Engineering, Environment

Desiccation effect of compacted tropical black clay treated with concrete waste

George MOSES 1, Roland Kufre ETIM 2*, John Egbonye SANI 3, Micheal NWUDE 4

1,3Department of Civil Engineering, Nigerian Defence Academy, Kaduna, Nigeria

2Department of Civil Engineering, Akwa Ibom State University, Ikot Akpaden, Nigeria

4National Water Resource Institute Kaduna, Nigeria

E-mails: 1mgeorge@nda.edu.ng, 2rolandkufre24@gmail.com,

3sejohn2000@yahoo.com, 4nwudemike@yahoo.com

*Corresponding author: +2347057639785

Received: July 05, 2018 / Accepted: August 16, 2018 / Published: December 30, 2018

Abstract

A tropical black clay soil was treated with up to 50% concrete waste (CW) by weight of dry soil and compacted at molding water contents (MWC) -2, 0, 2 and 4% of optimum moisture content (OMC) using British Standard light (BSL) and British Standard heavy (BSH). Samples were extruded from the compaction molds and allowed to air dry at 25 ± 20C in the laboratory in order to assess the effect of desiccation-induced shrinkage on the material for use as a hydraulic barrier in waste containment application. The maximum dry density (MDD) increased with increased CW content. Also, the optimum moisture content (OMC) increased to its peak value of 22.9% at 20% CW treatment for the BSL while peak OMC value of 20.6% at 30% CW treatment was established for BSH compactive effort. The loss in mass was obvious within the first five days of exposure to air and thereafter became relatively constant by the tenth - fifteenth day until samples were entirely dried at thirtieth day. The volumetric shrinkage strain (VSS) were also large within the first 5 days of drying. The VSS increased with higher molding water content and water content relative to the optimum. Regardless of the compactive effort effect, peak VSS were established at 20% and 10% CW treatment for -2 to +2 and +4 molding water content, respectively. Beyond 10 – 20 % CW treatment, VSS decreased steadily. Although, the two-way analysis of variance shows that both CW and water content relative to optimum (WRO) are statistically significance, none of the treatment gave the regulatory value of ≤ 4% required for waste containment application.

Keywords

Compaction; Black cotton soil; Concrete waste; Volumetric shrinkage strain (VSS); Waste containment; Molding water content; Regression, Correlation

Introduction

Proper waste management practice has not been effectively adopted in most developing countries and has been recognized as one of the greatest challenges facing many communities in Nigeria. Construction activities have been known to generate large and diverse quantities of waste. Also, construction and demolition waste management has become one of the major environmental problems in many municipalities [1, 2]. According to Lim and Chu [3] limited waste landfill space, increasing cost of waste disposal in combustion facilities and landfills, depletion of the natural resources, and the need for sustainable development have all amplified the need to reuse the materials that were once regarded as wastes as substitutes for natural resources.

The nature of landfill covers makes them exposed to the atmosphere and during relatively dry conditions or in arid sites the clay layer are prone to damage from shrinkage or desiccation. Large cracks can also occur in wet compacted clays that are allowed to dry. Compacted clay liners inland fill covers undergo seasonal changes in water content even at great depth, due to seasonal variation in precipitations and evapotranspiration [4, 5]. Field studies have shown that desiccation can induce large cracks [5, 6, 7, 8]. This can lead to an increase in hydraulic conductivity of the barrier material thus making it exceed the regulatory minimum value and allowing the movement of leachate through. The maximum volumetric shrinkage strain of 4 % is recommended for a material to be suitable for the construction of a liner [9]

The waste discarded by the construction companies, people and organizations have the potential to be reused for their original purposes or for new ones. Additionally, reusing products conserves natural resources and saves valuable landfill space. Use of environment-friendly materials in any industry is of paramount importance. Also, limited waste landfill space, increasing cost of waste disposal in combustion facilities and landfills, depletion of the natural resources, and the need for sustainable development have all amplified the need to reuse the materials that were once regarded as wastes as substitutes for natural resources [3]. Construction and demolition wastes like bricks, concrete, tiles etc. may be used for mechanical stabilization of very poor soils, by adding extra cementitious materials or commercial stabilizers [10]. Alternatively, it may be used partly as soil after doing testing on leachability, durability in addition to unconfined compressive strength. After satisfactory trial results, this type of mixed material may be used for stabilization of poor soil alone or by mixing with some good soils and/or with suitable additives.

From the preceding, waste especially from construction sites such as bricks, tiles and concrete if not properly contained or managed may constitute nuisance to the environment and of course to human health in the long run. Also, few or little studies exist in its use as admixture to reduce the shrinkage behaviour of tropical black clay soil. However, the behaviour of wet compacted clays where large cracks have been reported to emerge when allowed to dry [11] becomes necessary to investigate the volumetric shrinkage behaviour of compacted tropical black clay- CW mixtures. Besides low permeability characteristics for which high clay content soil are known for [12, 13, 14], low volumetric shrinkage strain limit is also one of the criteria used in characterizing clay material suitable for use as liner and or cover in hydraulic barrier system. Consequently, the need to study the effect of construction waste particularly from demolished concrete waste on its desiccation effect on black cotton soil becomes not only necessary but relevant in considering its usage in liners and covers in waste containment systems.

Although, the effect of CW on hydraulic conductivity of black cotton soil was not considered in this study, it is hoped that a better understanding of its effect on the volumetric shrinkage strain will add to the body of existing knowledge that abound on desiccation effect of tropical black clay and other clays soils for use in liners and cover in hydraulic barrier facilities.

This study, therefore evaluate the influence of construction waste particularly concrete waste on the shrinkage behaviour of tropical black clay.

Materials and method

Soil: The soil used in this study is a black cotton soil collected from Numan Local Government Area, Adamawa State in North East part of Nigeria, (latitude 09o 36’ N and longitude 11o 47’ E), by using the method of disturbed sampling at 1m depth from the natural earth surface to avoid organic matter influence. Previous X-ray diffraction studies of the soil in the burrow area show montmorillonite as the dominant clay. It is dark grey in color and classified as A-7-6(26) according to AASHTO soil classification system [15] and CH according to the Unified Soil Classification System [16].

Concrete waste (CW): The concrete waste used in this study was collected from a construction waste material of demolished structures along college road Angwan Dosa, Igabi Local Government Area (Latitude 10 47’N and Longitude 7 46’E), Kaduna state, Nigeria. The CW was carefully sieved through 0.075 mm aperture (BS No. 200) sieve to eliminate undesirable materials. The sieved specimen was preserved in an airtight container to avoid pre-hydration and kept in the laboratory for usage. The CW was mixed with the soil in varied increment of 2% from 0% to 8% by weight of dry soil to form five different soil – CW blends.

Index Properties: Laboratory tests were performed to determine the index properties of the natural soil and soil mixtures in accordance with British Standards [17, 18].

Compaction: British Standard Light (BSL) and British Standard Heavy (BSH) energies were used in tests involving the moisture density relationship and volumetric shrinkage. The air-dried soil samples passed through 4.76 mm (BS No. 4) sieve size and mixed with 0, 2, 4, 6 and 8 % CW by weight of dry soil. British Standard Light (BSL) and British Standard Heavy (BSH) compactive efforts were conducted in accordance with British Standard [17]. The BSH and BSL compactions are the British Standard (BS) equivalents of the Modified and Standard Proctor compactions (ASTM D1557 and ASTM D698), respectively.

Volumetric shrinkage: The volumetric shrinkage upon drying was measured by extruding cylindrical specimens, compacted using two compactive effort (BSL and BSH) above on well mixed concrete waste (CW) mixtures (natural soil, 10, 20, 30, 40 and 50 % concrete waste contents) at four different molding water contents i.e., 2 % dry of optimum (-2 %), optimum moisture content (0 %), 2 % wet of optimum (+2 %) and 4 % wet of optimum (+4 %), from the compaction molds. The extruded cylindrical specimens were air dried on a laboratory table at a uniform temperature of 25 ± 2ºC for a period of 30 days. Three measurements of diameter and height, respectively, for each specimen were taken every 5 days with the aid of a digital Vernier caliper accurate to 0.01 mm. The mean dimensions (diameters and heights) were recorded and Eq. [1] was used to compute the volumetric shrinkage strain.

![]() (1)

(1)

Where: VSS - is volumetric shrinkage strain, Vo - is original volume of moist compacted cylindrical specimen and Vf - is the final volume of dry compacted cylindrical specimen.

Results and discussion

Physicochemical properties of materials

The oxide composition of black Cotton Soil (BCS) and concrete waste (CW) as determined from the Atomic Absorption Spectrophotometer (AAS) of the Nigerian Geological Survey Agency Kaduna, Nigeria, are presented in Table 1. The oxides composition shows that the BCS contain higher percentage of SiO2 (51.41%) and very low CaO (3.38%) while CW on the other contain higher percentage of CaO (55.26%) which is responsible for the increase in strength and thereby stabilizing the problematic soil.

Table 1. Oxide composition of black cotton soil (BCS) and construction waste (CW)

|

Oxide composition |

BCS (%) |

CW (%) |

|

SiO2 |

51.41 |

17.26 |

|

Al2O3 |

20.29 |

3.30 |

|

MgO |

1.22 |

1.99 |

|

K2O |

0.55 |

1.89 |

|

CaO |

3.38 |

55.26 |

|

Ti2O |

2.73 |

1.45 |

|

P2O5 |

0.05 |

0.08 |

|

SO3 |

0.06 |

0.03 |

|

V2O5 |

0.15 |

0.03 |

|

Fe2O3 |

13.20 |

8.34 |

|

MnO |

1.08 |

0.02 |

|

NiO |

0.07 |

0.04 |

|

CrO3 |

0.02 |

0.01 |

|

Na2O |

0.06 |

0.04 |

|

ZnO |

0.05 |

ND |

|

CeO2 |

ND |

0.03 |

|

ZrO2 |

0.01 |

0.09 |

|

Eu2O3 |

0.02 |

0.06 |

|

CuO |

0.02 |

0.04 |

|

LOSS ON IGNITION (LOI) |

4.87 |

10.25 |

Summary of the results of the physical properties of the natural soil used in this study presented in Table 2. The soil is classified under the A-7-6 (26) subgroup of the AASHTO classification system [15] or CH in the unified Soil Classification System (USCS) [16]. The liquid limit and plasticity index values of 70.63 and 31 %, respectively, indicate suggest signify that the soil is highly plastic.

Table 2. Results of tests on natural black cotton soil

|

Property |

Quantity |

|

Percentage passing BS No 200 sieve (%) |

75 |

|

Natural moisture content (%) |

14.5 |

|

Liquid limit (%) |

70.63 |

|

Plastic limit (%) |

32 |

|

Plasticity index (%) |

31 |

|

Linear shrinkage (%) |

21 |

|

Specific gravity |

2.34 |

|

Free swell |

90 |

|

AASHTO classification |

A-7-6 (26) |

|

USCS |

CH |

|

NBRRI classification |

High swell potential |

|

Maximum dry density (mg/m3) British Standard light West African Standard |

1.45 1.67 |

|

Optimum moisture content (%) British Standard light (standard proctor) British Standard heavy (modified proctor) |

17 15 |

|

Colour |

Dark grey |

|

Dominant clay mineral |

montmorillonite |

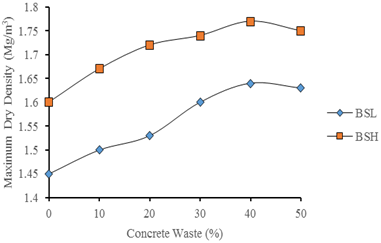

Compaction characteristics

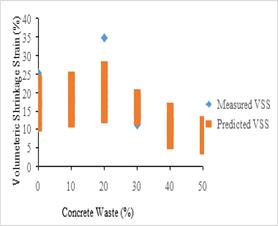

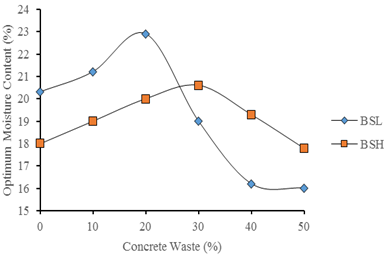

The variation of maximum dry density (MDD) and optimum moisture content (OMC) with concrete waste (CW) is shown in Figure 1 and 2.

Figure 1. Effect of concrete waste on maximum dry density of black cotton soil – concrete waste mixture

Figure 2. Effect of concrete waste on optimum moisture content of black cotton soil – concrete waste mixture

The MDD values ranged from 1.45 to 1.64 Mg/m3 and from 1.60 to 1.77 Mg/m3 for BSL and BSH compactive efforts, respectively. Similarly, the optimum moisture content (OMC) ranged from 16 to 22.9 % and from 17.8 to 20.6 % for BSL and BSH or modified Proctor efforts, respectively. Generally, the maximum dry density (MDD) increased with increasing CW content. The increase in MDD is due to the comparatively low specific gravity value of 2.34 of the soil compared to that of the CW which is 2.38. This is in agreement with the report of Osinubi et al [19] and Etim et al [20] who used iron ore tailing as admixture in cement and lime stabilization of black cotton soil.

The optimum moisture content (OMC) initially increased and later decreased with higher CW content. OMC increased and peaked at 20 and 30 % CW content for BSL and BSH effort, respectively. The OMC initially increased with higher CW treatment due to the increase in fines content from the CW with larger surface areas that required more water for hydration. The OMC subsequently decreased due to self - desiccation in which all the water was used, resulting in low hydration.

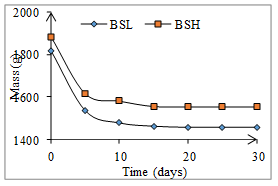

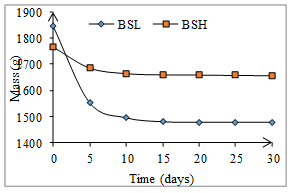

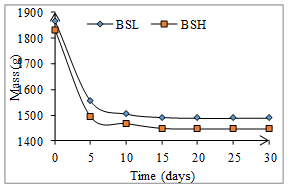

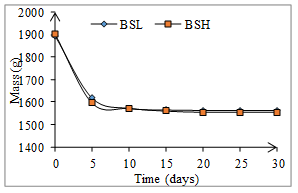

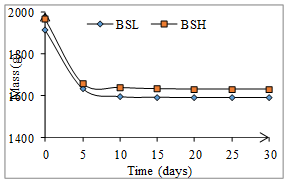

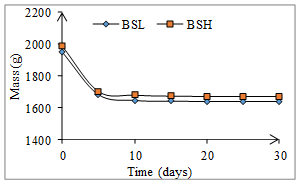

Changes during drying

The changes in mass that occurred during drying of the compacted cylindrical specimens prepared at various compactive efforts for up to 50 % CW treatment are shown in Figure 3-8. Generally, in all instances the loss in mass was obvious within the first five days of exposure to air as represented from the slope of the graphs and thereafter became relatively constant by the tenth - fifteenth day until samples were entirely dried. [21, 22, 23]. The changes in mass all through the drying period remained unaffected by the CW treatment and compactive effort used although specimens having higher compactive effort plotted above those having lower effort from the plots of changes in mass during drying which is due to the higher dry density generated by higher compactive effort [21, 22].

|

Figure 3. Plot of mass with time of volumetric shrinkage at the OMC for the natural soil |

Figure 4. Plot of mass with time of volumetric shrinkage at the OMC for 10% CW content |

|

Figure 5. Plot of mass with time of volumetric shrinkage at the OMC for 20% CW content |

Figure 6. Plot of mass with time of volumetric shrinkage at the OMC for 30% CW content |

|

|

|

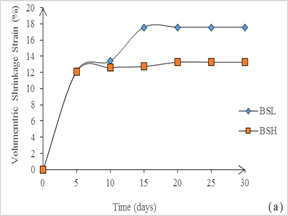

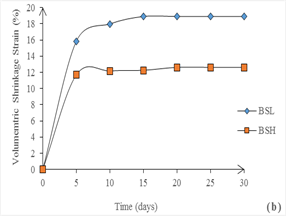

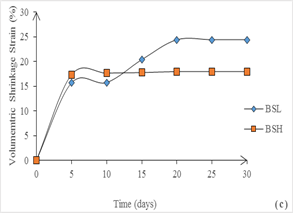

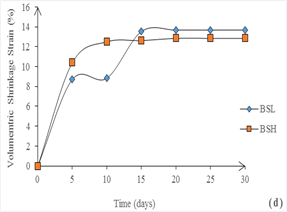

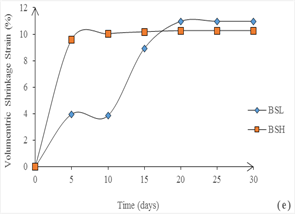

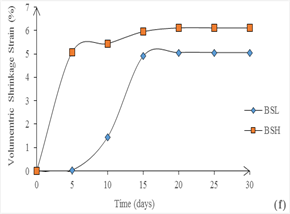

The results of volumetric shrinkage strain (VSS) with time for samples prepared at the OMC for the various compactive efforts with CW treatment up to 50 % is shown in Figure 9 (a-f). The rates of change in volumetric shrinkage strain were in general sharp within the first five days of exposure to air. Beyond this period, the VSS decreased gradually and became comparatively constant by the tenth-fifteenth day when the samples were fully dried for all the efforts used. These changes were influenced by the compactive efforts used which of course has direct relationship with molding water content i.e. volumetric shrinkage values where higher at lower compactive efforts which is due to the higher molding water content contained at lower compactive effort since volumetric shrinkage strain is proportional to the molding water content [21, 23].

|

|

|

|

|

|

|

|

|

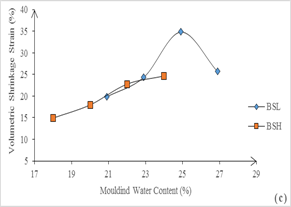

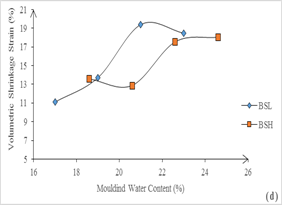

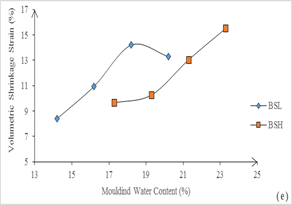

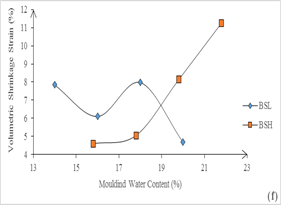

Figure 9. Variation of volumetric shrinkage strain with time at the OMC for (a) the natural soil (b) 10% CW (c) 20% CW (d) 30% CW (e) 40 % CW (f) 50% CW

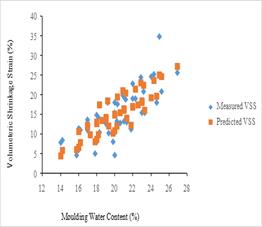

Effect of molding water content

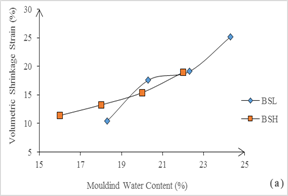

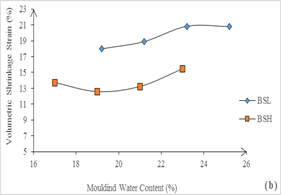

The variation of volumetric shrinkage strain with molding water content is shown in Figure 10 (a–f). Generally, VSS increased with higher molding water content. Specimens compacted at higher molding water content shrunk more during drying [4, 21]. This was so because drying shrinkage in fine-grained soils depends on particle movement as a result of pore water tension developed by capillary menisci [24]. If sizes, allowing greater capillary stresses and easier relative movement of particles and particle groups. Samples compacted at higher molding water contents have more water in their voids that enhance higher shrinkage on drying since volumetric shrinkage is proportional to the volume of water leaving the pore spaces during the drying process of saturated soils [25]. For the natural soil specimens compacted with the BSH effort in the molding water content range from -2 to +4% of the OMC recorded VSS values not less than 10.42%. Generally, lower VSS value were obtained at higher percentage (30 -50 %) of CW (see Figure 10e-f), but none of the percentage met the minimum 4%. At 50% CW treatment (see Figure 10f) the value of VSS recorded are very close to the 4% at molding water content of 15.8% for BSH compaction and 18% molding water content for BSL compaction.

|

|

|

|

|

|

|

|

|

Figure 10. Variation of volumetric shrinkage strain with molding water content for (a) the natural soil (b) 10% CW (c) 20% CW (d) 30% CW (e) 40 % CW (f) 50% CW

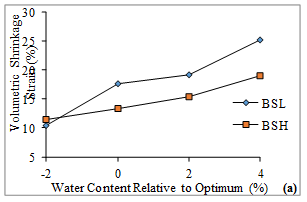

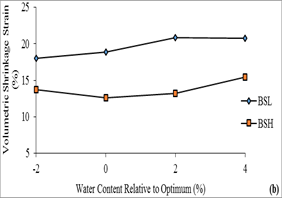

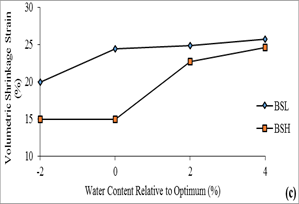

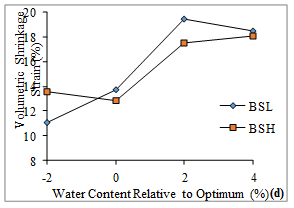

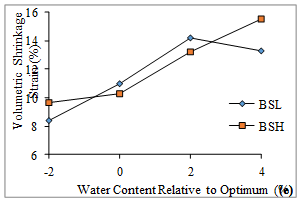

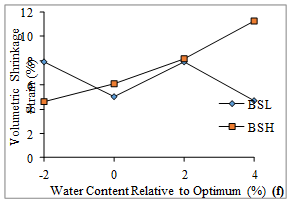

Effect of water content relative to optimum

The variation of volumetric shrinkage strain with water content relative to optimum is shown in (Figure 11a – f). Generally, volumetric shrinkage strain increased with higher molding water content relative to optimum. For the natural soil compacted at molding water contents in the range from -2 to +4% of the OMC. The maximum permissible VSS values of 4% were not obtained for all molding water content relative to optimum and for both compaction efforts. At 50% CW treatment VSS values recorded was very close to the maximum permissible VSS values of 4% at -2% and 0% OMC. Generally, specimens compacted at higher molding water content shrank more during drying and this is consistent with those reported by previous researchers [4, 21].

|

|

|

|

|

|

|

|

|

Figure 11. Variation of volumetric shrinkage strain with water content relative to optimum for (a) the natural soil; (b) 10% CW; (c) 20% CW; (d) 30% CW; (e) 40 % CW; (f) 50% CW

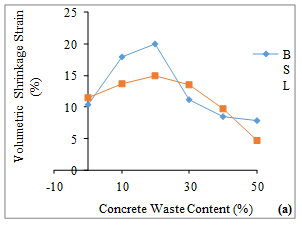

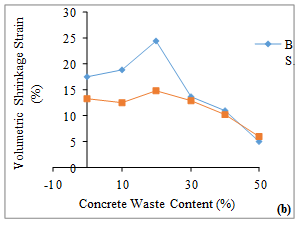

Effect of concrete waste (CW) content

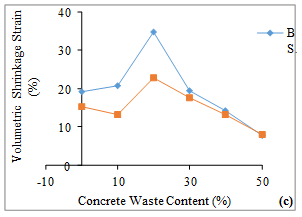

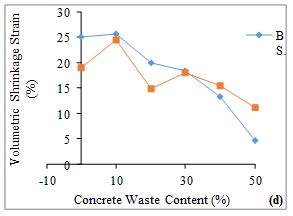

The variation of volumetric shrinkage strain with construction waste content at -2, 0, +2 and +4% OMC are shown in Figure 12 (a – d). Generally, VSS decreased with higher construction waste treatment for all compaction efforts used. This was due to the increase in OMC with higher construction waste as a result of the presence of more fines with larger surface area in the soil that required more water for reaction that increased shrinkage during drying.

|

|

|

|

|

|

Figure 12. Variation of volumetric shrinkage strain with construction waste for (a) -2 % OMC; (b) 0% OMC; (c) +2% OMC; (d) +4% OMC

Analysis of variance

Analysis of variance (two way) was done to check the effect of CW and molding water content or water content relative to optimum analysis of variance. The results (see Table 3) show that the variation of molding water content and CW had significant influence on the VSS for the different compactive efforts considered in this study.

Table 3. Results of two-way ANOVA for volumetric shrinkage strain in view of different compactive efforts

|

Compactive effort |

Source of Variation |

Degree of freedom |

F-value (calculated) |

P-value |

F-value (critical) |

Remark |

|

BSL |

CW |

5 |

18.751 |

5.65E-06 |

2.901 |

SS |

|

WRO |

3 |

5.632 |

0.008641 |

3.287 |

SS |

|

|

BSH |

CW |

5 |

38.504 |

4.88E-08 |

2.901 |

SS |

|

WRO |

3 |

25.081 |

4.28E-06 |

3.287 |

SS |

|

|

BSL - British standard light; BSH - British standard heavy; SS - statistically significant |

||||||

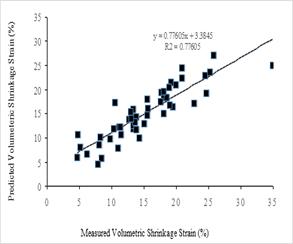

Regression analysis

The generation of functional model by multiple regression analysis of variables had been significantly used in geotechnical by several researchers [12, 26]. Mini-tab R15 software and XLSTART 2014 statistical tool integrated as an add-in in Microsoft Excel were used for the regression modeling and correlation analysis, respectively. The volumetric shrinkage strain (VSS) considered as the dependent variable was expressed as a function of the following independent variables: concrete waste (CW), molding water content (MWC), water content relative to optimum (WRO) and compactive effort denoted by compactive effort index (CE). The resulting regression equation obtained is expressed thus in Eq. [2].

![]() (2)

(2)

In Eq. (2), VSS, CW, MWC and WRO are expressed in percentages and CE is an integer categorical variable where CE was assigned the values -1 and + 1 for BSL and BSH compaction levels, respectively. Result of regression analysis show that all the parameters considered have effect on the volumetric shrinkage strain of the soil. The statistical parameters for the equation are given in Table 4. The coefficient of multiple determination, R2, for Eq. (2) is 0.776, while the adjusted R2 value is 0.755. The overall F-statistic (37.252) obtained is statistically significant at 95% confidence limit (i.e., α = 0.05). The p-value for CW, MWC, WRO as well as compactive effort were less 0.05. The coefficient of each constraint reveals the magnitude of the effect of the constraint on the volumetric shrinkage strain. Parameters having positive coefficients depict the fact that increase in these parameters will be directed towards corresponding increase in volumetric shrinkage strain of the compacted soil. On the other hand, independent variables having negative coefficients represent decrease in VSS with increase in such variable. Therefore, precautions must be taken to ensure these variables are properly controlled, regulated and managed at the site during ground improvement to realize a workable barrier system.

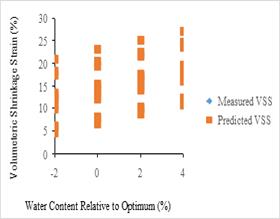

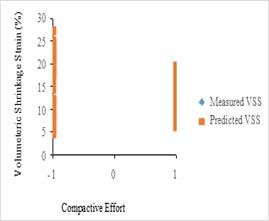

The effect of each of the variables on the VSS can be further explained using a line of fit plot to show the off-set or non-fitted points that exist in the variation of each variable with the measured and predicted VSS. The effect of WRO, CE, CW and MWC variables on the relationship between the outcome of VSS values measured from the laboratory and that of the predicted VSS from the model as shown in Eq. (2) is represented by the line fit plots (Figures 13 – 16). It is evident from the fit line plot that the effect of WRO and CE on predicted and measured values were completely and well fitted together (see Fig 13 and 14). This is an indication that the model yielded perfect predicted values of VSS from measured laboratory values with all (100 %) of points totally overlapped each other. These probably suggest that the response of WRO and CE variables on the predicted VSS did not show any significant variation from the measured laboratory result, respectively. The trend is that of a general increase in measured and predicted VSS with increased WRO and decrease in measured and predicted VSS with increased CE. For case of CW effect, it is obvious from the fit line plot that the model yielded almost perfect predicted values from models of measured laboratory values of VSS. The predicted and measured values having more or less unified fitted point (see Figure 15) but translates to a general increasing values of VSS up to a maximum of 35 and 22 % for measured and predicted values at a threshold of 20 % CW treatment, respectively based on the response of CW, it could be said that the results of measured and predicted VSS values did not show any significant disparities. The line fit plot of Figure 16 show that MWC variable which ranged from the -2% dry side to +4% wet side of the optimum MWC have significant effect the VSS of both measured and predicted values. From the foregoing, it could be suggested that the variable of MWC be strictly controlled and managed in the field during preparation of cover and liners in waste containment facility.

The association between the predicted and measured VSS values is shown in the graphical plot of Figure 17. The plot also provides a comparison between the predicted and measured values of VSS. The linear relationship of predicted values from the regression model and measured laboratory result of volumetric shrinkage strains shows a strong relationship between predicted values and measured laboratory result having correlation coefficient R2 = 0.776 (see Figure 17), which also depict that the regression function in Eq. (2) is adequate.

Table 4. Results of multiple regression analysis for volumetric shrinkage strain

|

Variables |

Coefficients |

t-statistic |

P-value |

Regression parameters |

|

Intercept |

-22.376 |

-4.009 |

0.000 |

R2 = 0.776 |

|

CW |

-0.083 |

-2.765 |

0.008 |

Adjusted R2 = 0.755 |

|

MWC |

2.008 |

7.497 |

0.000 |

Standard Error =3.067 |

|

WRO |

-0.975 |

-2.926 |

0.005 |

Overall F-statistic = 37.252 |

|

CE |

-1.058 |

-2.388 |

0.021 |

Observations = 48 |

|

Figure 13. Plots of VSS (measured and predicted) versus water content relative to optimum |

Figure 14. Fitted plots of VSS (measured and predicted) versus compactive efforts |

|

Figure 15. Fitted plots of VSS (measured and predicted) versus concrete waste content |

Figure 16. Fitted plots of VSS (measured and predicted) versus molding water content |

|

Figure 17. Relationship between predicted and measured volumetric shrinkage strains |

|

Correlation analysis of volumetric shrinkage strain

The correlation analysis for black cotton soil with VSS and the parameters related with VSS (CW; MWC and WRO) bares varying level of associations. The results of the correlation analysis, using XLSTAT are shown in Table 5 and 6. The correlation between VSS and the connected parameters of MWC and WRO were observed positive while negative correlation was observed between VSS and the related parameters of CW. The correlation coefficients, R, are relatively high (R ≥ 0.70) between volumetric shrinkage strain and compaction water content (MWC) on one hand and extremely low between CW and WRO on the hand. Complete results of coefficient of determination (R2) is shown in Tables 6.

Table 5. Correlation matrix (Pearson) for volumetric shrinkage strain with correlated parameters

|

Variables |

VSS |

CW |

MWC |

WRO |

|

VSS |

1 |

|

|

|

|

CW |

-0.586 |

1 |

|

|

|

MWC |

0.794 |

-0.330 |

1 |

|

|

WRO |

0.404 |

0.000 |

0.759 |

1 |

Table 6. Coefficient of determination, R2 (Pearson) for volumetric shrinkage strain with correlated parameters

|

Variables |

VSS |

CW |

MWC |

WRO |

|

VSS |

1 |

|

|

|

|

CW |

0.343 |

1 |

|

|

|

MWC |

0.631 |

0.109 |

1 |

|

|

WRO |

0.163 |

0.000 |

0.576 |

1 |

|

Volumetric shrinkage strain (VSS); Concrete waste (CW); Moulding water content (MWC); Water content relative to optimum (WRO) |

||||

Conclusions

Laboratory tests were conducted on Black cotton soil treated with up to 50% construction waste content to assess desiccation effect on the compacted material for use as a hydraulic barrier in waste containment facility. The treated soil was compacted using British standard light (BSL) and British standard heavy (BSH) at moulding water contents of -2, 0, 2 and 4% of the respective optimums. The shrinkage strain values were recorded within the first five (5) days of drying and became constant by the 15th day. Volumetric shrinkage strain increased with higher moulding water and moulding water content relative to optimum, while it decreased with higher compaction effort. Volumetric shrinkage strain generally decreased with higher percentages of construction waste. Consequently, none of the materials fell within the acceptable range of less than or equal 4%. Volumetric shrinkage decreased with higher construction waste treatment at all moulding water content regardless of the relative effect compaction effort.

References

1. Ferguson J., Kermode N., Nash C.L., Sketch W.A.J., and Huxford R.P., Managing and minimizing construction waste: A practical guide, Institute of Civil Engineers, London, 1995.

2. Faniran O.O., Caban G., Minimizing waste on construction project sites. Engineering Construction and Architectural Management Journal, 2007, 5 (1), p. 182-188.

3. Lim T., Chu J., Assessment of the use of spent copper slag for land reclamation. Waste Management and Research, 2006, 24 (1), p. 67-73.

4. Daniel D.E., Wu Y.K., Compacted clay liners and covers for arid site, J. Geotech. Engrg. ASCE, 1993, 119 (2), p. 223 – 237.

5. Khire M.V., Benson C.G., Bosscher P.J., Water balance modeling of earthen landfill covers, J. of Geotech and Geoenvir. Eng. A.S.C.E., 1997, 123 (8), p. 744–754.

6. Corser P., Cranston M., Observations on the performances of composite clay liners and covers, Proc. Geosynthetic Des. And Perf., Vancouver Geotechnical Society. Vancouver, B.C., 16, 1991.

7. Benson C., A review of alternative landfill cover demonstrations, Envir. Geotech. Rep. 97-1, Depth of Civil and Envir. Eng., University of Wisconsin-Madison, 1997.

8. Benson C.H., Khire M., Earthen materials in surface barriers, Barrier Technologies for Environmental Management, National Academy Press, National Research Council, D79–D89, 1997.

9. Daniel D.E., Benson C.H., Water content density criteria for compacted soil liners, Journal of Geotechnical Engineering, 1990, 116 (12), p. 1811-1830.

10. Kumar S., Use of construction and demolition waste - A way forward, Indian Roads Congress, 2015, 43 (1), p. 13-17.

11. Daniel D.E., Geotechnical practice for waste disposal, Chapman & Hall, London, UK, 1993.

12. Osinubi K.J., Nwaiwu C.M.O., Desiccation-induced shrinkage in compacted lateritic soils. Geotechnical and Geological Engineering, 2008, 26 (5), p. 603–611.

13. A.A., Eberemu A.O., Potential application of lateritic soil stabilized with cement kiln dust (CKD) as liner in waste containment structures, Geotechnical and Geological Engineering, 2013, 31 (4) p. 1221–1230.

14. Umar S.Y., Elinwa A.U., and Matawal D.S., Hydraulic conductivity of compacted lateritic soil replaced with metakaolin, Journal of Environmental and Earth Science, 2015, 5, p. 53–64.

15. American Association of Stat E Highway and Transportation Officials, AASHTO Materials, Part I, Specifications, Washington D.C., 1982.

16. ASTM: Annual book of ASTM standards, vol. 04.08, 1992, Philadephia.

17. BS 1377: Methods of testing soils for civil engineering purposes, British Standard Institution, London, 1990.

18. BS 1924: Methods of test for stabilized soils. British Standards Institute, London.1990

19. Osinubi K.J., Yohanna P., Eberemu A.O., Cement modification of tropical black clay using iron ore tailing as admixture, Journal of transportation Geotechnics. 2015, 5, p. 35-49.

20. Etim R.K., Eberemu A.O., Osinubi K.J., Stabilization of black cotton soil with lime iron ore tailings admixture, Journal of Transportation Geotechnics. Elsevier, 2017, 10, p. 85 – 95. http://dx.doi.org/10.1016/j.trgeo.2017.01.002

21. Albrecht B.A., Benson C.H., Effect of desiccation on compacted natural clay, J. Geotech & Geoenvir. Engrg., ASCE, 2001, 127 (1), p. 67 – 75.

22. Osinubi K.J., Eberemu A.O., Desiccation induced shrinkage of compacted lateritic soil treated with blast furnace slag, Journal of Geotechnical and Geological Engineering, 2010, 28 (5), p. 537 – 547.

23. Eberemu A.O., Desiccation induced shrinkage of compacted tropical clay treated with rice husk ash, International Journal of Engineering Research in Africa, 2011, 6, p 45-64. doi:10.4028/www.scientific.net/JERA.6.45.

24. Mitchell J.K., Fundamental of soil behavior, John Wiley and Sons Inc. New York, 1976.

25. Haines W. B., The volume changes associated with variations of water content in soils, The Journal of Agricultural Science, 1923, 13 (3), p. 296 – 310.

26. Bassey O.B., Attah I.C., Ambrose E.E and Etim R.K., Correlation between CBR values and index properties of soils: A case study of Ibiono, Oron and Onna in Akwa Ibom State, Resources and Environment, 2017, 7 (4), p. 94-102.

Figure 7. Plot of mass with time of

volumetric shrinkage at the OMC for 40% CW content

Figure 7. Plot of mass with time of

volumetric shrinkage at the OMC for 40% CW content Figure 8. Plot of mass with time of

volumetric shrinkage at the OMC for 50% CW content

Figure 8. Plot of mass with time of

volumetric shrinkage at the OMC for 50% CW content