Engineering, Environment

Development and performance evaluation of an improved electric baking oven

Temitope Olumide OLUGBADE *, Oluwole Timothy OJO

Department of Industrial and Production Engineering, School of Engineering and Engineering Technology, Federal University of Technology, PMB 704, Akure, Ondo State, Nigeria

E-mail(s): *tkolugbade@gmail.com; wolex025@gmail.com

* Corresponding author, +2348068859326

Received: December 05, 2017 / Accepted: November 28, 2018 / Published: December 30, 2018

Abstract

The development of an improved electric baking oven was carried out and its performance was evaluated to determine its effectiveness and functionality. A thermostat and interlock switch were incorporated to improve on the already existing oven. Compared with the existing ones, the improved electric baking oven is efficient, faster, and thus baked effectively. The performance evaluation test revealed the moisture content of 67.7%. The power of the electric heating element is greater than or equal to 0.3745 kW. The improved electric baking oven operates on the principle of electric resistance and the resistance of the heating element was obtained to be 0.64 Ω. The heating element could supply a minimum of 1,797.6 KJ of heat energy to the oven chamber in 80 minutes. By this, the standard temperature in drying could be determined, an electrically operated oven with monitored heat supply could be produced and a method of producing dry materials in large quantities and at a reduced cost can be proposed.

Keywords

Electric baking oven, thermostat, interlock switch, heating element, drying

Introduction

The study on electric baking oven has received a considerable attention over the decades, due to its durability, efficiency and availability. It is a heating chamber, thermally insulated enclosure, or small furnace which is basically used for the extraction of moisture from some engineering materials to improve their mechanical properties such as hardness and ductility. It can also be used for material processing, heat treatment of engineering materials and sterilization of equipments and instruments for industrial use [1-3]. However, it should be noted that the existing baking oven takes much time because of the long waiting time of the users to have their foods ready. Also, the efficiency is very low and not up to standard.

Hence, to improve the performance and efficiency of the existing oven, there is need to develop an improved electric baking oven through the incorporation of thermostat and interlock switch. Compared to other types of oven which include gas, earth, ceramic, and masonry oven, an electric baking oven is readily available, relatively cheap, easy to install and maintain, portable, has a very easy mode of operation with high durability [1, 3].

In the present work, an electric baking oven is chosen as the subject of investigation due to its daily need and high market demands. It will also the solve the problem often experienced in drying as well as finding a lasting alternative to replace the use of gas or kerosene cooking and drying which are often not readily available in the market for human use. It consists of three major parts; insulated box, heating elements and cables or controls.

The insulator box acts as the housing element where items to be baked stays. The heating element is incorporated with a thermostat to regulate the rate of heat generation in the system while the control or cables regulates the current flow to the heating element to prevent the supply of excess heat and avoid over- roasting or burning.

The basic operational principle of the electric oven is the process of heat transfer [4]. The baking process usually requires significant energy consumption as relatively high temperature is applied to remove moisture in bakery products and create desired texture. In general, oven temperature varies according to ingredients used to make the food substance.

The baking time, however, depends on the size and shape of the food substance as well as the temperature of the oven.

Several works have been carried out on baking oven due to its importance and ease of operation. Genitha et al. [1] developed a domestic gas oven by which a higher energy efficiency was obtained by reducing the energy, cost and the time of baking. In a related work, Adegbola et al. [3] developed a low cost domestic electric baking oven with the incorporation of a blower for improved efficiency. In another study, Therdthai et al. [2] designed an efficient and cheap gas oven by using the software 3D solid works which shows the pictorial views, lines, and dimensions for the fabrication. In the fabrication process, the major design considerations were considered as emphasized by other researchers [5-9, 14-17].

However, the efficiency of the electric baking oven as well as the working mechanism for better efficiency has not been well researched and hence need further. In addition, to minimize energy consumption, analysis and optimization of baking process and equipment have not been properly done hence further work is needed.

In the present study, an improved electric baking oven was designed and fabricated, which is portable, efficient and cheaper than the existing ones. The improvement was done by incorporating a thermostat and interlock switch.

The operating factors that are to be considered for the design of an electric oven were identified and its performance was well evaluated. By this, the standard temperature in drying could be determined, an electrically operated oven with monitored heat supply could be produced and a method of producing dry materials in large quantities and at a reduced cost can be proposed.

Material and method

Materials and selection criteria

Improved electric baking oven was designed and fabricated. It consists of thermostat, housing unit, light indicator, timer and heating element and interlock switches.

The factors considered in the selection of materials include; mechanical properties such as strength, hardness, durability; cost, availability, and electrical properties.

Working principle of an electric oven

The heating element generates heat and the heat generated is dissipated within the oven chamber. By convection, it is transferred to the metal pans placed on the wire mesh. Greater heat is transferred to the dough mainly by conduction since the food substance is in direct contact with the pans. To prevent excess heat and over- roasting or burning, the thermostat regulates current flow to the heating element.

The basic operational principle of the electric oven is the process of heat transfer. Heat transfer through conduction, convection and radiation, tends to occur whenever there is a temperature difference.

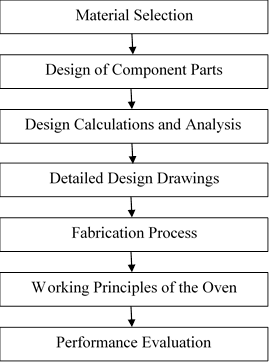

The working procedures adopted in the development and performance evaluation of the improved electric baking oven are illustrated in Figure 1.

Figure 1. Working algorithm for the improved electric baking oven

As shown in Figure 1, the working algorithm for the improved electric baking oven include the material selections, design of component parts, design analysis and calculations, detailed design drawings, process of fabrication, working principle and performance evaluation.

Conduction

Conduction of heat food substance is due to impact of adjacent molecules that vibrate internal radiation. The heat basically flows from hotter end to the coldest end and the greater the temperature difference, the faster the heat will flow. This is determined using Fourier's law of conduction in one dimensional state,

Mathematically expressed as, Eq. [1]:

![]() (1)

(1)

Where: Q - the rate of heat flows in Kw (KJ/secs), K - thermal conductivity of the material (W/mk), DT - temperature difference between the surfaces of metal, DX - thickness of the material (m), A - area of the section at right angle (m2).

Convection

By convention process, energy is transfered from one point to another by the motion of a mass of materials between the two points.

Mathematically, it can be expressed as, Eq. [2].

Q = LA [![]() ]

(2)

]

(2)

Where: L - coefficient of corrective heat transfer, A - area

of surfaces not perpendicular to direction of heat flow, ![]() -

thermal temperature.

-

thermal temperature.

In the developed oven, the fluid involved is the enclosed air and the heating element or burner surface, which provides the sold surface, while the oven walls serve as the solid surfaces.

The rate of heat transfer across an enclosed space (oven) is calculated from a coefficient based upon the temperature differences of the surfaces.

Radiation

As this type of heat transfer requires no materials medium, it is accomplished by means of wave motion through space. All objects can emit and absorb radiation, and radiation carries energy (W).

The total radioactive flux throughout the hemisphere from the black surface of area “A” and absolute temperature T is given by the Stefan- Boltzman law.

Mathematically, it can be expressed as, Eq. [3].

Q =Aσ![]() (3)

(3)

Where: Q - heat flux, energy per time, A - area of heat flux intensity, σ - Stefan Boltzman constant (5.67 x 10 -8) 10/m 2 (K4), T - absolute temperature.

Table 1 shows the various parts of the improved electric baking oven, the materials and quantity.

Table 1. Various parts of the oven, the materials and quantity

|

S/N |

Part Names |

Materials |

Quantity |

|

1 |

Oven Lock |

Galvanized steel |

1 |

|

2 |

Oven Door |

galvanized steel |

1 |

|

3 |

Door Handle |

Iron Rod |

1 |

|

4 |

Insulator |

Rock wool |

1 |

|

5 |

Nut |

Iron` |

1 |

|

6 |

Insulator |

Plastic |

1 |

|

7 |

Top cover |

Galvanized steel |

1 |

|

8 |

Air Hole |

|

1 |

|

9 |

Plug |

Plastic |

1 |

|

10 |

Oven wall |

Galvanized steel α Fibre |

4 |

|

11 |

Oven Stand |

Pipes (galvanized steel) |

4 |

|

12 |

Electrical Housing |

Galvanized steel |

1 |

|

13 |

Thermostat |

Various |

1 |

|

14 |

Indicator Light |

Plastic |

1 |

|

15 |

Electrical Wire |

Cable |

4 |

|

16 |

Layer Net |

Iron rod |

1 |

|

17 |

Layer Net |

Galvanized Steel |

1 |

The parts include the cover, oven door, door handle, insulator, nut, oven lock, electrical housing, interlock switches, etc. The parts are majorly made of galvanized steel, iron rod, rock wool, plastics, cable, etc.

Table 2 shows the operation stages followed in the production of the improved electric baking oven.

Table 2. Operational sequences/stages

|

S/N |

Operation |

Descriptions |

Tools |

|

1 |

Material collection |

Prompt collection and distribution of the materials for the constitution and installation of the parts |

Free hand |

|

2 |

Measurement of parts |

Proper making out the measured points on the mild |

Scriber meter rule |

|

3 |

Drilling (Hand drilling), Clamping, Welding Operation |

Drilling of hole on the front view i.e. facade view at the lower part of the oven. Another hole was made on the rear side (back view) at the upper part. |

Bench vice drill bit and electrical welding machine |

|

4 |

Cutting Riveting |

Proper cutting of the same material to the electrical compound, to dimension and rivet the pins to the joints. |

Plate cutting machine, riveting machine, hammer and rivet pin. |

|

5 |

Bending |

Parts bending as shown in the AutoCAD design |

Plate bending machine |

|

6 |

Installation |

Electrical installation of component to it unit. |

Screw driver and tester. |

|

8 |

Insulation |

Putting fibers into the oven walls as shown in the AutoCAD design before welding operation |

Free hand |

|

9 |

Welding Riveting |

Adequate welding of the mechanical unit to food chamber and joining the electrical unit to the mechanical unit by riveting the pins |

Electrical welding machine. |

|

10 |

Welding Electrical connection |

Proper fixing of the element to the interior part of the oven and fixing of the blower, rotor to it housing as shown in the AutoCAD design. |

i. Electric welding machine ii. Free hand for the connection |

|

11 |

Electrical Connectivity |

Electrical wire connection from the electrical component to the heating place at the interior side and to the motor at the back view of the oven (rotor housing). |

Free hand |

|

12 |

Painting |

Painting of the entire interior and exterior views of the baking oven as shown when seen. |

Painting brush |

|

13 |

Electrical connectivity |

Insertion of the into the socket |

Free hand |

The operation ranges from material collection, measurements and basic machining and finishing operations, electrical connections and insulation, painting, cleaning and other finishing processes.

Design calculation

The heat transfer co-efficient, between

solid, at a temperature![]() and

and![]() which

is the outermost sheet metal temperature separated by an insulator (rock wool)

is illustrated as Eq. [4-7].

which

is the outermost sheet metal temperature separated by an insulator (rock wool)

is illustrated as Eq. [4-7].

q = UA (![]() ) (4)

) (4)

UA =![]()

![]() (5)

(5)

![]() (6)

(6)

![]() (7)

(7)

![]()

Where: q - heat transfer co-efficient, Th - temperature of a solid, Tc - outermost sheet metal temperature, A1 - area of a solid, A2 - area of the outermost sheet metal, Q - total rate of heat transfer, Ch - specific heat capacity of a solid, Cc - outermost sheet metal specific heat capacity, Mc - outermost sheet metal mass.

The total rate of heat transfer rate between two solids is given as, Eq. [8-10].

Q =![]() (8)

(8)

ln![]() (9)

(9)

![]() (10)

(10)

Where: Q – total rate of heat transfer, A - area of the material.

The quantity of heat required to bake the paint metal is illustrated as, average baking (oven) temperature (2500C, 523K), let Mb (mass of substance, 5000 g), Cb (specific heat capacity of substance, 450 J/Kg-1K-1) and TRM (Oven room temperature, 280C = 301 K), Eq. [11].

![]() =

401.8K (11)

=

401.8K (11)

Therefore, the logarithmic mean temperature

difference between the solid at a temperature (Th) and![]() the

outermost sheet metal temperature (Tc) separated by an insulator

(rock wool) is 401.8K.

the

outermost sheet metal temperature (Tc) separated by an insulator

(rock wool) is 401.8K.

Heat required (QH) was calculated to be 1,498KJ. This is the quantity of heat required to bake the minimum of three paint metals per batch, Eq. [12].

QH = MCθ![]() (Vogel,

2016) (12)

(Vogel,

2016) (12)

QH = ![]() x

x![]() x

TRM

x

TRM

Where: QH - heat required, Mb - mass of the substance, Cb - specific heat capacity of substance, TRM - oven room temperature.

Determination of the capacity of electric heating element

The power of the electric heating element is determined as follows, Eq. [13].

P = Energy / Time (13)

Where: P - Rate of expenditure of Energy, average processing time per batch (80 minutes),

Quantity of heat supplied to the oven chamber (1,498 KJ), considering 80% heat transfer to the paint metal (Heat = 1.2 x 1,498KJ =1,797.6KJ)

This means that the heating element should supply a minimum of 1,797.6 KJ of heat energy to the oven chamber in 80 minutes.

Thus, power of electric heating element ≥ 0.3745 kW, Eq. [14-15].

![]() (14)

(14)

![]() (15)

(15)

Where: P - power (W), I - current (A), V - voltage (V), R - electric resistance (Ω).

Work done, or energy expended is given by, Eq. [16].

![]() (16)

(16)

Where: t - time (s), V - voltage (V), I - current (A).

Compared with the previous results [1-3],

the resistance of the heating element is 0.64 Ω, current is 1.56 A while

the cable size is 2.5![]() .

.

Design drawing

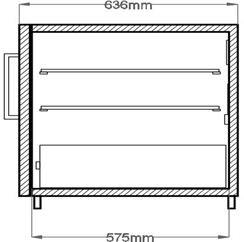

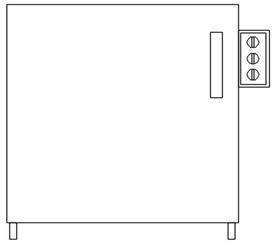

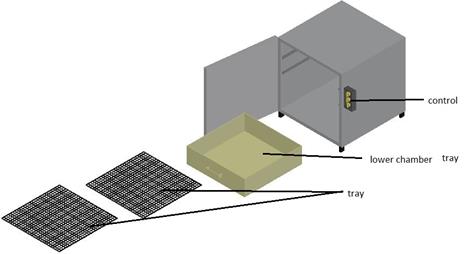

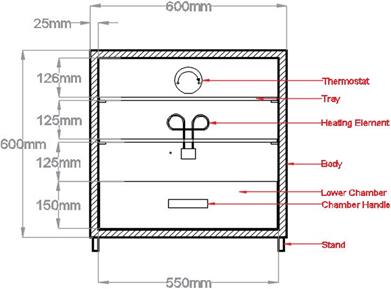

The design drawings are illustrated in Figures 2-6. Figure 2 shows the pictorial view of the improved electric baking oven while the exploded view is illustrated in Figure 3.

Figure 2. Design drawing (pictorial) of the electric baking oven

Figure 3. Exploded view

Figure 4 shows the isometric view (when closed) of the oven while Figure 5 and Figure 6 show sectional view, the front and sectioned front view of the oven respectively.

Figure 4. Isometric view (when closed) of the oven

Figure 5. Sectioned view of the oven

|

|

|

Figure 6. Front and sectioned front view of the oven

Results and discussion

The galvanized steel sheets were coupled together by means of welding operation and insulated by rock wool in other to prevent heat loss to the frame.

The welded parts must be made smooth to prevent unwanted injuries after body scratching against the oven. Finishing of a product determines attractiveness. It was observed the drying electric oven heats up to 2500C and the ambient temperature 300C.

The fish substance was placed inside the improved baking electric oven on a tray, after which the temperature a regulated to a stipulated temperature control, in other to maintain the given temperature of 500C.

At some point the fish started to take a longer period to get heated up, later the temperature was increased to 1000C, which took 20 mins to bake, and got dried afterwards, which is similar to the previous results [1-3, 10-12].

It was observed that the oven tripped after it attained a level, and this was because of the censor present that senses a usual heating, the heating was aided by the thermocouple It as discovered that the colour does not in any way affect the oven since it is lagged. The developed oven was painted cream.

Performance evaluation

The performance of the improved electric baking oven was evaluated by using the machine to dry food substance (fish).

The weight of the fish before drying and after drying was determined using weighing balance and the moisture content of the fish was determined by Eq. [15] (maximum temperature of the oven = 2500C, ambient temperature = 300C, weight of the fish before drying = 3, weight of the fish after drying = 2)

Moisture content = ![]() (15)

(15)

Where: A - weight of the fish before drying, B - weight of the fish after drying, therefore, moisture content. The performance evaluation test revealed the moisture content of 67.7%.

Figure 7 shows the performance evaluation process i.e. oven, the heating element, the setting of the tray and the substance to be fried. The body of the oven was checked, and it was confirmed that it was well insulated and properly lagged.

The electric drying oven was put to test to determine its function-ability and effectiveness through some substances such as fish.

The experiment was performed for each of them while measurement was taken with respect to corresponding temperature and time-taken for turning level of the thermostat knob or timer and the temperature control switch that is graduated between low, medium and high is constantly maintained at high throughout the experiment.

|

|

|

|

|

Figure 7. (a) Oven when closed preparing to bake the substance, (b) The heating element getting heated up, (c) Setting the substance onto the tray, (d) Substance when placed into the oven

It should be noted that the optimum baking temperature, weight loss, baking efficiency, and baking capacity are the important parameters in adequately estimating the performance and efficiency of the improved electric baking oven. With the moisture content of 67.7%, oven maximum temperature of 2500C, and ambient temperature of 300C, the performance and efficiency of the improved baking oven markedly improved compared to the existing ones in terms of efficiency and cost.

The results showed that, the improved electric baking oven can be adopted for baking of fish, meat, and bread at commercial and domestic levels.

From Figure 1, the improved electric baking oven is made of several compartments and is spacious to accommodate several baking substances at the same time. From the results obtained, it is obvious that the time required to cook the food reduces as the temperature increases which means the temperature is inversely proportional to time. In addition, as compared with the already existing oven, it can be deduced that the designed project is faster and thus baked effectively.

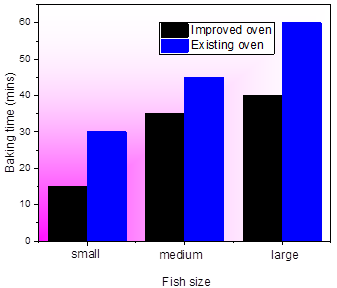

Figure 8 shows the comparison between the performance and baking time of the improved electric baking oven and the existing oven using different sizes of fish as case study.

Figure 8. Comparison between the performance and baking time of the improved electric baking oven and the existing oven.

Considering the existing oven [3], the small, medium and large sizes of fish used exhibited the baking time of 30, 45, and 60 mins, respectively. In the present study, the improved electric baking oven exhibited lower baking time of 15, 35 and 40 mins for small, medium and large fish size respectively.

These results show that there is a significant reduction in baking time with the improved electric baking oven presented in the present study.

The weight loss

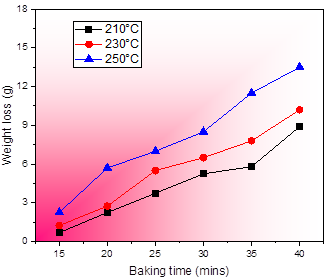

Figure 9 shows the relationship between the weight loss (g) and the baking time (min) at baking temperatures of 2100C, 2300C, and 2500C, during the baking process of fish.

Figure 9. Relationship between the weight loss (g) and the baking time (min) at baking temperatures of 230°C, 230°C, and 230°C

The weight loss was determined by the difference in mass of the baking substance before and after baking. It is obvious that the baking temperature increased with increase in the weight loss. In addition, with increase in baking time from 15 mins to 45 mins, an increase in the weight loss was achieved.

At the baking time of 20 mins, the minimum weight loss of 2.25 g, 2.75 g, and 5.7 g were obtained at the baking temperature of 2100C, 2300C, and 250°C, respectively.

During the baking process, a significant weight loss was observed at the baking temperature of 2500C.

The reduction in weight of the fish can be attributed to the increase in moisture loss observed during the baking process. Carvalho and Martins [11] reported the similar increased in weight loss using a forced convention baking oven. A similar moisture loss was observed by Genitha et al [1] using domestic gas oven.

Conclusions

In the present work, an improved electric baking oven which is portable, efficient and cheaper than the existing ones was designed and fabricated by incorporating a thermostat and interlock switch. The performance evaluation of the fabricated machine was thereafter carried out. The performance evaluation test revealed the moisture content of 67.7 %.

The power of electric heating element is greater than or equal to 0.3745 kW. The electric oven works on the principle of electric resistance and the resistance of the heating element was obtained to be 0.64 Ω.

The results obtained suggested that the heating element could supply a minimum of 1,797.6 KJ of heat energy to the oven chamber in 80 minutes. By this, the standard temperature in drying could be determined, an electrically operated oven with monitored heat supply could be produced and a method of producing dry materials in large quantities and at a reduced cost can be proposed.

In conclusion, the oven temperature varies according to ingredients used to make the substance. The baking time however, depends on the size and shape of the substance as well as the temperature of the oven. An efficient and faster electric oven was developed which does not blacken the baking pan and it is pollution free.

Acknowledgements

The authors would like to appreciate the effort of Ogunde Titilope who contributed immensely towards the success of this work.

References

1. Genitha I., Lakshmana G.B.T., John D.R., Design, Fabrication and performance evaluation of domestic gas oven, IOSR Journal of Engineering (IOSRJEN), 2014, 4 (5) p. 35-38.

2. Therdthai N., Zhou W., Thomas A., Three-dimensional CFD modelling and simulation of the temperature profiles and airflow patterns during a continuous industrial baking process, Journal of Food Engineering, 2003, 65, p. 599–608.

3. Adegbola A.A., Adogbeji O.V., Abiodun O.I. and Olaoluwa S., Design, construction and performance evaluation of low cost electric baking oven, Innovative Systems Design and Engineering, 2012, 3 (11) p. 38-49.

4. Dales H, George H., Excavations at Balakot, Pakistan, Journal of Field Archaeology (Boston University), 2015, (1-2) p. 3-22.

5. Akinnuli B.O., Olugbade T.O., Development and performance evaluation of piggery and water hyacinth waste digester for biogas production, International Journal of Engineering and Innovative Technology (IJEIT), 2014, 3 (10), p. 271 – 276.

6. Akinola A.O., Olugbade T.O., Adamolekun T.M., Development of a 3-Seater chair-bed, International Journal of Engineering and Innovative Technology (IJEIT), 2014, 4 (1) p. 177 – 181.

7. Mohammed T.I., Olugbade T.O., Odesanmi G.A., Development and performance evaluation of a pedal operated hydraulic jack, Journal of Scientific Research and Reports (JSRR), Sciencedomain International, 2015, 8 (2), p. 1 – 8.

8. Ogedengbe T.I., Olugbade T.O. and Olagunju O.R., Application of house of quality matrix to material selection for engineering designs, British Journal of Applied Science and Technology (BJAST), Sciencedomain International, 2015, 10 (4), p. 1 – 11.

9. Olugbade T.O., Mohammed T.I. and Ojo O.T., Static stress analysis and displacement of a tricycle rear shock absorber using finite element analysis, Leonardo Electronic Journal of Practices and Technologies, 2018, 33, 165-184.

10. Ozilgen M., Heil J.R., Mathematical modelling of transient heat and mass transport in a baking process. Journal of Food Processing and Preservation, 1994, 18, p. 133–148.

11. Carvalho M., Martins N., Mathematical modelling of heat and mass transfer in a forced convection baking oven, AICHE Symposium Series – Heat Transfer, 1993, 88, p. 205–211.

12. Tong C.H., Lund, D.B., Effective moisture diffusivity in porous materials as a function of temperature and moisture content, Biotechnology Progress, 1990, 6, p. 67–75.

13. Fellows P.J., Food processing technology principles and practice, Wood head Publishing Limited, Cambridge, 2000.

14. Abioye T.E., Olugbade T.O. and Ogedengbe T.I., Welding of dissimilar metals using gas metal arc and laser welding techniques: A Review, Journal of Emerging Trends in Engineering and Applied Sciences, 2017, 8 (6), p. 225-228.

15. Akinnuli B.O and Olugbade T.O., Application of queue model for performance assessment of multi-channel multi-servers motor spirit filling station, International Journal of Engineering and Innovative Technology, 2014, 3 (7), p. 74 – 81.

16. Mohammed T.I., Nwankwo I.C. and Olugbade T.O., Determination of the effect of oil exploration on galvanized steel in Niger Delta, Nigeria, Journal of Scientific Research and Reports, 2016, 10 (1), p. 1 – 9.

17. Ojo O.T., Olugbade T.O., Development of an adjustable multi nut tighter or remover for car tyre, Leonardo Electronic Journal of Practices and Technologies, 2018, 32, p. 27-40.