Engineering, Environment

Development of resistance type moisture measuring device for grains

Sadiq Sius LAWAL1, Katsina Christopher BALA2*, Michael Bolaji ADEYEMI3

1,2,3Mechanical Engineering Department, Federal University of Technology, P.M.B. 65, Minna, Niger State, Nigeria

E-mail(s): 1sadiq.lawal@futminna.edu.ng; 2chrisbalamaik@yahoo.co.uk;

3mbadeyemi1@gmail.com

* Corresponding author, phone: +2348035980302

Received: November 19, 2016 / Accepted: June 14, 2017 / Published: June 30, 2017

Abstract

The paper presents a study aimed at developing an indigenous moisture measuring device from locally available materials for grains based on the principle of resistance change of the material with corresponding change in moisture during drying. The developed device has four copper electrode cups positions in which both gauging and dummy copper electrode cups were placed to form Wheatstone bridge circuits of full, half and quarter for four, two and one gauging copper electrode cups respectively, while the remaining positions were used as dummies. These circuits were used to measure the resistances and hence obtaining the moisture content of the grains used. Grains of paddy rice, guinea corn and millet were used to test the device and it was observed that for full bridge circuits of each of the grains, paddy rice have a negative coefficient of correlation of -0.95, -0.99 for guinea corn and -0.99 for millet. The results obtained from predictive empirical equations when compared with the direct oven method, showed that the device can be used to predict or measure moisture content once calibrated.

Keywords

Grains; Moisture; Resistance; Drying; Bridge circuits; Paddy rice; Guinea corn; Millet

Introduction

One of the most important factors in quality control of grains especially in controlling fungus infestations and for processing high quality grains is the moisture content of such grains [1]. For example, to produce high quality rice with very low breakages from parboiled paddy rice, the moisture content [2] of about 14% is considered a maximum limit. Beyond this percentage moisture content, paddy rice can result into quality deterioration and quantitative losses as a result of fungal, bacterial, insect and mite infestation [3,4]. Drying is one of the essential steps required in the post-harvest technology of grains such as rice, millet, maize and guinea corn. Drying processes can be achieved by sun or air drying [5], mechanical drying as well as oven drying [6]. During drying process, the moisture content of the grain is monitored using suitable moisture meter so as to achieve the correct percentage moisture content for processing and storage of such grains. Drying to appropriate percentage moisture content is one of the key indices of grain storage [7] and can result to retarding the development of mites and insects, elimination of bacteria and fungi growth, thereby enhancing maximum quality of the grain. Over drying may also cause deterioration of product in quality and quantity during production and storage stages of the grains.

Determination of grain moisture content can also be achieved through the use of electric moisture meters whose operations are based on the fundamental relationship between moisture content and a different electric property. These electrical methods include: conductance method (resistance-type), power-loss method, capacitance method, microwave method, and neutron method [7]. The conductance method [8,9] uses the relationship between moisture content and direct current conductance, the Power-loss method [10] uses the relationship between moisture content and the dielectric loss factor of the materials, while the capacitance method [11] utilizes the relationship between moisture content and the dielectric constant of the materials. The microwave method and neutron method have many advantages, such as high accuracy, fast speed, noncontact, non-invasive, and non-destructive measurement of the grain internal moisture. But the measurement devices are complex and expensive [12] as well as not able to measure readings below 7% moisture [13] as a result of very little change in the electrical conductivity.

In this research work, a resistance type moisture measuring device, based on the change of resistance with moisture loss of grain is developed and used to measure the percentage moisture content of grains such as paddy rice, guinea corn and millet. The effects of Wheatstone bridge circuits’ connection as full bridge, half bridge and quarter bridge on the measured resistances, and hence on the percentage moisture content of grains were investigated. Empirical equations relating the percentage moisture content to the measured resistance for each tested grain and the three bridge circuits employed were determined.

Material and method

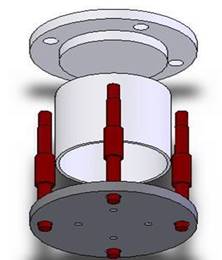

The experimental moisture measuring device used for measuring the moisture content of grains was similar to that constructed by Ogunleye [9]. The moisture measuring device was made of identical copper cup electrodes of equal dimensions and resistances, top and bottom steel plates, mild steel cylinder. A plunger made of solid Teflon was screwed to the top plate and the base plate. Four holes were drilled where the copper electrode cups were placed as shown in Figure 1(a). Connecting copper wires of equal lengths were used to connect the moisture device to a digital meter so as to eliminate the introduction of any additional resistance due to copper wires. The experimental setup is shown in Figure 1(b).

|

(a) |

(b) |

Figure 1. (a) Exploded view of the resistance type moisture measuring device (b) Experimental setup

The experimental procedure included:

- Placing of samples of the paddy rice of known masses on twenty identical containers of known masses.

- Placing of samples of the paddy rice in these containers inside a hot air oven set to a temperature of 1300C to dry for ten minutes.

- Measurement of the masses of the grain samples using a digital balance of maximum capacity 310 gm and sensitivity of 0.001 gm to determine the loss of moisture in the grain.

- Determining of percentage moisture content of the paddy rice as the ratio of the loss of moisture to the dry mass of the grain sample on dry basis as prescribed by [14].

- Samples of the paddy rice of known percentage moisture content were placed inside a mild steel cylinder positioned on the bottom plate cover with the copper electrode cups arranged as full, half and quarter Wheatstone bridge connections as shown in Figure 2.

|

(a) full bridge |

(b) half bridge |

(c) quarter bridge |

Figure 2. Wheatstone bridge arrangements of copper cup electrodes

- The top of the cylindrical container was covered with a top cover plate to which a Teflon plunger was attached and bolted to the bottom plate cover with bolt and nut arrangement to ensure constant pressure application on the paddy rice during resistance measurements.

- A high impedance electronic ohmmeter was used to measure the resistances of the paddy rice corresponding to the percentages moisture content of the grain obtained by the oven-drying method. The measured resistances for full bridge, half bridge and quarter bridge. Wheatstone bridge circuit was recorded for oven drying of the paddy rice at an interval of ten (10) minutes.

- The above procedures were repeated for other samples of paddy rice and for millet and guinea corn grains samples at varying oven drying time, until dry mass of each grain sample was achieved (i.e. no mass change).

Predictive empirical (regression) equations [15] were derived using a simple linear regression equation relating the percentage moisture content (%MC) to the resistance (R) in the form of equation (1).

![]() (1)

(1)

Where: a - coefficient of regression of the percentage moisture content; b - constant of regression. Values of a, b are given by [16] as in equations (2) and (3).

(2)

(2)

(3)

(3)

Where: N - number of observations.

The coefficient of correlation (or the correlation coefficient) is a measure of the strength of the linear relationship between two variables and its values lies between +1 and -1. Therefore, the coefficients of correlation [17] of all the predictive empirical equations were obtained from equation (4).

(4)

(4)

To calibrate the device to generate or derive the empirical equations for predicting the percentage moisture content and the corresponding coefficients of correlation, statistical calculations with MATLAB CODES [18] were employed using the experimental data inputted into equations (1), (2), (3) and (4) appropriately. The resulting respective predictive empirical equations are as follows Eq. (5-13):

For paddy rice

Full: %Mc = 40.85 - 16.05R (5)

Half: %Mc = 27.58 - 3.75R (6)

Quarter: %Mc = 23.42 - 2.06R (7)

For Guinea corn

Full: %Mc = 44.44 - 9.90R (8)

Half: %Mc = 42.97 - 4.42R (9)

Quarter: %Mc = 29.3 - 1.80R (10)

For Millet:

Full: %Mc = 60.22 - 10.45R (11)

Half: %Mc = 44.14 - 4.84R (12)

Quarter: %Mc = 44.24 - 3.65R (13)

These equations (5) to (13) were used to predict the percentage moisture content at corresponding resistances and the results compared with the direct oven method.

Results and Discussion

Table 1 presents the summary of all the coefficients of correlations for the grains and the various Wheatstone bridge arrangements.

Table 1. Summary of coefficients of correlation (γ)

|

Grains |

Coefficients of correlation (γ) |

||

|

Full bridge |

Half bridge |

Quarter bridge |

|

|

Paddy rice |

-0.95 |

-0.88 |

-0.58 |

|

Guinea corn |

-0.99 |

-0.94 |

-0.42 |

|

Millet |

-0.99 |

-0.53 |

-0.47 |

The results obtained for the moisture content of the various grains at various drying time intervals is presented in Figure 3.

Figure 3. Moisture content

Figure 3 shows that for all the grains samples tested the percentage moisture content decreases with drying time due to loss of moisture.

Figure 4 is the resistances (full, half and quarter bridges) versus moisture content for paddy rice.

Figure 4. Resistance of paddy rice versus moisture

Figure 5 shows the resistances (full, half and quarter bridges) versus moisture content for guinea corn while Figure 6 is the resistances (full, half and quarter bridges) against the moisture content for millet.

Figure 5. Resistance of guinea corn versus moisture

Figure 6. Resistance of millet versus moisture

The resistances of the grains as presented in Figures 4, 5 and 6, are found to increase as the moisture content decreases. Similarly, the measured resistances of the full bridge arrangement are found also to be lower than the half and quarter bridge connections for all the grains. The values of the coefficients of correlation obtained in Table 1 imply that the full bridge is gave the near perfect negative correlation of [17]. From Table 1 shows that the coefficients of correlation values lies between +1 and -1and this indicates the measure of the strength of the linearity between the percentage moisture content and the resistances [15,17]. This means also that the moisture content of the grains has a corresponding relationship with the resistances. This further substantiates the fact that as the moisture content decrease (loss of water), the resistance increases as seen from Figures 4, 5 and 6. Table 1 also show clearly high sensitivity with high negative coefficients of correlation when the device was operated with the full Wheatstone bridge arrangements. Next to the full Wheatstone bridge arrangements in term of sensitivity and coefficients of correlation is the half Wheatstone bridge and lastly the quarter Wheatstone bridge arrangements.

Figure 7 is the predicted moisture content of paddy rice for full, half and quarter bridges from the device after calibration against the moisture content obtained by direct oven method.

Figure 7. Predicted moisture content of paddy rice

Figure 8 shows the predicted moisture content of guinea corn for full, half and quarter bridges from the device after calibration against the moisture content obtained by direct oven method.

Figure 8. Predicted moisture content of guinea corn

Figure 9 presents the predicted moisture content of millet for full, half and quarter bridges from the device after calibration against the moisture content obtained by direct oven method. The results of direct measurement for the calibration of the device are presented in Appendix A, as Tables 2, 3 and 4 for paddy rice, guinea corn and millet respectively.

Figure 9. Predicted moisture content of millet

The comparison between the predicted values and the percentage moisture contents of the various grains, using the different bridge arrangements versus the direct oven method for the grains are shown in Figure 7 for paddy rice, Figure 8 for guinea corn and Figure 9 for millet. The Figures showed that the full bridge arrangements are the most correlated (accurate) followed by the half bridge and lastly by the quarter bridge copper electrode arrangements. This trend was also the case in Table 1 for all the grains. This further asserts the sensitivity and high negative coefficients of correlation of the full bridge configuration of the application of the device. Therefore, accurate measurement of moisture content using this device is better achieved with the full bridge configuration for all the grains.

Conclusions

A resistance type moisture measuring device for grains was developed and investigations conducted on paddy rice, guinea corn and millet to obtain the resistances of the grains using a Wheatstone bridge arrangement. The resistances obtained for all the grains are found to increase as the percentage moisture content decreases.

The empirical equations relating percentages of moisture content to the measured resistances shows that the full bridge connection gives the best correlation as indicated by the high correlation coefficients obtained.

The results obtained have shown that with the various Wheatstone bridge circuits it can be concluded that the locally developed device can be used to determine the moisture content of any grain.

Appendix

Table 2. Measurement for calibration of the device for paddy rice samples

|

S/No |

Time (Minutes) |

Mass, Ww (g) |

% Moisture Content (%MC) |

Resistances R (MΩ) |

||

|

Full Bridge |

Half Bridge |

Quarter Bridge |

||||

|

1 |

0.00 |

75.947 |

30.09255 |

0.8 |

0.9 |

0.9 |

|

2 |

10.00 |

75.324 |

28.67934 |

0.9 |

1.0 |

1.1 |

|

3 |

20.00 |

74.512 |

26.8374 |

1.0 |

1.1 |

1.2 |

|

4 |

30.00 |

73.492 |

24.52364 |

1.1 |

1.2 |

1.4 |

|

5 |

40.00 |

72.078 |

21.31612 |

1.2 |

1.3 |

1.7 |

|

6 |

50.00 |

70.941 |

18.73696 |

1.3 |

1.5 |

1.9 |

|

7 |

60.00 |

69.615 |

15.72906 |

1.4 |

1.8 |

2.1 |

|

8 |

70.00 |

69.027 |

14.39525 |

1.5 |

1.9 |

2.2 |

|

9 |

80.00 |

68.044 |

12.16541 |

1.6 |

3.4 |

5.5 |

|

10 |

90.00 |

66.931 |

9.640686 |

1.7 |

4.5 |

6.4 |

|

11 |

100.00 |

65.812 |

7.10235 |

2.2 |

5.5 |

7.3 |

|

12 |

120.00 |

65.550 |

6.50803 |

2.4 |

6.6 |

- |

|

13 |

130.00 |

64.717 |

4.693 |

- |

- |

- |

|

14 |

140.00 |

63.687 |

2.319 |

- |

- |

- |

|

15 |

150.00 |

62.701 |

0.05 |

- |

- |

- |

|

16 |

160.00 |

62.681 |

0 |

- |

- |

- |

Table 3. Measurements for the calibration of the device for guinea corn samples

|

S/No |

Time (Minutes) |

Mass, Ww (g) |

% Moisture Content (%MC) |

Resistances R (MΩ) |

||

|

Full Bridge |

Half Bridge |

Quarter Bridge |

||||

|

1 |

0.00 |

75.947 |

35.85862 |

0.8 |

0.9 |

1.0 |

|

2 |

10.00 |

75.219 |

34.13403 |

1.1 |

1.4 |

2.2 |

|

3 |

20.00 |

74.645 |

32.77426 |

1.3 |

2.6 |

2.9 |

|

4 |

30.00 |

72.795 |

28.39173 |

1.5 |

4.0 |

3.2 |

|

5 |

40.00 |

71.948 |

26.38524 |

1.8 |

4.6 |

4.2 |

|

6 |

50.00 |

70.471 |

22.88631 |

2.3 |

5.8 |

4.5 |

|

7 |

60.00 |

69.384 |

20.31128 |

2.6 |

5.9 |

5.7 |

|

8 |

70.00 |

66.840 |

14.2847 |

2.8 |

6.2 |

6.4 |

|

9 |

80.00 |

66.288 |

12.97704 |

3.1 |

6.5 |

6.7 |

|

10 |

90.00 |

64.527 |

8.805344 |

3.6 |

6.9 |

7.7 |

|

11 |

100.00 |

63.155 |

5.555161 |

4.0 |

7.3 |

- |

|

12 |

120.00 |

62.409 |

3.788 |

- |

- |

- |

|

13 |

130.00 |

61.826 |

2.407 |

- |

- |

- |

|

14 |

140.00 |

60.846 |

0.09 |

- |

- |

- |

|

15 |

150.00 |

60.828 |

0.04 |

- |

- |

- |

|

16 |

160.00 |

60.810 |

0 |

- |

- |

- |

Table 4. Measurement for calibration of the device for millet samples

|

S/No |

Time (Minutes) |

Mass Ww (g) |

% Moisture Content (%MC) |

Resistances R (MΩ) |

||

|

Full Bridge |

Half Bridge |

Quarter Bridge |

||||

|

1 |

0.00 |

75.947 |

35.85862 |

0.8 |

0.9 |

1.0 |

|

2 |

10.00 |

75.219 |

34.13403 |

1.1 |

1.4 |

2.2 |

|

3 |

20.00 |

74.645 |

32.77426 |

1.3 |

2.6 |

2.9 |

|

4 |

30.00 |

72.795 |

28.39173 |

1.5 |

4.0 |

3.2 |

|

5 |

40.00 |

71.948 |

26.38524 |

1.8 |

4.6 |

4.2 |

|

6 |

50.00 |

70.471 |

22.88631 |

2.3 |

5.8 |

4.5 |

|

7 |

60.00 |

69.384 |

20.31128 |

2.6 |

5.9 |

5.7 |

|

8 |

70.00 |

66.840 |

14.2847 |

2.8 |

6.2 |

6.4 |

|

9 |

80.00 |

66.288 |

12.97704 |

3.1 |

6.5 |

6.7 |

|

10 |

90.00 |

64.527 |

8.805344 |

3.6 |

6.9 |

7.7 |

|

11 |

100.00 |

63.155 |

5.555161 |

4.0 |

7.3 |

- |

|

12 |

120.00 |

62.409 |

3.788 |

- |

- |

- |

|

13 |

130.00 |

61.826 |

2.407 |

- |

- |

- |

|

14 |

140.00 |

60.846 |

0.09 |

- |

- |

- |

|

15 |

150.00 |

60.828 |

0.04 |

- |

- |

- |

|

16 |

160.00 |

60.810 |

0 |

- |

- |

- |

References

1. Wang W.P., Design and development of resistive grain moisture meter, Applied Mechanics and Materials, 2015, 716, p. 961-964.

2. Baird J.H., Grading and maintaining grain quality in storage, Proceeding of Australian Centre for International Agricultural Research, 1987, 19, p. 35-41.

3. Khan A.R., Mannan A., Stored-products entomology in the tropics, Agricultural Zoology Reviews, 1991, 4, p. 67-95.

4. Suryalkanta P. (Online), Moisture content determination using rapid moisture meter, Available at: civilblog.org IS:2720-part 2(accessed 13/5/2013)

5. Banga J.R., Singh R.P., Optimization of air drying of foods, Journal of Food Engineering, 1994, 23, p. 189-211.

6. ElSayed N.I., Mekawy M.M., Megahed F.M., Uncertainty of moisture measurements methods for grains, Australian Journal of Basic and Applied Science, 2011, 5(7), p. 582-587.

7. Zhe L., Zhan W., Zhongjie Z., Wenfu W., Hexin L., Research on online moisture detector in grain drying process based on V/F conversion, Hindawi, Mathematical Problems in Engineering, 2015.

8. Wexler A., Humidity and moisture measurements and control in science and industry, Reinhold Publisher, New York, 1965.

9. Ogunleye I.O., Adeyemo S.B., Adeyemi, M. B., Development of moisture measuring device for cassava particulate during drying, Advance Materials Research, Trans Tech Publications, Switzerland, 2007, 18, p. 171-176.

10. Nelson S.O., Use of electrical properties for grain-moisture measurement, Journal of Microwave Power, 1977, 12(1), p. 67-72.

11. Kandala K., Nelson S.O., Lawrence K.C., Non-destructive electrical measurement of moisture content in single kernels of com, Journal of Agricultural and Engineering Research, 1989, 44, p. 125-132.

12. Wang W.C., Dai Y.Z., A grain moisture detecting system based on capacitance sensor, International Journal of Digital Content Technology and Applications, 2011, 5(3), p. 203-209.

13. Makoto K., Mycotoxin prevention and control in food grains: Corn Sheller and Moisture meter. ISO – 8859 -1, 2012.

14. American Society for Testing and Materials (ASTM), Methods of Measuring Moisture Content of Wood, ASTM Standard D 2016, Philadelphia, PA.

15. Dalela S., Mansoor A.L., Industrial engineering and production management, K Jan Standard Publisher Distribution, 2006.

16. Murray R.S., Larry J.S., Theory and problems of statistics, McGraw-Hill, Schaum’s outline series, London, 2007.

17. Egbe E., Odili G.A., Ugbebor O.O., Further mathematics, Africana-Fep Publishers Plc, Nigeria, 2010.

18. Lawal S.S., Development of resistant type moisture content measuring device for grains, M. Eng. Thesis, Department of Mechanical Engineering, Federal University of Technology, Minna, 2014.