engineering, A.S.C.E., 2001, 127(8): 700-703.

11. Kotegoda M., Rosso R., Statistics, probability, and reliability for civil and environmental engineers, New York, McGraw-Hill, 1997.

12. Afolayan J.O., Abubakar I., Reliability analysis of reinforced concrete one-way slabs. The ultimate conditions, Nigerian Journal of Engineering, 2003, 11(2), 28 – 31.

13. Duncan M.J., Factors of safety and reliability in geotechnical engineering, Journal of Geotechnical Geoenenviromental Engineering, ASCE, 2000, 126(4), 307-316.

14. Gollwitzer S., Abdo T., Rackwitz, R., First Order Reliability Method (FORM Version 5) Manual, Munich, 1988, p. 1- 47.

15. Yisa G.L., Sani J.E., Reliability Estimate of Strength Characteristic of Iron Ore Tailing Stabilized Lateritic Soil for Road Pavement Sub-Base Materials, Electronic Journal of Engineering, 2014, 19:4177- 4192.

16. Sani J.E., Bello, A. O. and Nwadiogbu, C. P. (2014). “Reliability Estimate of Strength Characteristics of Black Cotton Soil Pavement Sub-Base stabilized with Bagasse Ash and Cement Kiln Dust”. International Institute for Science, Technology and Education (IISTE) Vol.6, No.11, pp 115 – 135.

17. NKB - Report No. 36. (1978) Recommendation for loading and safety regulations for structural design. Nordic Committee on Building Regulation.